Apparatus for controlling engine fuel quantity

A control device and fuel control technology, applied in the direction of engine control, fuel injection control, machine/engine, etc., can solve the problems of unable to stop, the stepping motor can not be controlled accurately without returning to the position, and the cost can be achieved. Low, conducive to mass production promotion, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

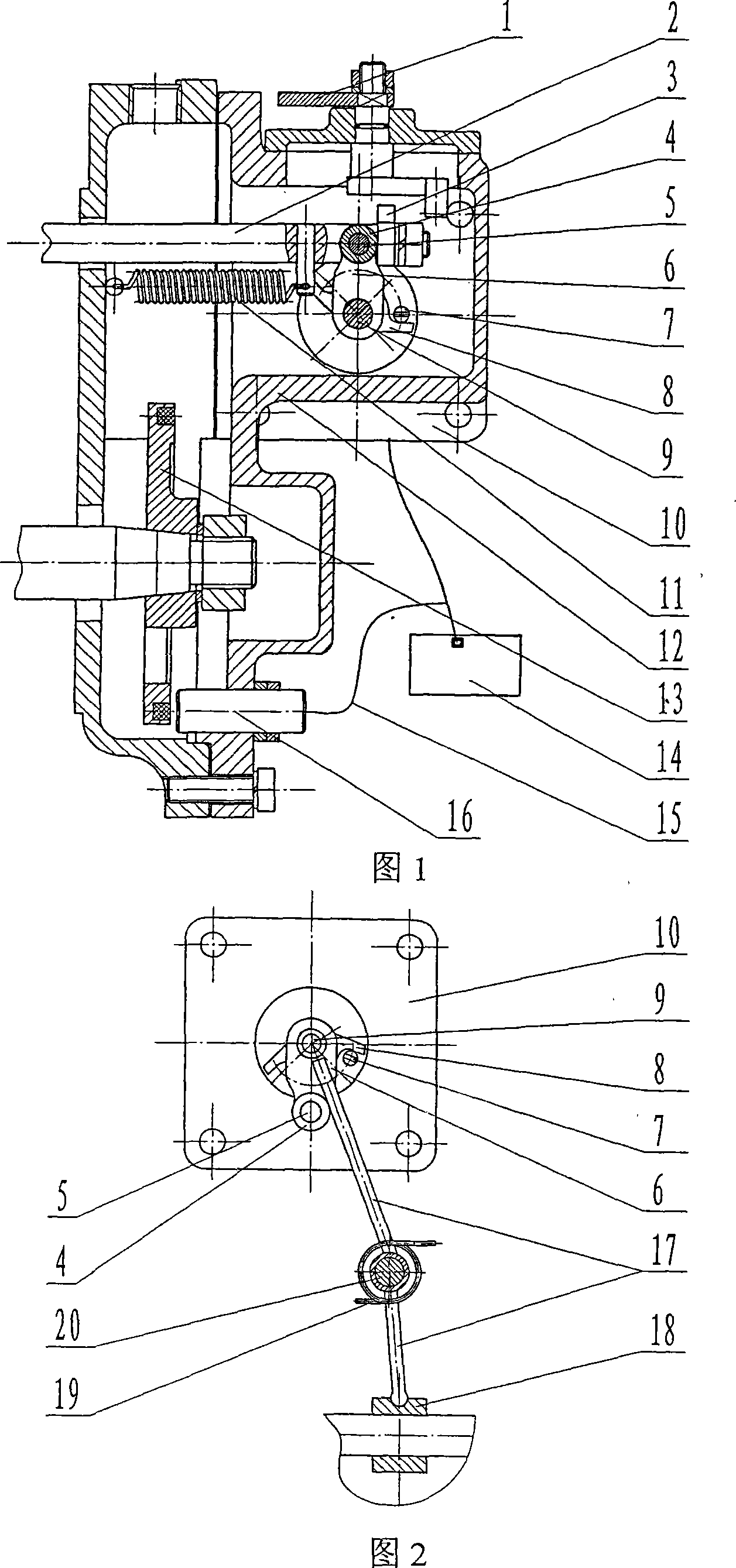

Embodiment 1

[0028] figure 1Shown is the engine fuel quantity control device using the in-line pump rack 2 as the engine fuel quantity control mechanism. The engine fuel quantity control device also includes an oil stop handle 1 and a rear cover 12; the connecting device is mainly composed of a stopper 3, a roller 4, a roller pin 5, a rocker arm 6, a positioning screw 7, a positioning baffle 8 and a return spring 11, The block 3 is connected with the in-line pump rack 2, the roller pin 5 is connected with one end of the rocker arm 6, the roller 4 is set outside the roller pin 5, the positioning baffle 8 is fixed with the other end of the rocker arm 6, and connected to the output of the stepping motor. On the shaft 9, one end of the return spring 11 is fixed, and the other end is connected with the positioning baffle 8 and the in-line pump rack 2. The controller 14 determines the working condition of the current engine according to the input of the sensor 16 and other switches, determines ...

