Cookware suitable for induction cooker and manufacturing method thereof

A manufacturing method and technology of induction cooker, which can be applied to home appliances, kitchen appliances, applications, etc., can solve problems such as falling off and separation, and achieve the effect of cost control and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the structure, characteristics and achieved effects of the present invention in detail, the following preferred embodiments are given below and described with reference to the accompanying drawings.

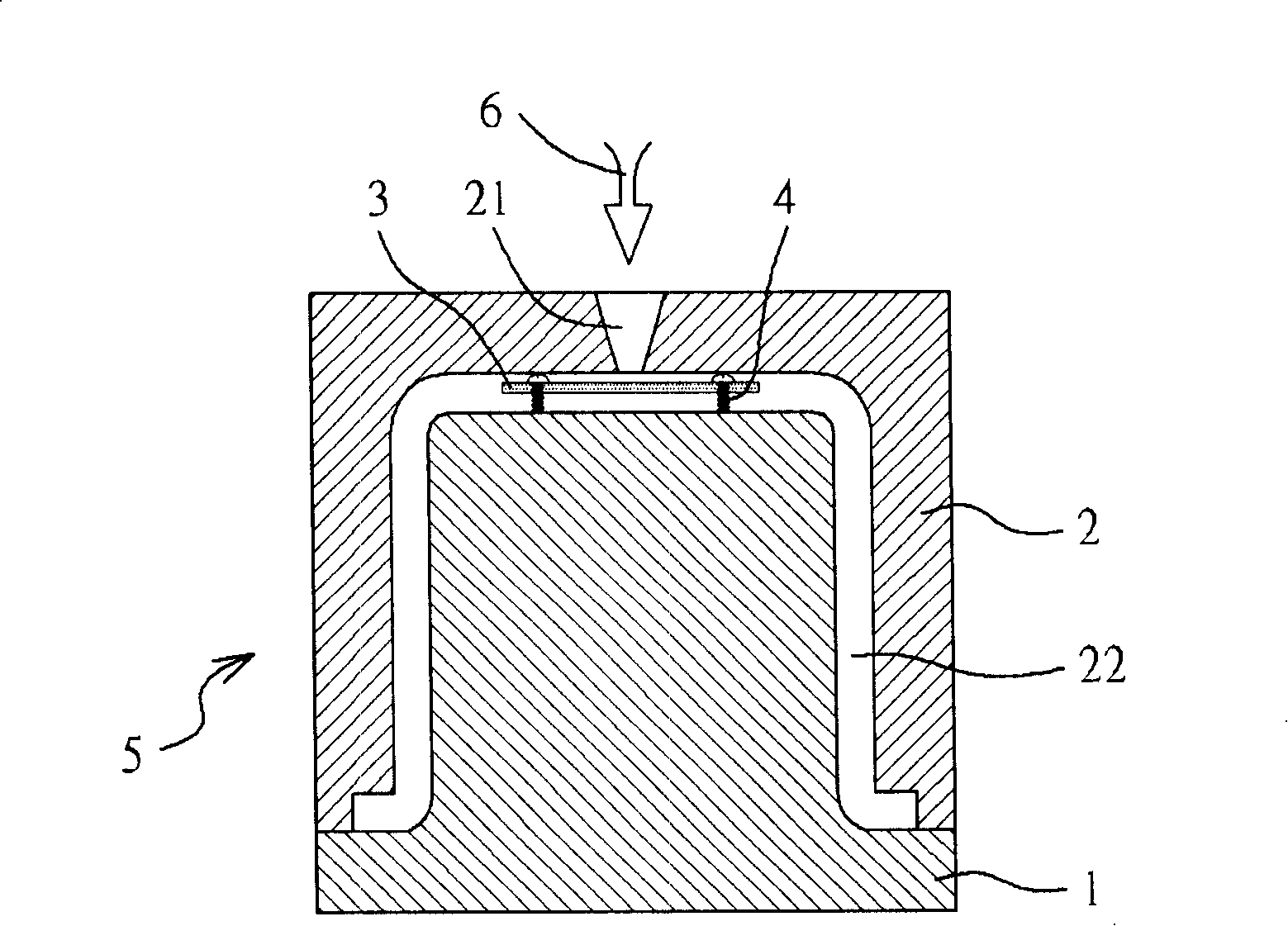

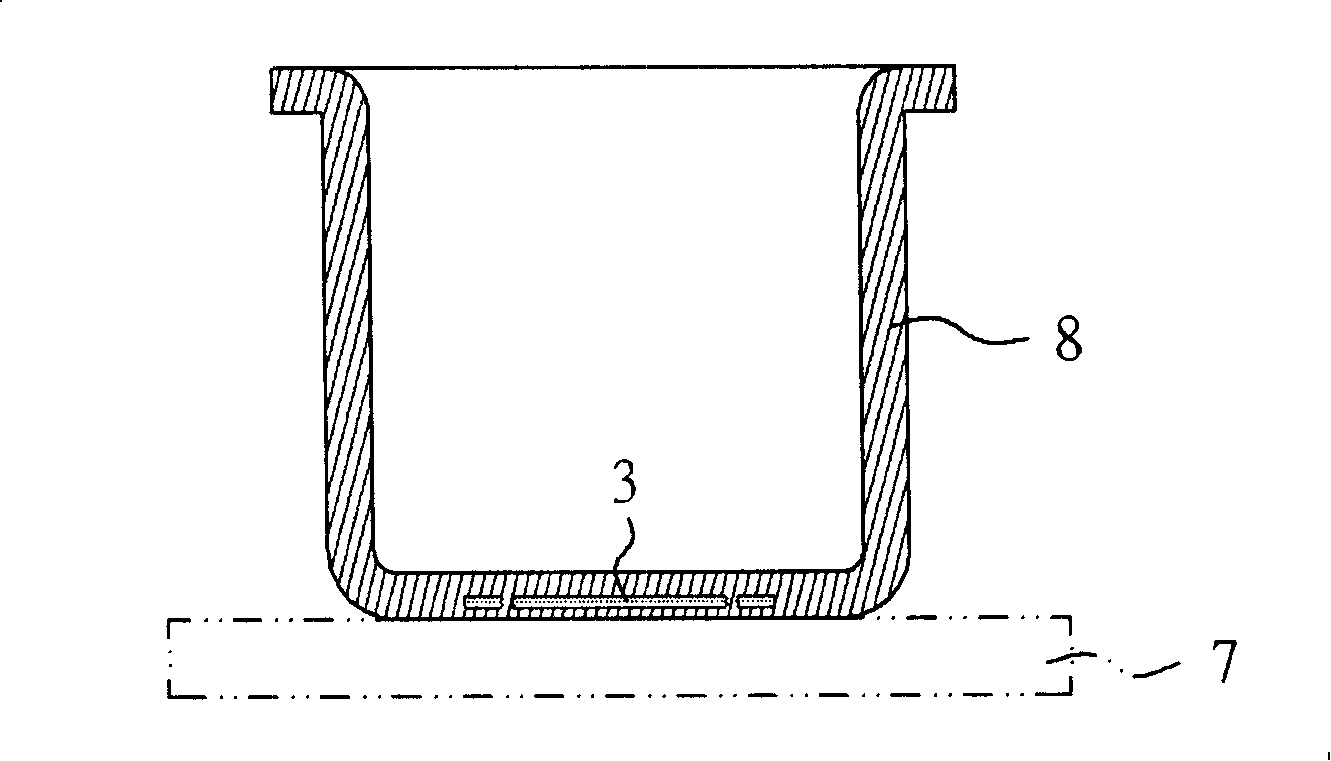

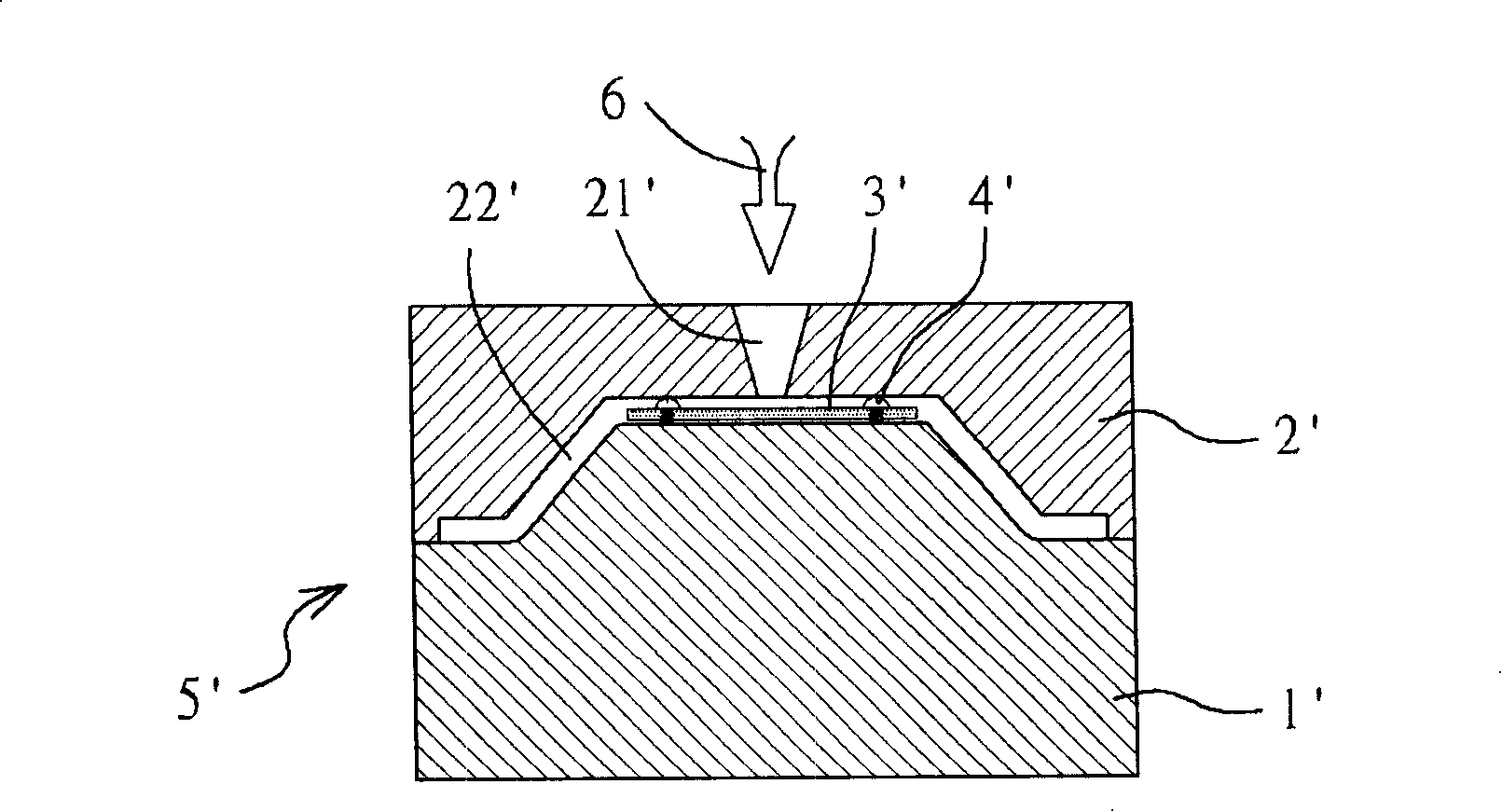

[0030] The pan applicable to the induction cooker provided by the present invention and its manufacture method, such as figure 1 , image 3 As shown, it is mainly composed of a fixed mold base 1, 1', a movable mold base 2, 2', a magnetic medium 3, 3', and several screws 4, 4' in a preset form. Mold 5, 5'.

[0031] During processing, first lock a piece of magnetically conductive medium 3, 3' to only screws 4, 4' of the same material as the cooker, and set it across the top surface of the fixed mold base 1, 1', and then , combined with the corresponding movable mold bases 2, 2', after the mold closing is completed, the metal liquid 6 of the non-magnetic material with a low melting point is injected into the mutually closed mold cavities 22, 22' from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com