Waste glass label remover

A technology of waste glass and glass shards, which is applied in the direction of mixers, dissolvers, mixers, etc. with rotating stirring devices, can solve the problems of unsuitable glass shard material flow treatment, useless recycling, etc., and achieve uniform wear, thorough wear, and delay The effect of continuing to deliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

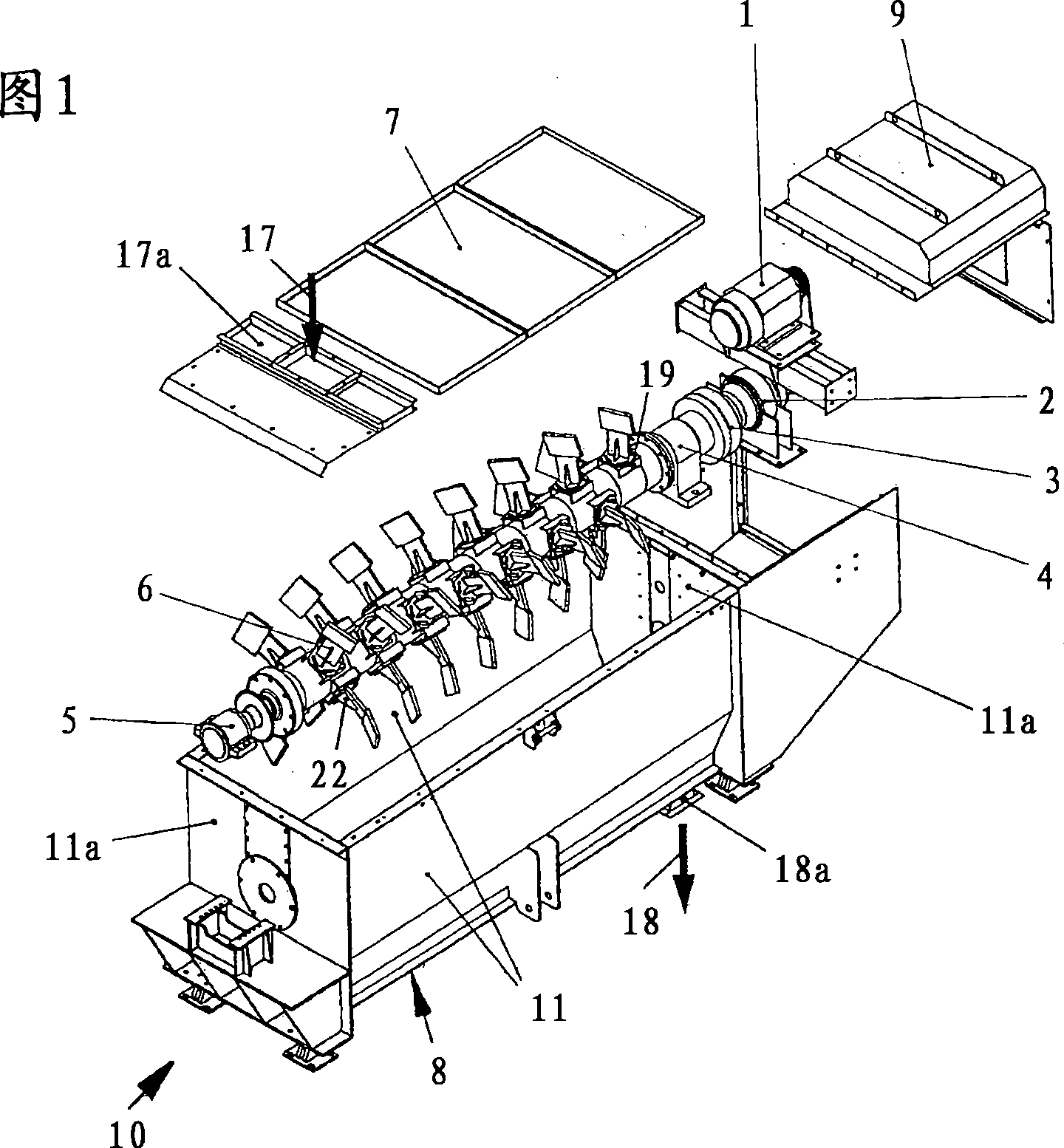

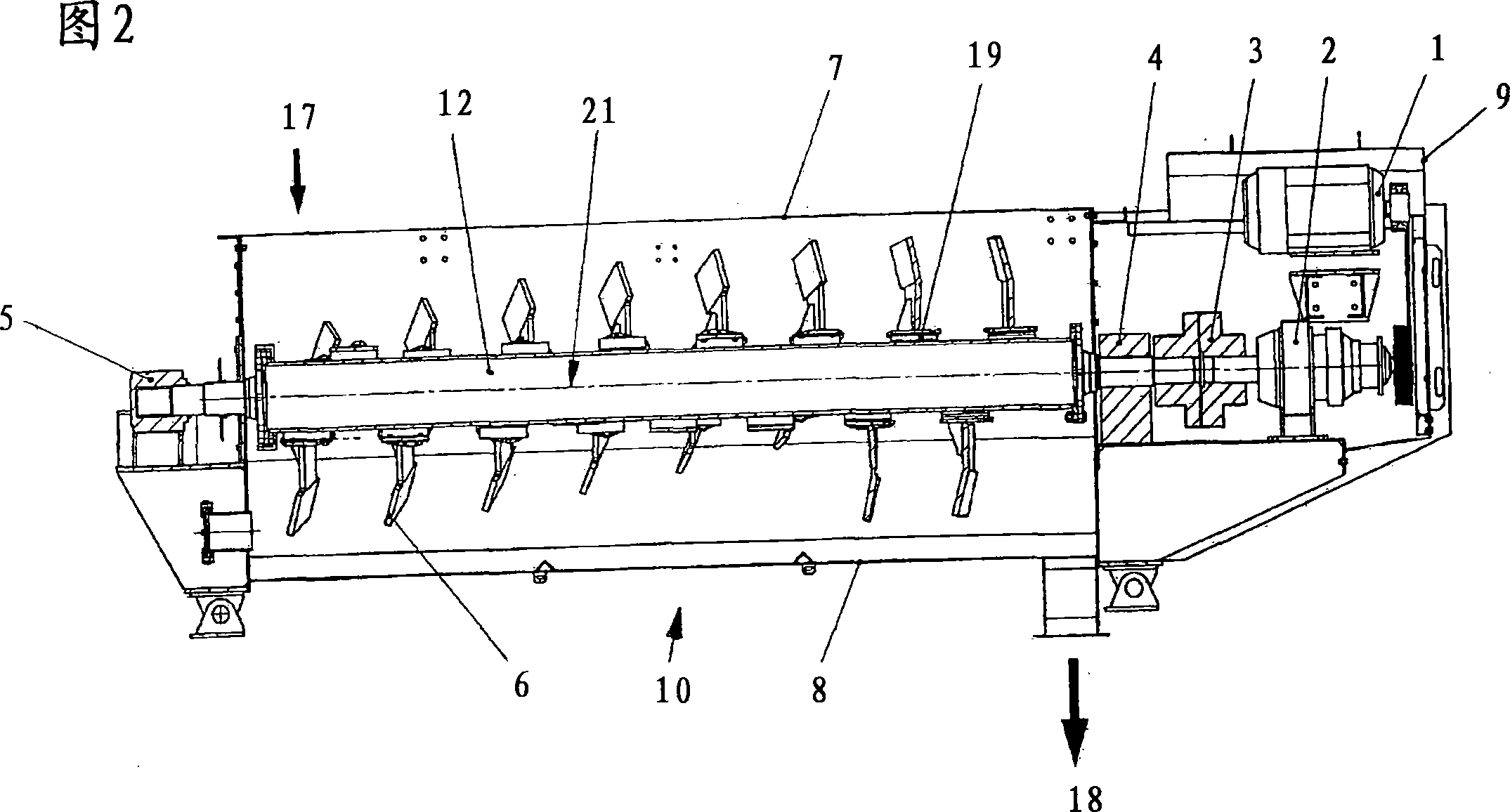

[0028] 1 and 2 show the apparatus for dry cleaning waste glass or glass fragments of the present invention, which comprises a driving device 1 , a shaft 12 and a plurality of blades 6 with a rotating track, a housing 10 and A coupling 3 and a reducer 2. The housing 10 includes side walls 11 and end walls 11 a , a bottom 8 and a shaft cover 7 and a drive cover 9 .

