Vacuum low temperature microscopic visualizer

A vacuum low temperature, observer technology, applied in the field of microscopic observer, to avoid the effect of natural loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

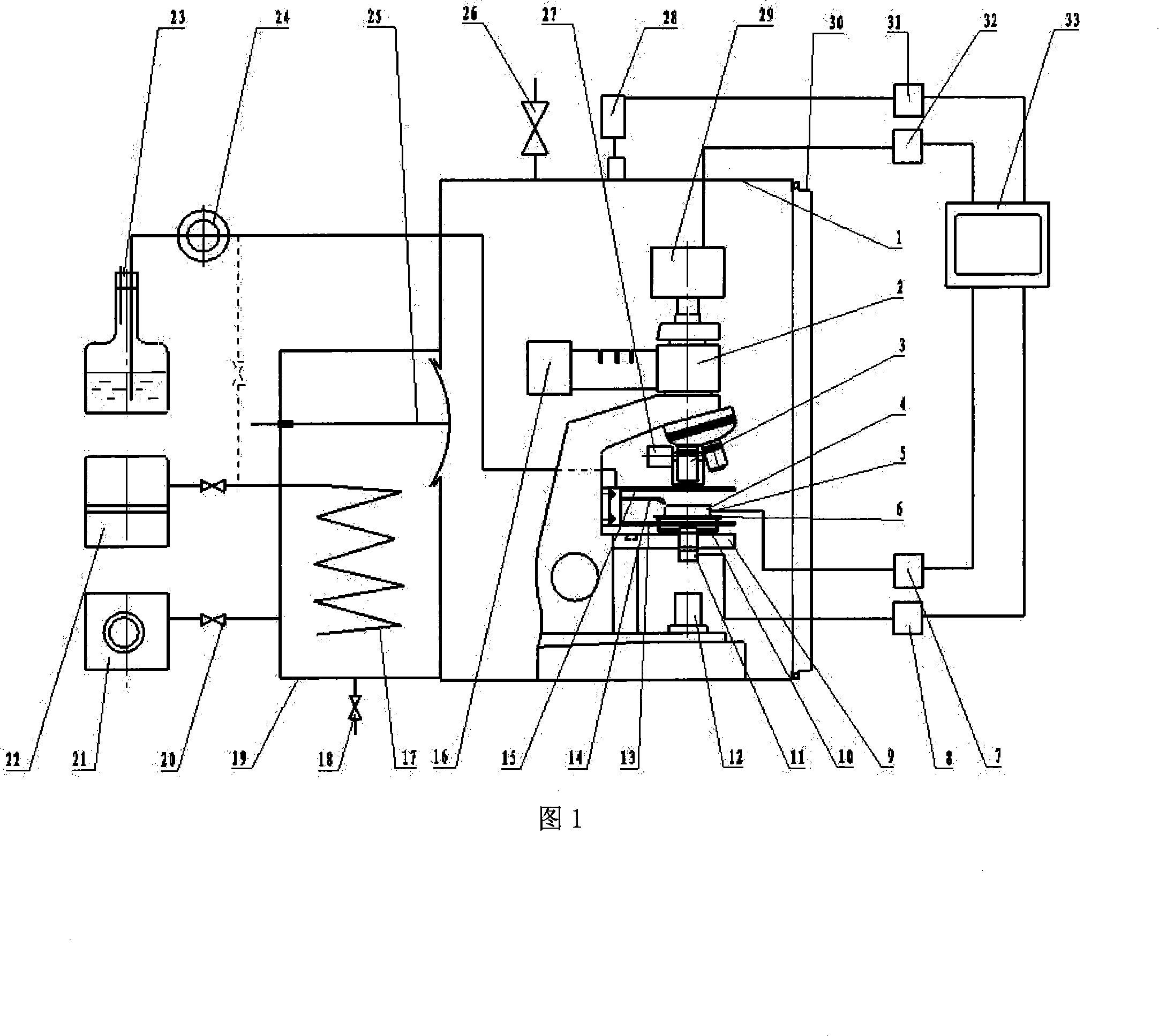

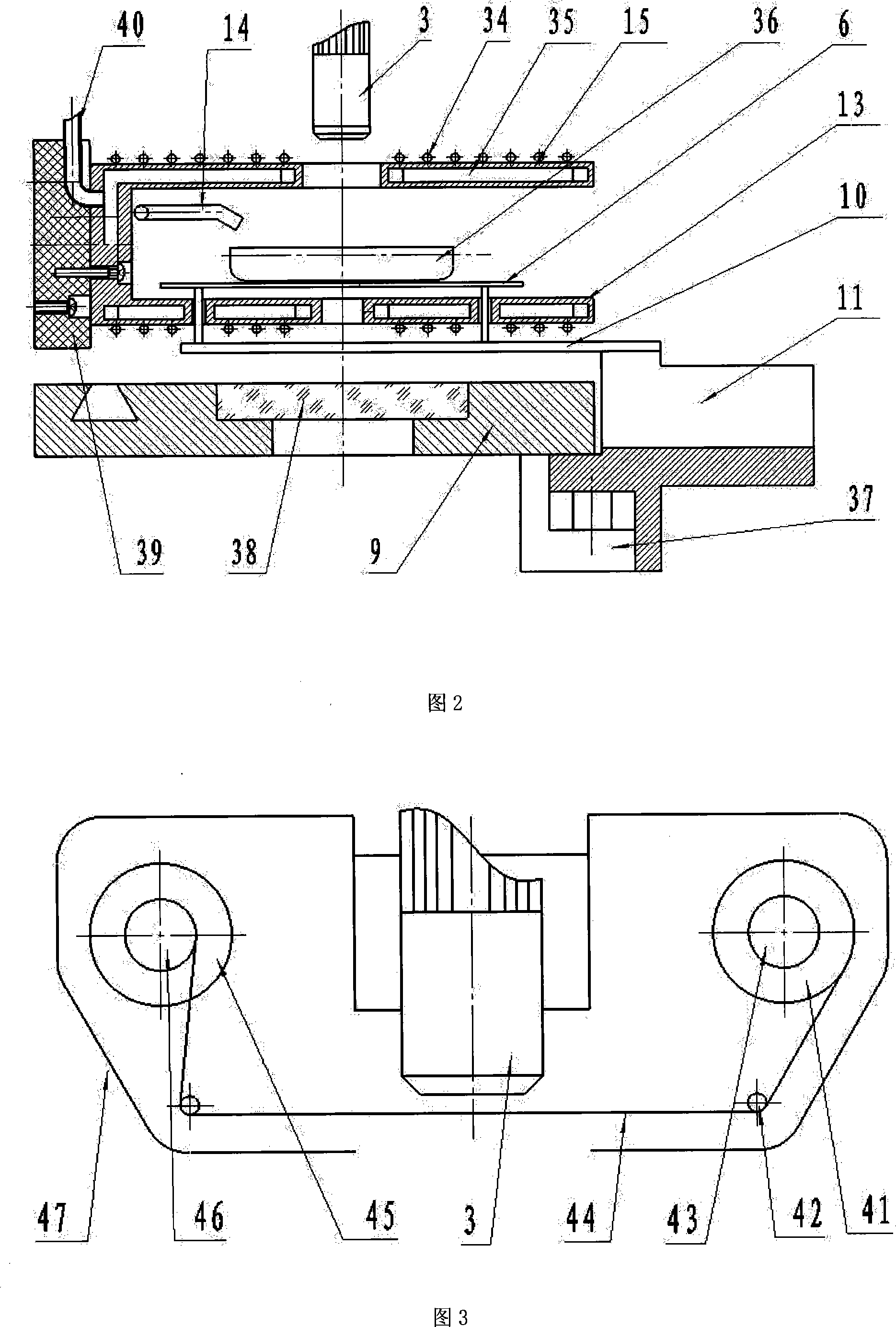

[0025] The vacuum cryogenic microscopic observation instrument of the present invention is shown in FIG. 1 , and includes an observation chamber 1 , a cold trap 19 , a refrigeration system, a vacuum system, a computer control and a test recording system 33 . The observation room 1 is provided with a special microscope 2, an electronic scale 11, freezing and heating components, a winding lens shielding mechanism 27, and temperature and pressure sensing elements. An electronic scale 11 is arranged on the microscope stage 9, and the electronic scale 11 supports the loading tray 6 through the supports on both sides. The loading tray 6 is located below the microscope objective lens 3, and freezing and heating components are installed above the microscope loading stage 9. A coiled shielding mechanism 27 is arranged in front of the microscope objective lens 3, the cold trap chamber 19 communicates with the observation chamber 1, a vacuum valve 20 is provided between the observation ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com