Manufacture of surface decoration film, construction method and application of the same

A technology of surface decoration and film laying, applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of large thickness and high production cost, achieve good anti-permeability, solve pollution and a large amount of waste, and have high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

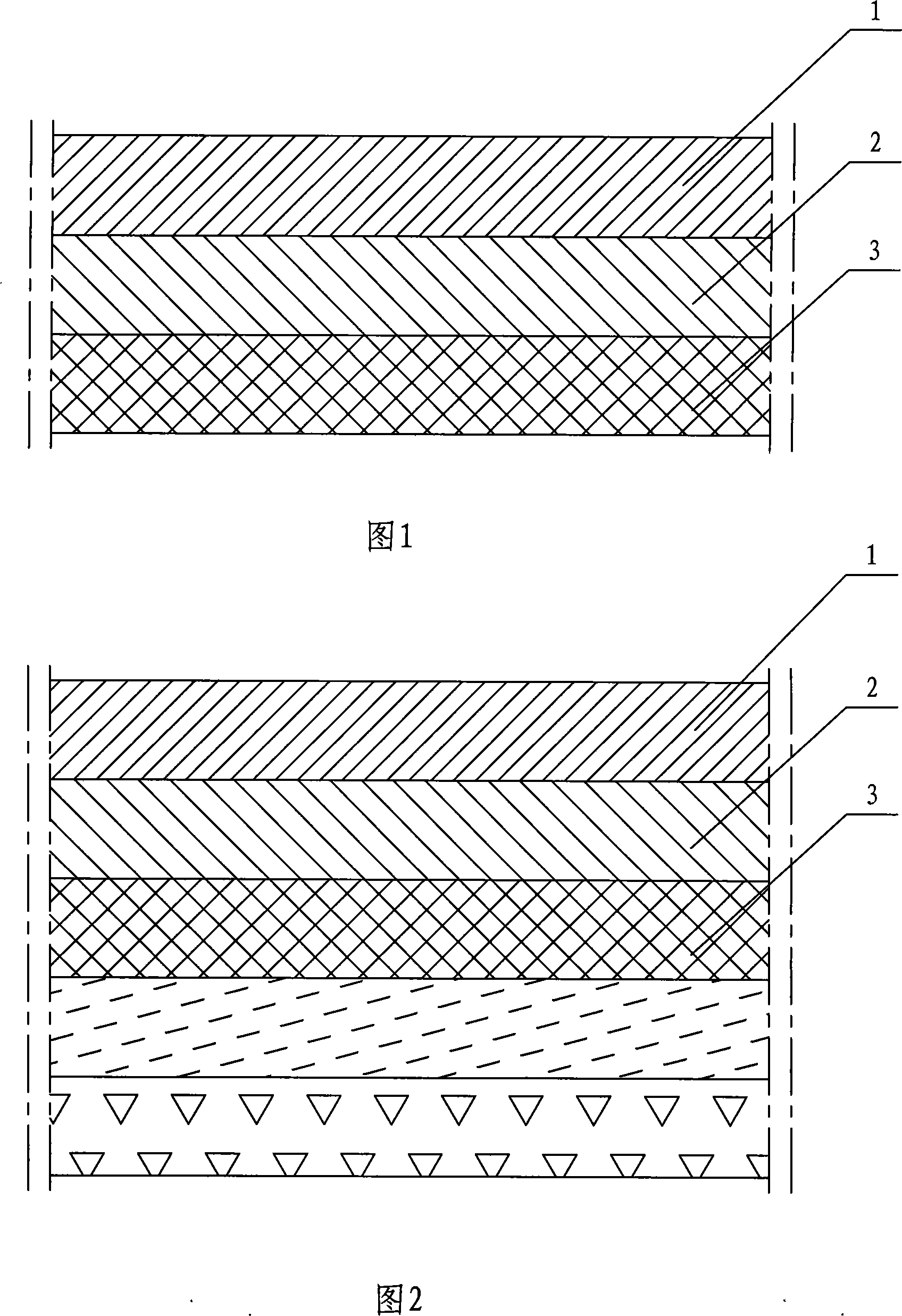

[0024] Referring to Fig. 1, a kind of surface decoration film, it is three layers, is protective layer 1, paint layer 2 or dry powder layer successively from top to bottom, and PET composite film layer 3. Wherein, the paint layer is a fluorocarbon paint layer or a baking paint layer, the paint layer or dry powder layer has a thickness of 0.025-0.035 mm, and the PET composite film layer has a thickness of 0.2 mm-0.5 mm.

[0025] During production, the roll-shaped PET composite film layer 3 is first placed on the conveyor belt, one end of which is pulled forward by the traction mechanism, and fluorocarbon paint, baking varnish or dry powder is sprayed on the surface of the PET composite film layer, and then dried. A fluorocarbon paint layer, baking varnish layer or dry powder layer with a thickness of 0.025mm-0.035mm is formed on the surface of the PET composite film layer, and then coded on the back of the PET composite film layer. The coded content includes model, batch and len...

no. 2 example

[0029] Referring to FIG. 2 , an adhesive layer 4 and a lower protective layer 5 are sequentially arranged under the PET composite film layer 3 .

[0030] During production, a strong adhesive layer 4 is sprayed on the back of the PET composite film layer, a lower protective layer 5 is laid on the surface of the adhesive layer, and the back surface of the lower protective layer is coded. The coded content includes model, batch and length, and finally rolled into shape.

[0031] During construction, remove the lower protective layer from the surface decorative film with the adhesive layer, and then directly lay it on the metal, wooden or plaster components, and then use a roller or an iron to press and stick it firmly.

[0032] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com