Method for producing wind drift sand solidifying polymerization agent

A technology of polymerizing agent and sandstorm, applied in chemical instruments and methods, fertilizer mixtures, organic fertilizers, etc., to achieve the effects of easy popularization of plasticity, cost saving, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

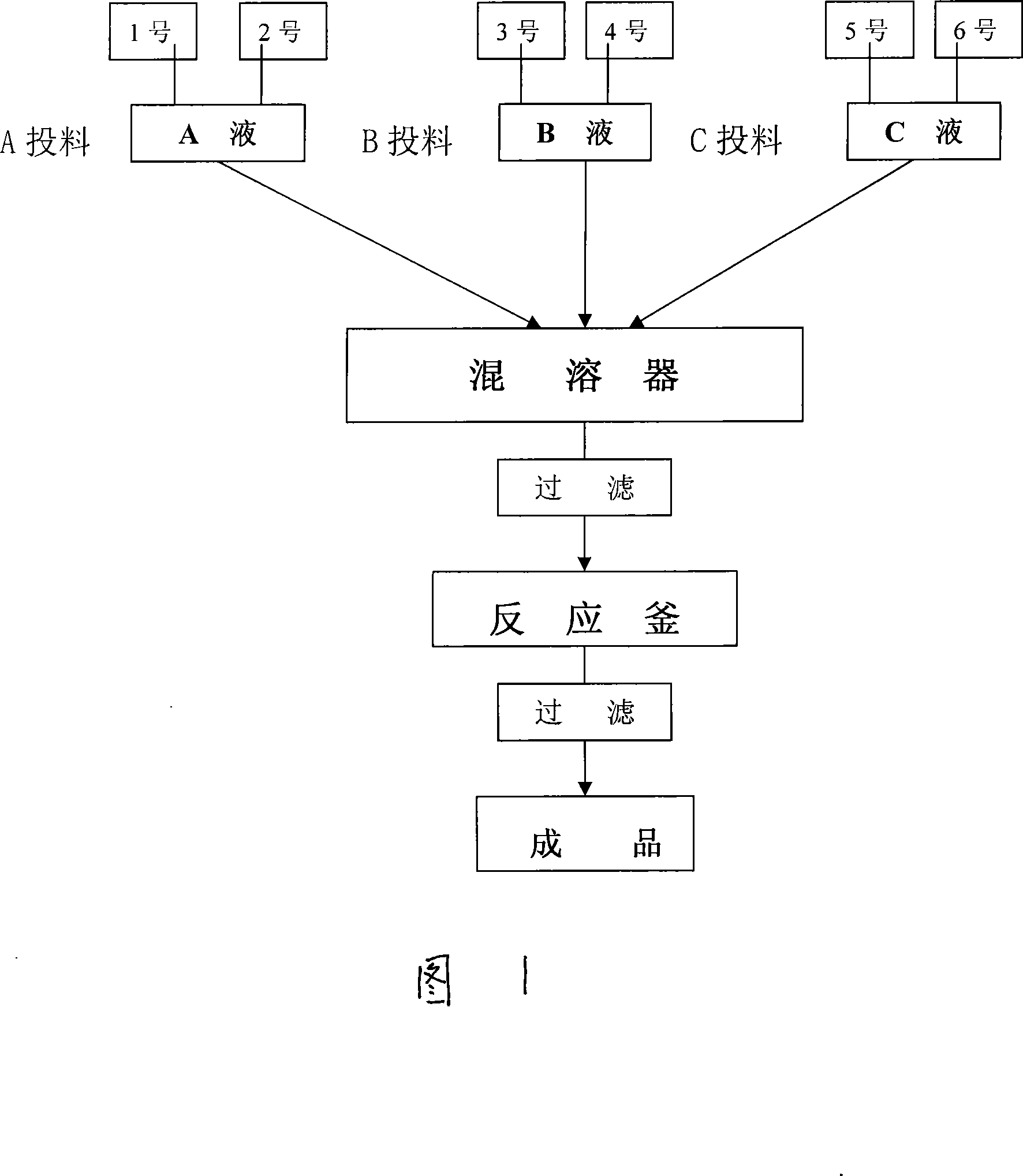

[0012] An example is given below. Calculated based on the preparation of 1000 kg of wind-sand-curing polymerizer. As shown in Figure 1, under normal temperature and pressure, 200 kg of magnesium oxide (No. 1) is dissolved in 500 kg of water (No. 2) to make A liquid; 9 kg of formaldehyde (No. 3) and 240 kg of urea (No. 4) Mix thoroughly to prepare liquid B; fully dissolve 50 kg of acetone (No. 5) and 1 kg of cerium ammonium nitrate (No. 6) to prepare liquid C and age for 5 hours. The three prepared solutions are mixed and then fully stirred to obtain a wind-sand solidified polymerizer. When in use, mix 1000 kg of the aeolian sand curing polymerizer with 3000 kg of aeolian sand and 1000 kg of magnesium chloride, and then add a certain amount of glass fiber filaments (other fiber filaments can also be used), stir evenly, and vibrate to form, that is It can be made into building bricks for different purposes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com