Prefabricated fabric for liquid condition shaping composite material and preparation thereof

A composite material, liquid molding technology, applied in the field of composite material manufacturing, can solve the problems of non-existence and affect the bonding of fiber-matrix interface, and achieve the effect of small impact and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of the toughening layer: Polyethersulfone (PES) was dissolved in tetrahydrofuran (THF) to prepare a 5% solution. On the solution scraping film machine, evenly scrape the PES solution onto the backing paper, and obtain a toughened film after the solvent evaporates. Adjust the height of the knife edge of the scraping film to control the surface density of the toughened film to 20g / m 2 . Trimming and winding to obtain a continuous PES film with a width of about 900mm.

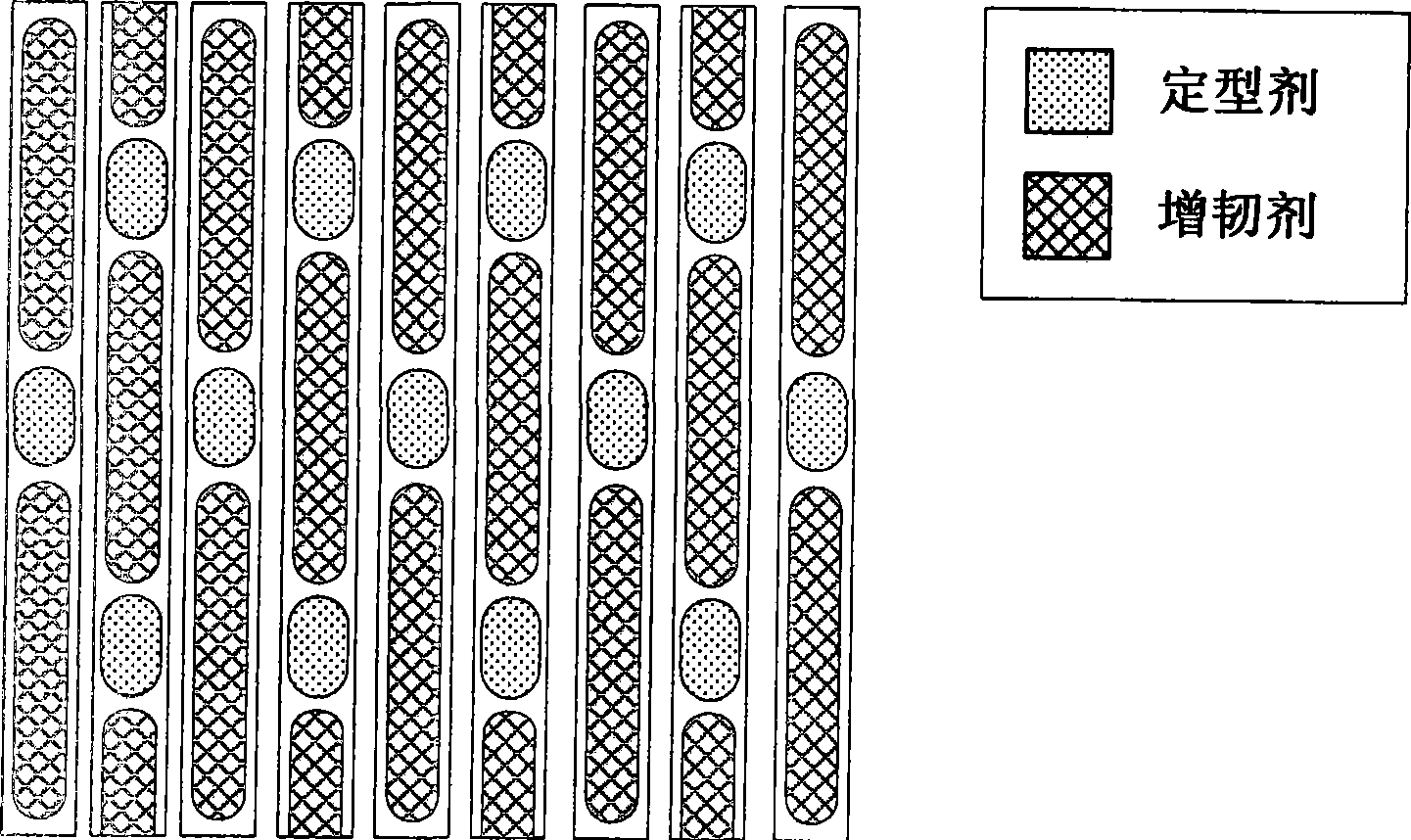

[0037] Place the SW280 plain glass fabric on the stainless steel conveyor belt, and the PES film is unwound and adsorbed on the upper surface of the glass fabric. The fabric covered with PES film moves forward and passes under the THF spraying device. After being dissolved by THF, the PES film closely adheres to the surface of the glass fabric and shrinks as the solvent volatilizes, leaving a gap between adjacent glass strands. out of the gap. After the solvent is volatilized, it is wound up...

