Crawler type all-hydraulic tunnel drilling rig hydraulic system for coal mine

A technology of tunnel drilling rig and hydraulic system, which is applied in drilling equipment, earthwork drilling, mechanical equipment, etc., can solve the problems of low control precision, troublesome system control, low reliability, etc., and achieves high control precision, convenient operation and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

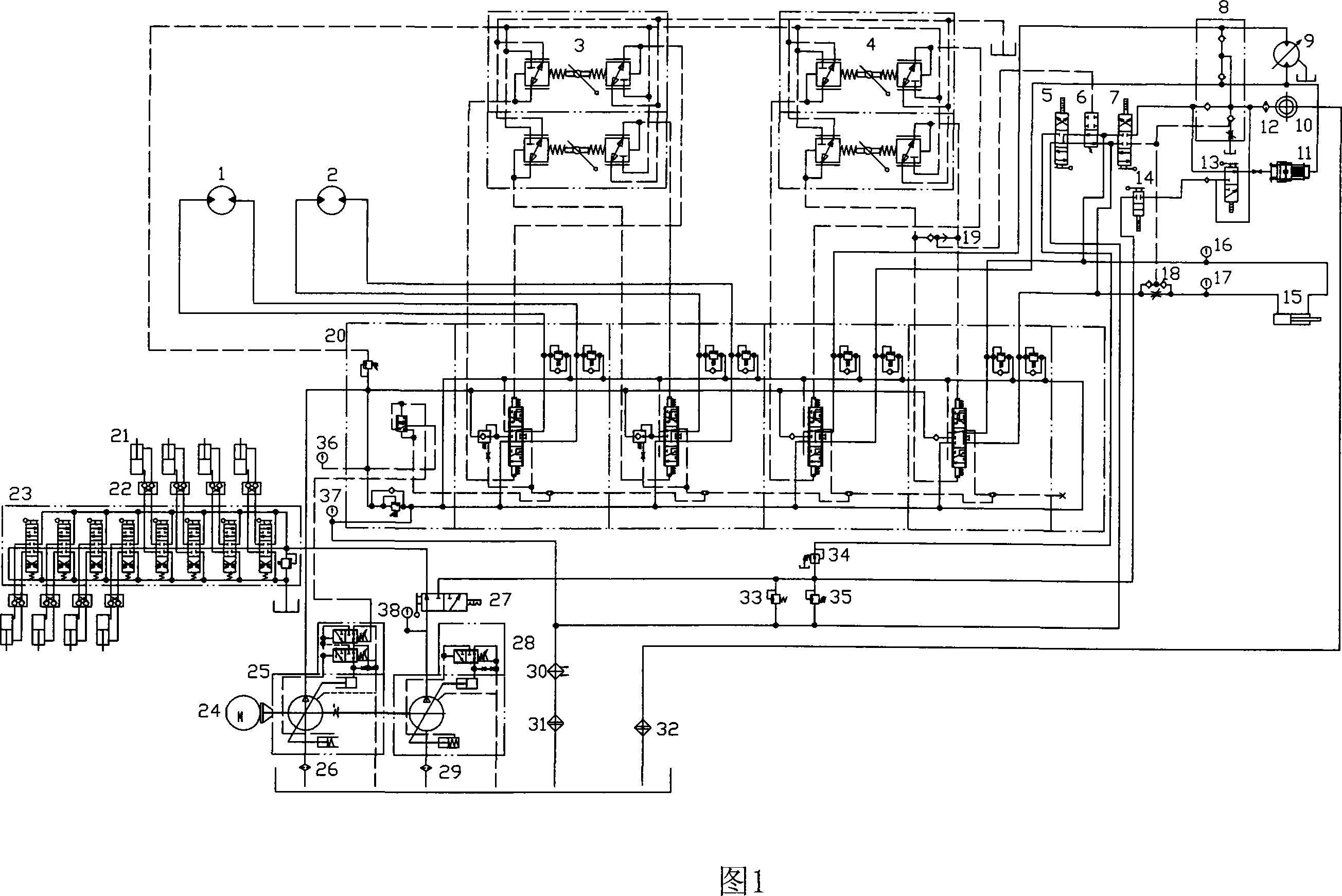

[0018] Referring to Fig. 1, the present invention applies the hydraulic control reversing valve and the remote control technology, and utilizes the connection relationship between various valves to form a linkage action to adapt to different drilling operations.

[0019] The hydraulic circuit of the hydraulic system is a group of two pumps, the input ends of which are respectively connected to the oil tank through the oil suction filter 26 and the auxiliary oil suction filter 29;

[0020] The output end of the main oil pump 23 is connected to the main multi-way reversing valve 20 through a pipeline, and the first two pipelines of the main multi-way reversing valve 20 are connected with the left and right travel motors 1 and 2 of the control crawler chassis for controlling The travel motor, the third pipeline is connected to the main engine power head motor 9 in rotation, and is used to control the rotation of the main engine power head motor, and the fourth pipeline is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com