Textile machine with yarn monitoring

A textile machine and yarn technology, which is applied in the field of monitoring the yarn at the workstation of the textile machine, and in the field of yarn monitoring system, can solve the problems of complex electronic devices, high price, and inability to intervene in time, and achieve simple functionality, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

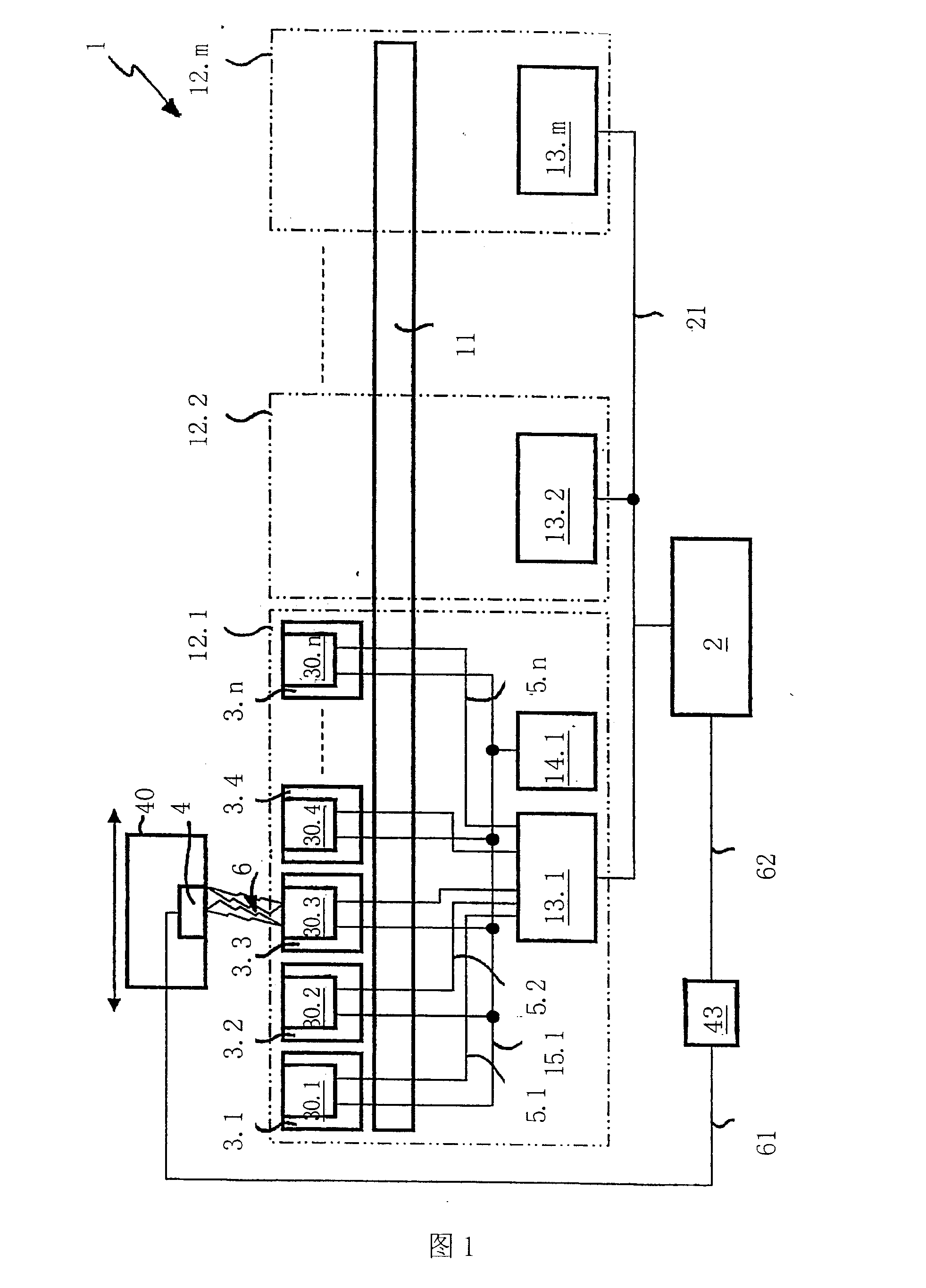

[0029] Figure 1 is a block diagram of various components in a spinning machine 1 according to the underlying invention. The elongated machine frame 11 supports a plurality of spinning units 3.1, 3.2..., 3.n. Modern spinning machines comprise hundreds of such spinning units and these are combined into components 12.1, 12.2..., 12.m every n spinning units. Both m and n are natural numbers, generally m≈16 and n≈20. Unless otherwise indicated, only component 12.1 will be explained in detail below. Of course, these spinning units can also be applied to the special case of m=1, ie a spinning machine without components; and the other parts of the more general case can also be mutated mutatis mutandis. For the sake of simplicity, this figure is only shown schematically in this range, and only the spinning units 3.1, 3.2...m, 3.n are arranged one after the other at one end of the machine frame 11 in this figure. However, under normal circumstances, the spinning unit should preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com