Real time monitoring system for hydrogenation reaction effluent cooling process

A technology for hydrogenation reaction and cooling process, applied in the field of detection systems, can solve problems such as economic loss, poor operability, erosion of REAC systems, etc., to improve accuracy and reliability, avoid unplanned shutdowns, and overcome limitations. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

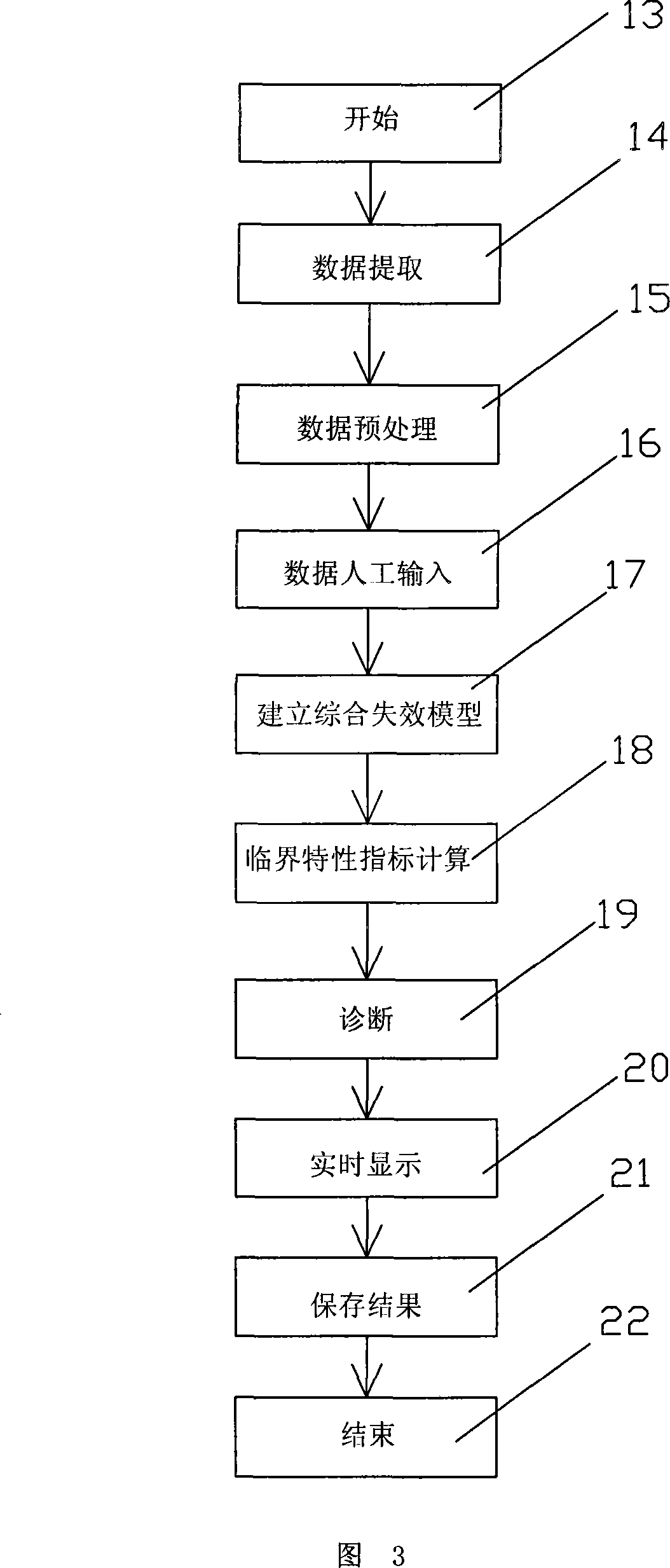

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

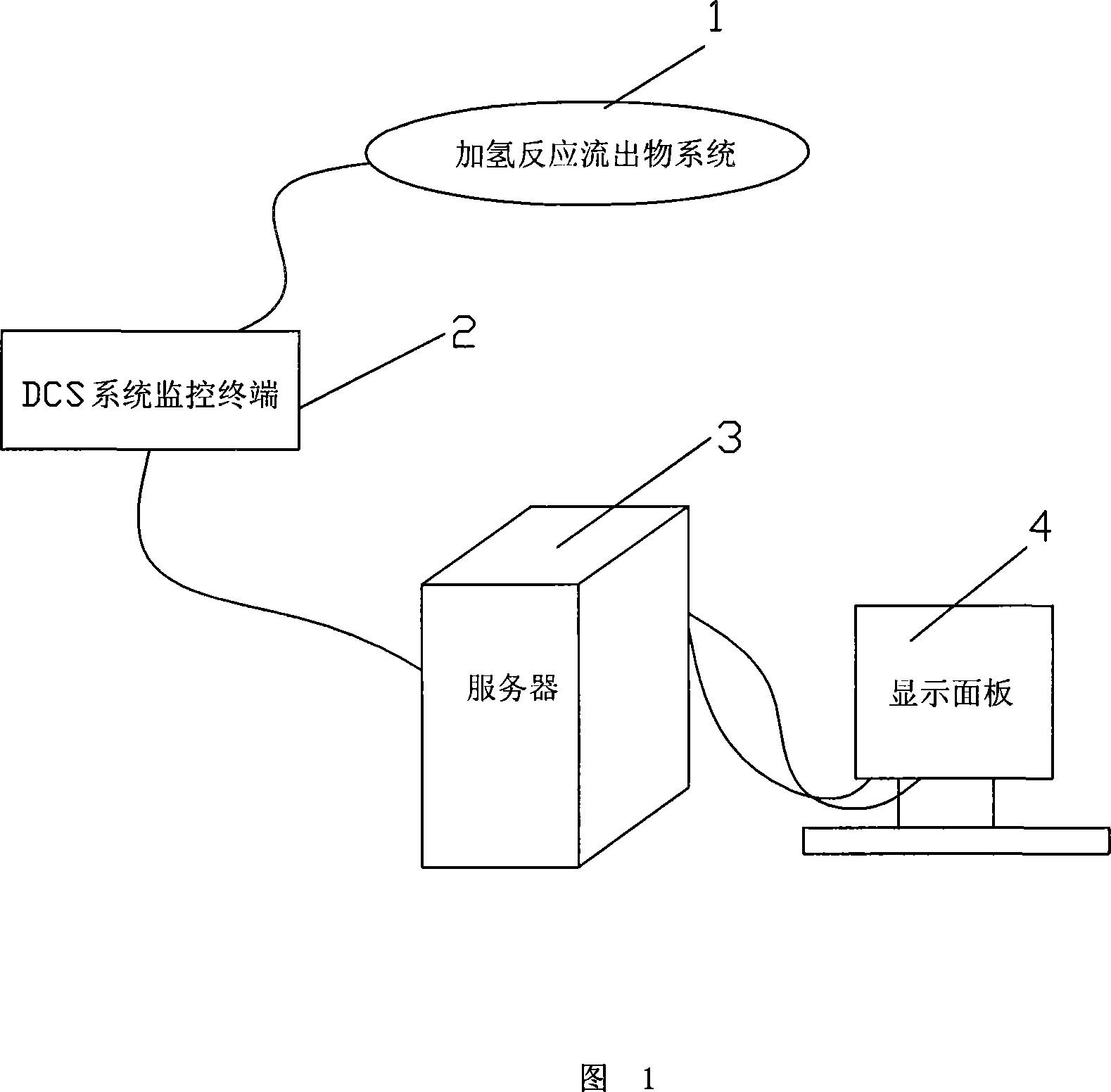

[0024] As shown in Figure 1, the sensors installed on the on-site hydrogenation reaction effluent system 1 perform preprocessing such as filtering, buffering, conditioning, and amplification according to different signals, and then transmit them to the corresponding data acquisition and DCS system through the data line The monitoring terminal 2 and the server 3 extract operating parameters from the DCS control system through data lines and store them in the local database; the diagnosis results of the server 3 display the failure control parameters of the current hydrogenation reaction effluent system through the display panel 4 .

