Wood-emulating floor and its manufacture method

A technology of imitating solid wood and flooring, which is applied in the direction of manufacturing tools, building structures, wood processing appliances, etc., and can solve the problems of poor surface gloss, poor clarity, and affecting use effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

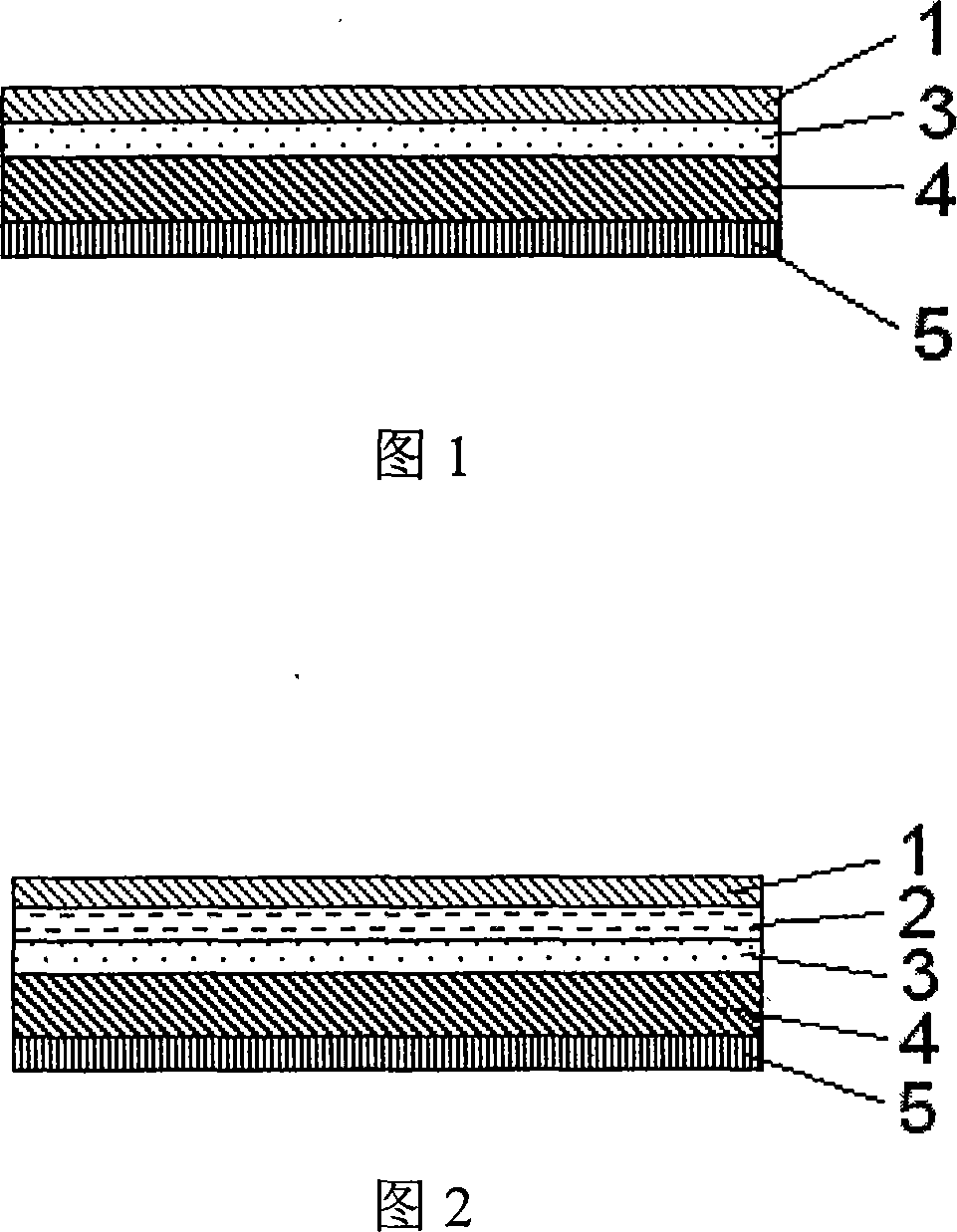

[0017] Fig. 1 shows a sectional structure state of the imitation solid wood bottom plate of the present invention. The surface and back of the medium / high density fiber material core layer structure 4 are respectively covered with a surface structure layer and a moisture-proof balance structure layer 5, wherein the surface structure layer is composed of a wear-resistant paint layer 1 and a decorative bottom layer 3 on the surface.

[0018] In the surface structure layer, the wear-resistant paint layer 1 on the surface is a paint layer in the form of piano paint, violin paint or UV paint mixed with aluminum oxide abrasive or liquid wear-resistant material in a dispersed state. The decorative bottom layer 3 can be a decorative texture formed by printing or transfer printing on the surface of the density fiber material core layer 4, or can be a wear-resistant decorative paper layer coated with wear-resistant materials such as aluminum oxide.

[0019] The moisture-proof balance la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com