Embodiment 2

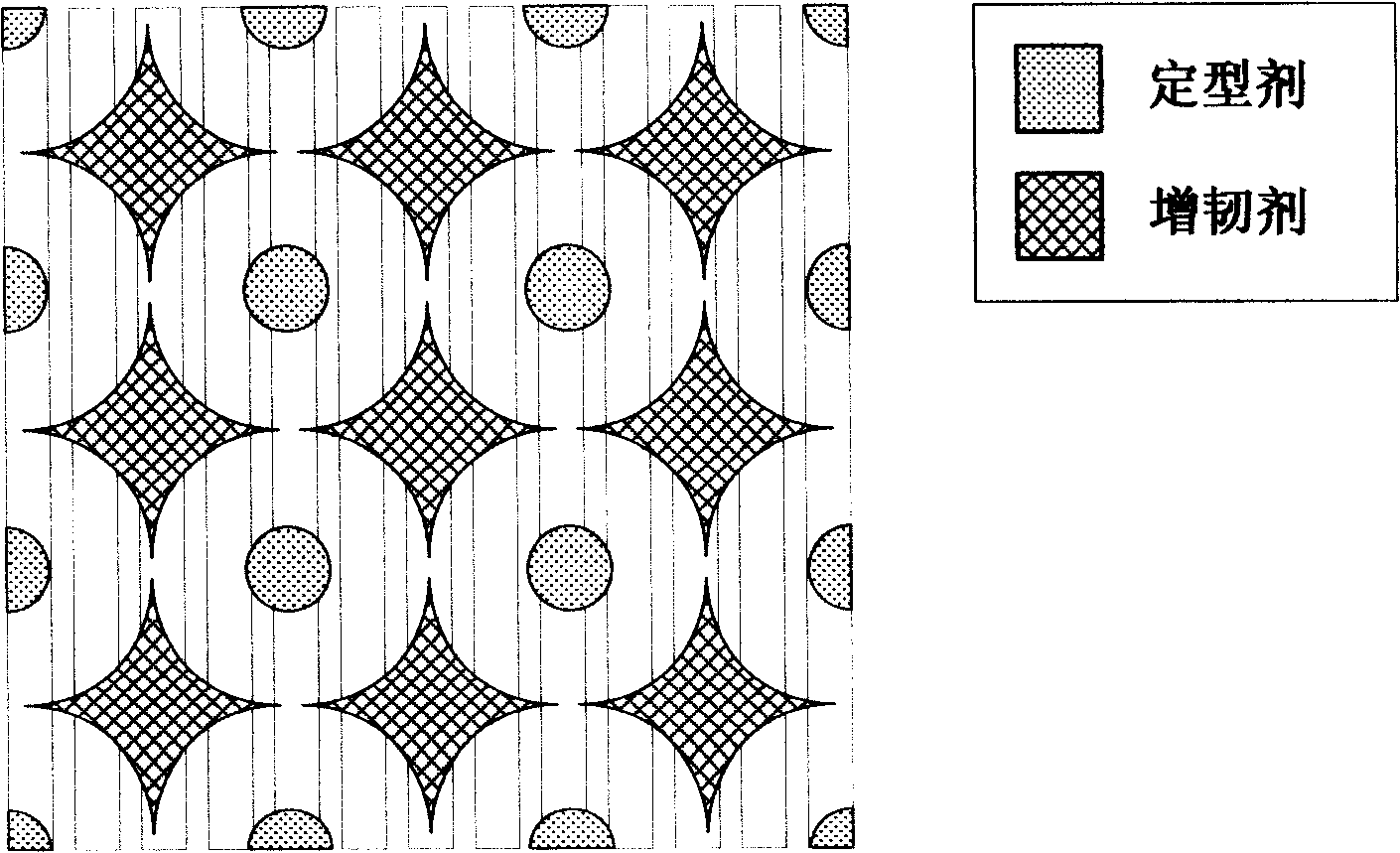

[0041] Preparation of toughening layer: Add polyetherimide (PEI) resin powder into water dissolved with emulsifier and thickener to prepare a slurry with a viscosity of about 10 000 cPoise and a solid content of about 35%. The slurry is coated on the G827 unidirectional carbon fiber fabric through a rotary screen engraved with a specified pattern on the slurry point coating machine, and passed through a high-temperature oven at 380 ° C to melt and bond the PEI powder on the surface of the carbon fiber fabric. By designing the pattern of the rotary screen, the surface density of the sizing agent is controlled to 10g / m 2 . So far, the compounding of the toughening layer is completed. (A typical toughening layer pattern is shown in Figure 3).

[0042] Preparation of the shaping layer: carboxy-terminated nitrile rubber (CTBN) particles and AG80 epoxy resin were mixed in a weight ratio of 5:100, and then cryogenically frozen and pulverized to make shaping agent particles. On the...

