Method of diagnosis of varying load mechanical failure

A technology of mechanical faults and diagnostic methods, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as complex, easy to misdiagnose, and difficult to apply calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

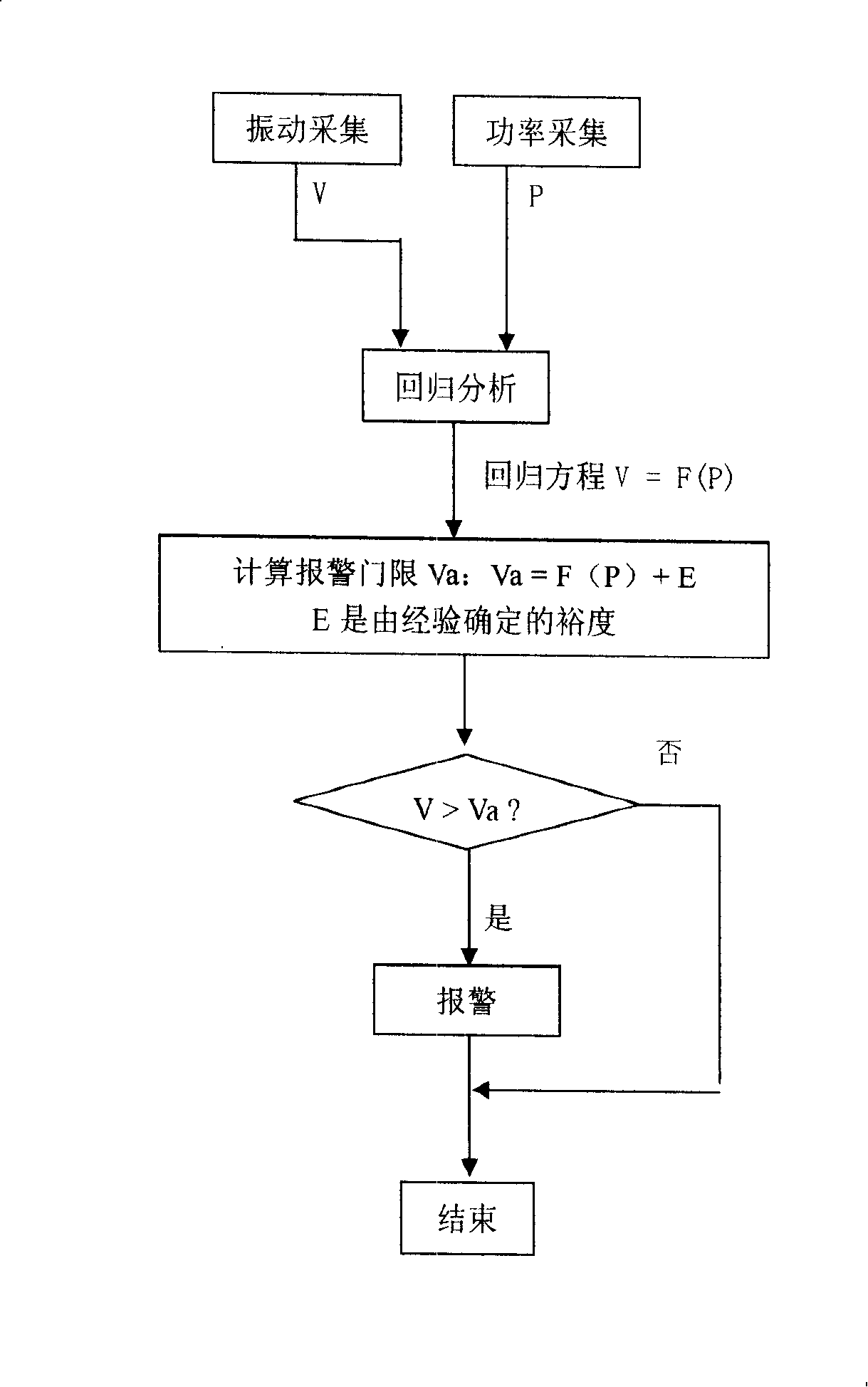

[0007] The vibration signal of the machine is collected by the vibration sensor, and the power signal of the machine is collected by the power transmitter. After conditioning and analog / digital conversion, the signal is input to the on-site data acquisition equipment, and transmitted to the server through the data communication equipment, and the data is analyzed and stored online through the software on the server. The fault diagnosis system can monitor multiple machines at the same time, and can also publish information to the Internet through the server. Authorized users can view real-time data and diagnose and analyze as long as they log in to the server.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com