Drying molding technique for twist shaped tea and twist shaped tea firing machine

A forming process and drying machine technology, applied in tea treatment before extraction, etc., can solve the problems of high technical requirements for frying, unstable quality of finished tea, mixed aroma, etc., achieve simple process and equipment structure, and improve external and internal environments , Natural and pure aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

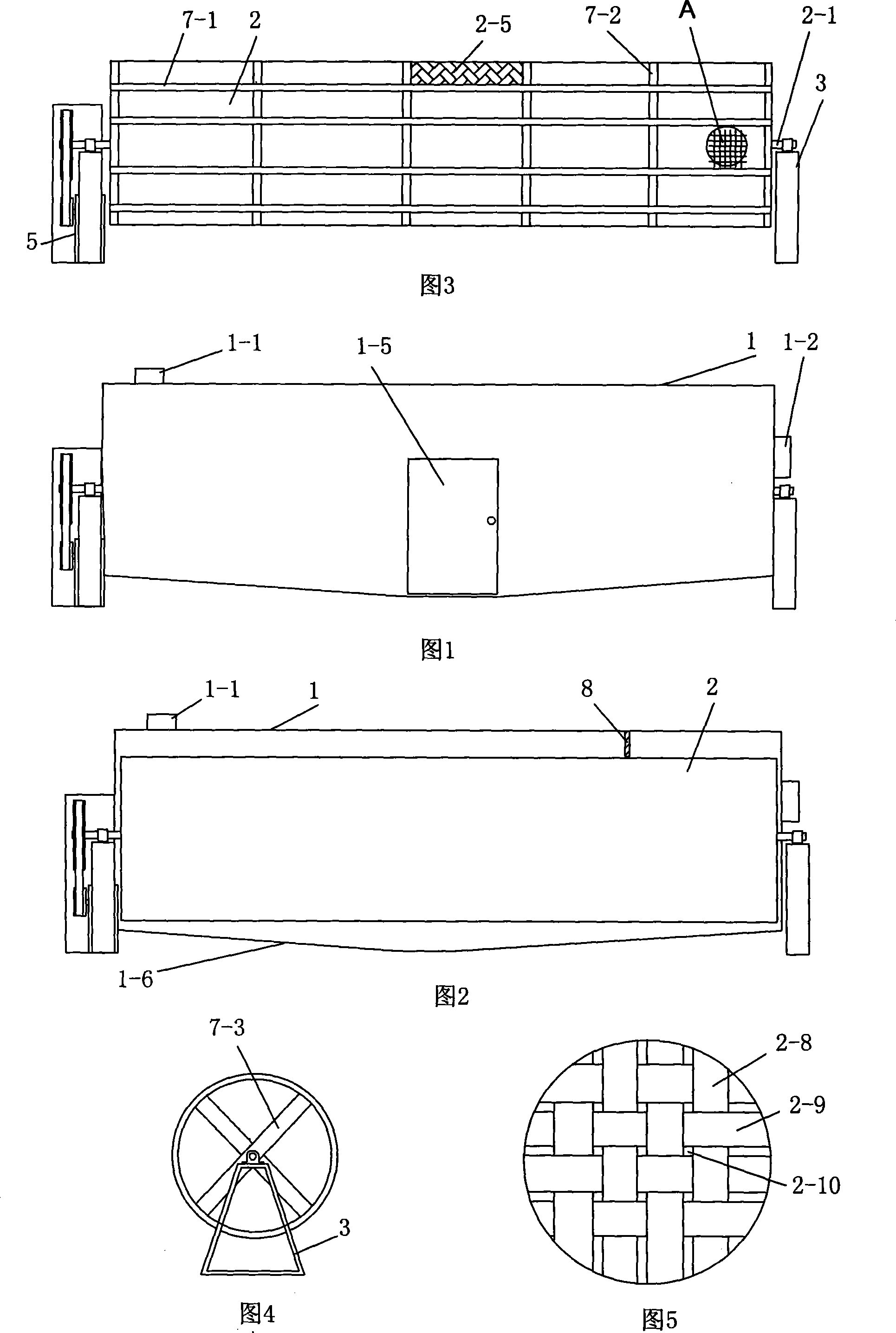

Method used

Image

Examples

Embodiment 1

[0029] Processed Quhao-shaped green tea: 82kg of fresh leaves are processed by a roller de-greening machine, and the temperature is controlled at 260°C. The rotation speed is adjusted to 18r / min, the hot air temperature is 120°C, and the hot air flow rate is 110m 3 / h, the hot air velocity is 6m / s, the whole drying and forming time is 73min, the dry tea is released, spread to cool and then bagged for storage, the measured moisture content of the dry tea is 5.2, and the weight of the dry tea is 18.6kg.

Embodiment 2

[0031] Processing Quhao-shaped green tea: fresh leaves 122kg, after 280 ℃ high-temperature killing, the weight of the killing leaves is 87.kg; the killing leaves are kneaded by a kneading machine for 45 minutes, put into the Quhao forming dryer and tumbled throughout the process; master the speed of the host machine at 22r / min, hot air temperature 110°C, hot air flow 130m 3 / h, the hot air velocity is 9m / s, the whole drying and forming time is 90min, the dry tea is released, spread to cool and then bagged for storage, the measured moisture content of the dry tea is 4.8, and the weight of the dry tea is 29.2kg.

Embodiment 3

[0033] Processing Quhao-shaped green tea: 65kg of fresh leaves, after 260°C high-temperature killing, the weight of the killing leaves is 48.1kg; the killing leaves are kneaded by a kneading machine for 26 minutes, and put into the Quhao forming dryer for the whole process of drying; master the speed of the host machine at 26r / min , hot air temperature 80°C, hot air flow 66m3 / h, the hot air velocity is 3.5m / s, the whole drying and forming time is 96min, the dry tea is released, spread out and stored in bags after cooling, the water content of the dry tea is measured to be 5.5, and the weight of the dry tea is 15.6kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com