Embodiment 2

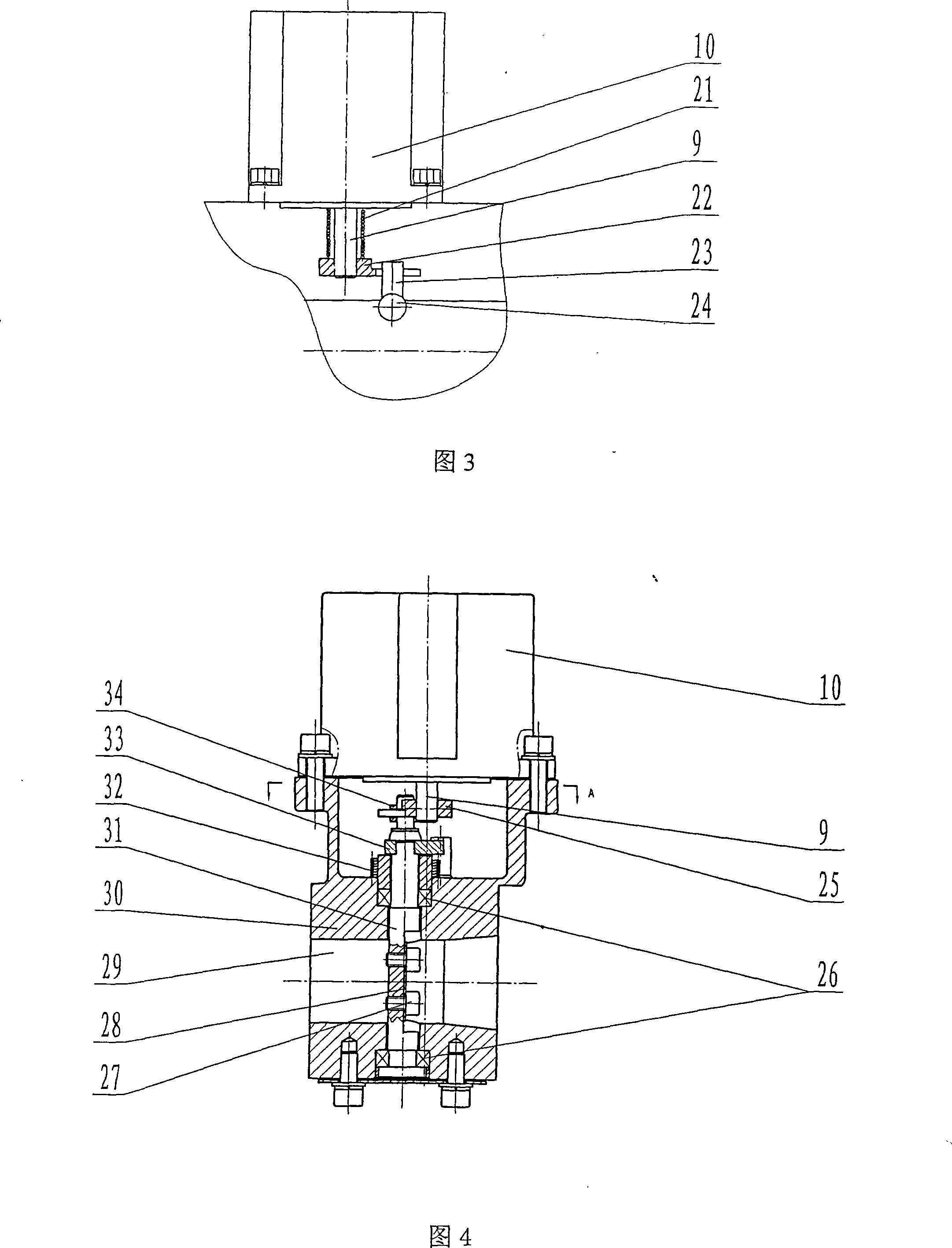

[0034] figure 2 A schematic diagram of the engine fuel quantity control device using the distribution pump control sliding sleeve 18 as the engine fuel quantity control mechanism is shown. The connection device is mainly composed of roller 4, roller pin 5, rocker arm 6, positioning screw 7, positioning baffle 8, lever 17, torsion spring 19 and torsion spring pin 20. The roller pin 5 is connected with one end of the rocker arm 6, and the roller 4 Set on the outside of the roller pin 5, the positioning baffle 8 is fixed with the other end of the rocking arm 6, connected on the output shaft 9 of the stepper motor, the lever 17 is fixed with the torsion spring 19, and the torsion spring 19 is sleeved on the torsion spring pin 20.

[0035] The position shown in the figure is the initial position in the power-off state: the torsion spring 19 sleeved on the torsion spring pin 20 applies a torque to the lever 17 in the counterclockwise direction as shown in the figure through the pre...

Embodiment 3

[0040] image 3 A schematic diagram of the engine fuel quantity control device using the single cylinder pump rack 24 of the diesel engine as the engine fuel quantity control mechanism is shown. Connecting device mainly is made up of torsion spring 21, rocking arm 22, stopper 23, and torsion spring 21 one end is fixed, and the other end links to each other with rocking arm 22, and rocking arm (22) is connected on the stepper motor output shaft (9), and stopper 23 links to each other with diesel single-cylinder pump rack 24.

[0041] When the controller 14 is not powered on, the stepper motor 10 loses power, or the controller 14 cuts off the current of the stepper motor 10, under the action of the pretightening force of the torsion spring 21, the output shaft 9 of the stepper motor, the rocker arm 22, the gear Block 23 and diesel engine single-cylinder pump rack 24 will be located in the initial position under the location of set screw and locating baffle plate. This initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com