On-line three-dimensional temperature field D/A system of step type bar plate heating stove

A three-dimensional temperature, slab heating technology, applied in the direction of comprehensive factory control, electrical testing/monitoring, comprehensive factory control, etc., can solve problems such as difficult temperature distribution, and achieve the effect of reducing energy consumption, optimizing heating system, and improving heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

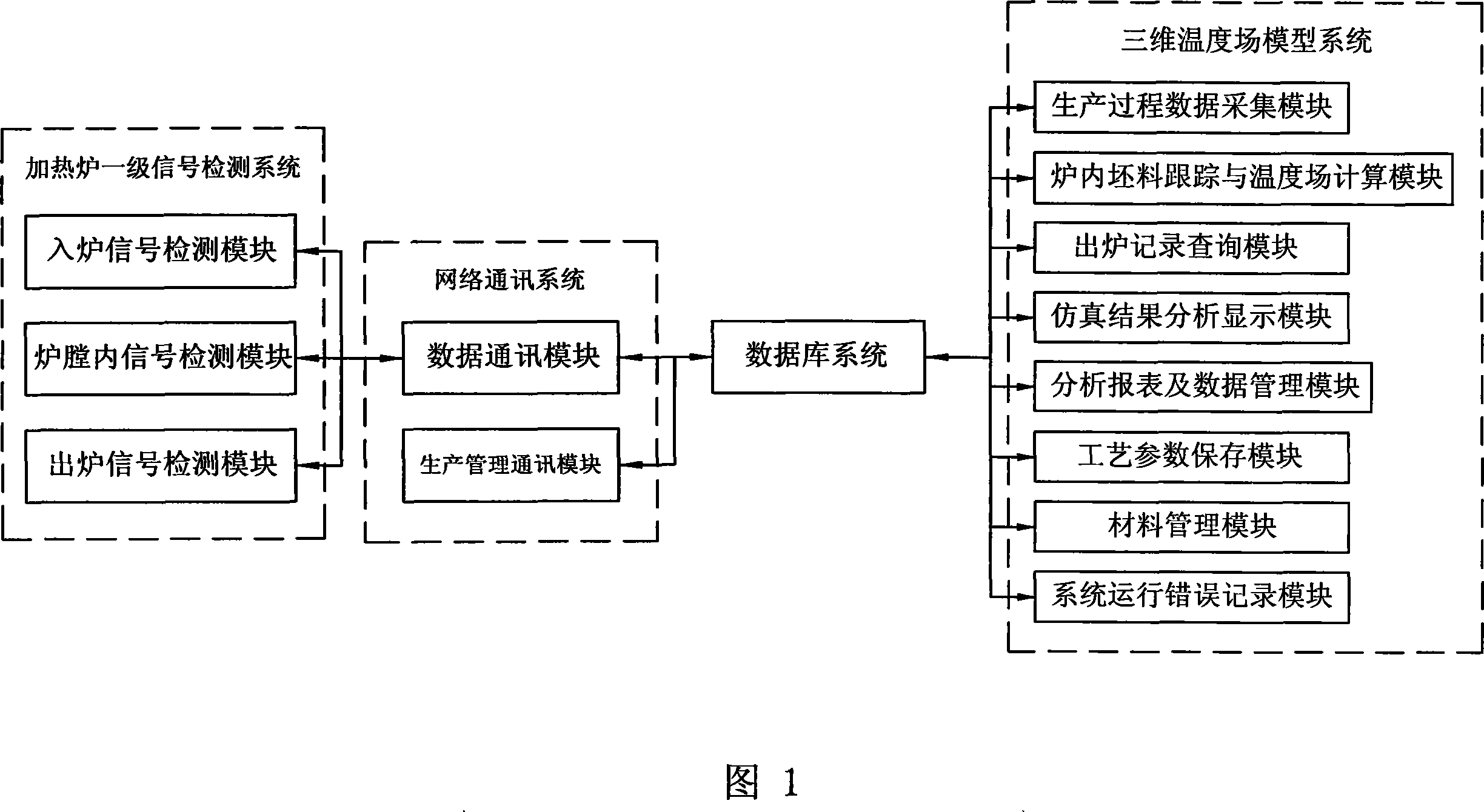

[0031] As shown in Figure 1, an online three-dimensional temperature field digital modeling system for a walking slab heating furnace is composed of a heating furnace primary signal detection system, a network communication system, a database system, and a three-dimensional temperature field model system, in which:

[0032] The first-level signal detection system of the heating furnace is used for real-time data detection of the billet in the furnace, furnace and furnace, and the detection data is transmitted to the first-level system;

[0033] The network communication system is used to connect with the first-level system and the management network system to transfer real-time data and production management information data into the system database;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com