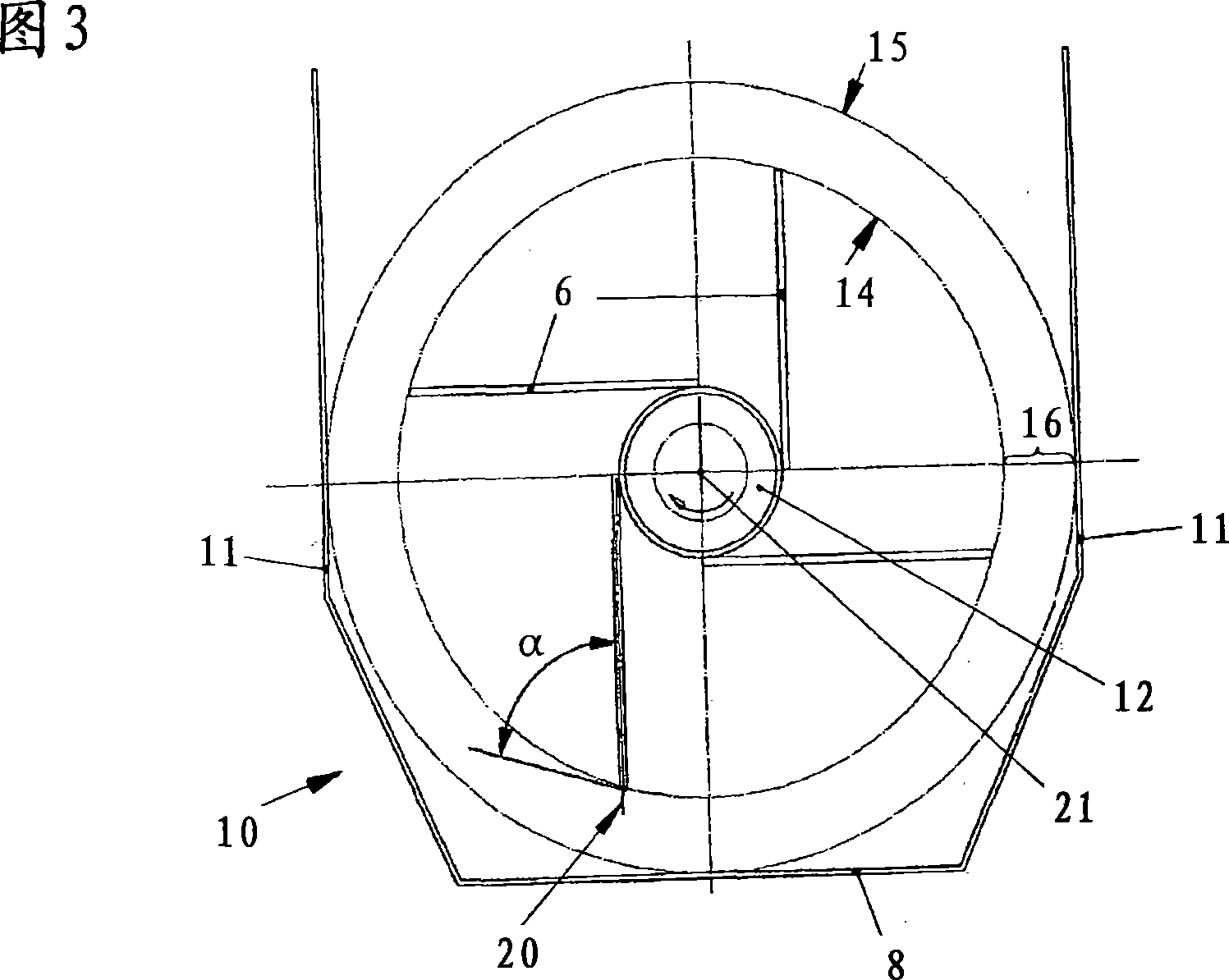

[0029] According to the invention, only a single shaft 12 is provided in the housing 10 , which has a plurality of blades 6 , the rotating track 14 of each blade 6 has a side wall 11 and a bottom 8 opposite the housing 10 according to FIG. 3 or 4 . A defined minimum spacing 16 of at least 3 cm, but preferably 5 cm. The shaft 12 is here arranged centrally on the end wall 11a and fits in a main bearing 4 and one end bearing 5 at its axial ends. The rotational speed of the shaft 12 can be varied via the drive 1 together with the coupling 3 and the reduction gear 2 as required with regard to the size and number of gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com