Embodiment 3

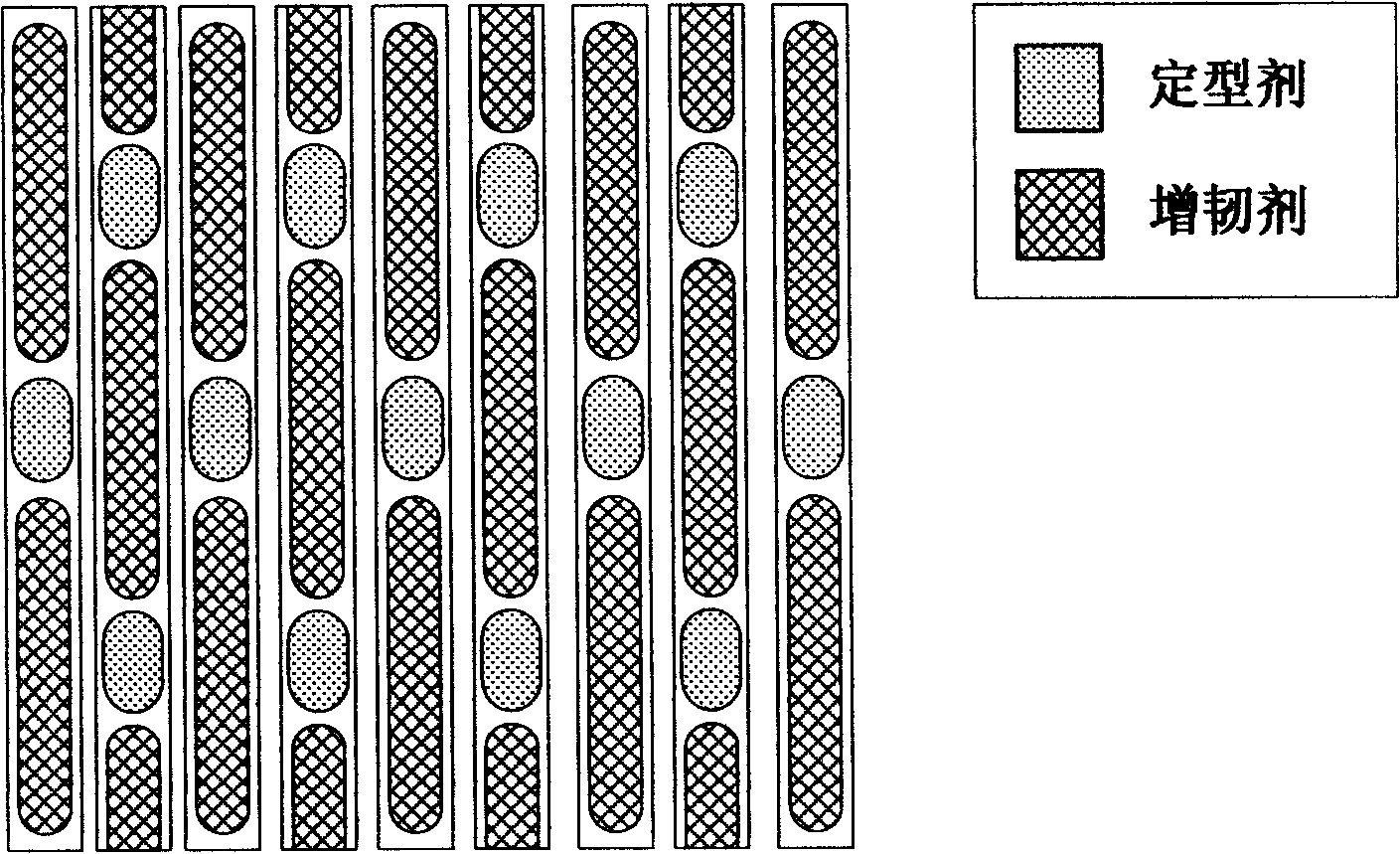

[0045] Preparation of toughening-setting dual-functional layer: polyaryletherketone (PAEK) resin was dissolved in tetrahydrofuran (THF) to prepare a 20% solution. Print this solution onto G827 unidirectional carbon fiber fabric on a gravure printing machine to form a specified pattern, and control the surface density to 15g / m by designing the groove depth and pattern 2 . Before the solvent volatilizes and PAEK is still in a solution state, the fabric is passed through a vibrating screen, and CTBN / AG80 sizing agent particles are quantitatively sprinkled on the surface of the fabric. After the solvent evaporates, the sizing agent particles attached to the exposed fiber surface are sucked away by the air funnel, while the sizing agent particles attached to the surface of the toughening agent droplet are bonded to the fabric by PAEK. Select the mesh size and feed speed, and control the areal density of the sizing agent to be 6% of the areal density of the G827 unidirectional carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com