Main mirror face deformation detecting method and system for space reflection type optical remote sensor

A technology of optical remote sensor and detection system, which is applied in the direction of testing optical performance, etc., can solve the problems of prolonged detection time, heavy weight, not very suitable for space optical remote sensor, etc., and achieve the effect of strong concealment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

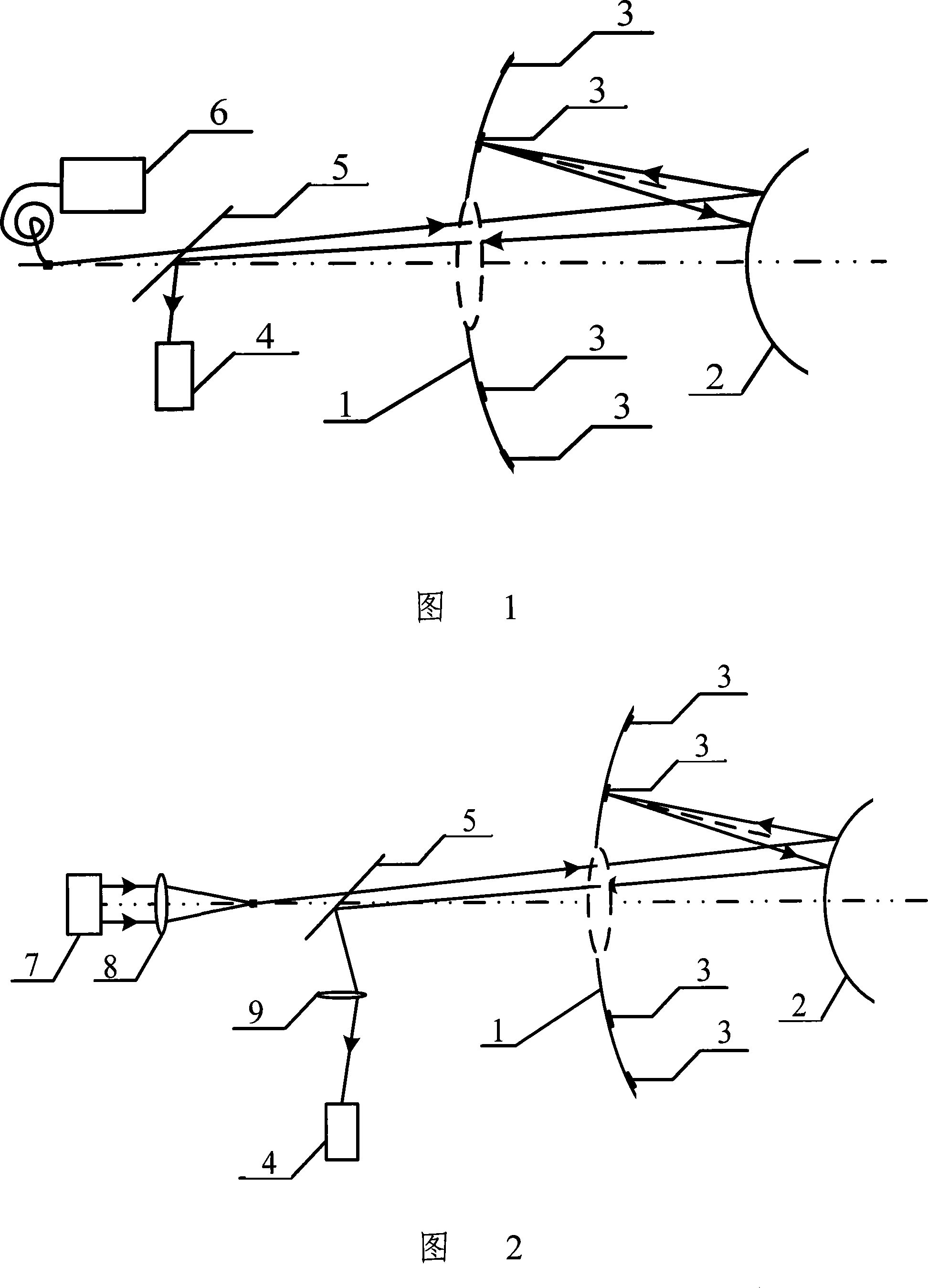

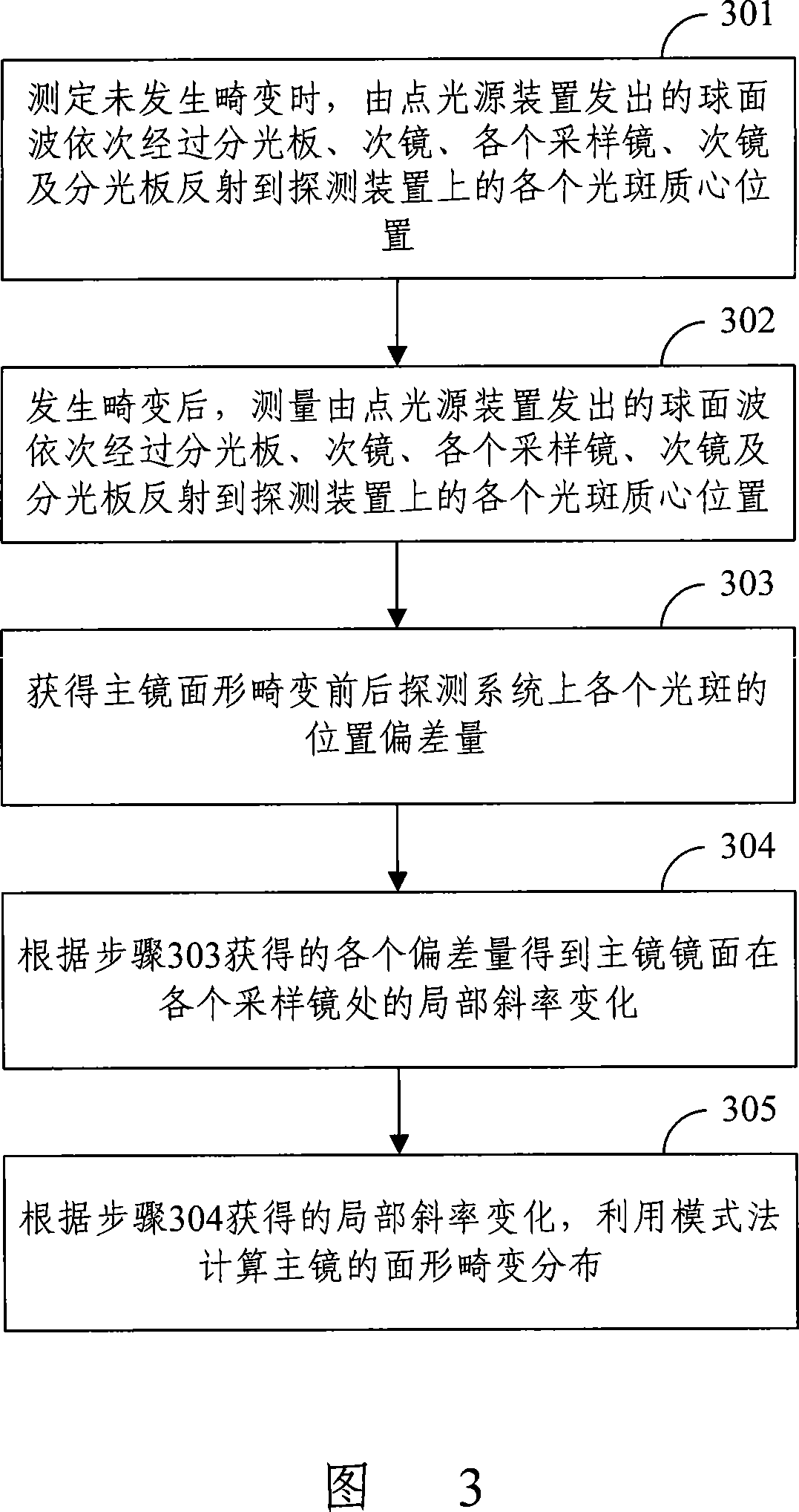

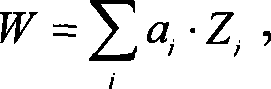

[0035] Below in conjunction with accompanying drawing, concrete implementation of the present invention is described in further detail:

[0036]The basic idea of the present invention is: a point light source device is set inside the spatial reflective optical remote sensor as a beacon, and fixed on or near the main mirror surface of the spatial reflective optical remote sensor according to the requirements of measurement accuracy and the requirements of the Nyquist sampling theorem. Multiple sampling mirrors, at the same time fix the secondary mirror in front of the main mirror of the spatial reflective optical remote sensor, fix the beam splitter and the detection device between the point light source device and the primary mirror, and arrange the positions of each device so that the primary mirror is in normal Under normal circumstances and when distortion occurs, the point light source device can be detected by the detection device through the reflection of the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com