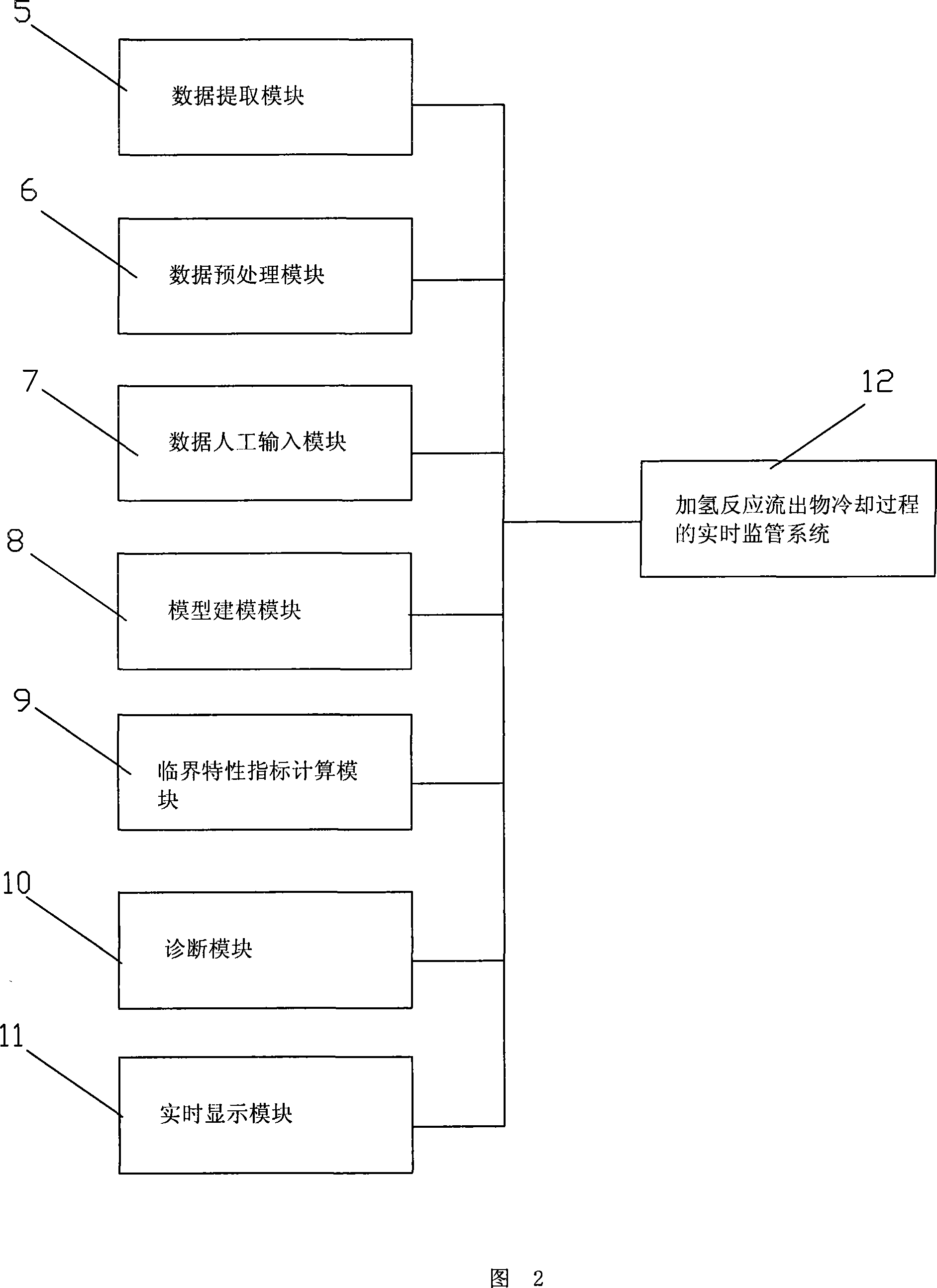

[0025] As shown in Figure 2, the server 3 is the real-time monitoring system 12 of the hydrogenation reaction effluent cooling process, using a computer and system development tools, the system development tools are compiled with VisualC++...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com