Welding method and equipment

一种焊接方法、焊接设备的技术,应用在焊接设备、焊接设备、焊接/焊接/切割物品等方向,能够解决不良焊接、结构损伤、热量多等问题,达到提高质量、防止损伤、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

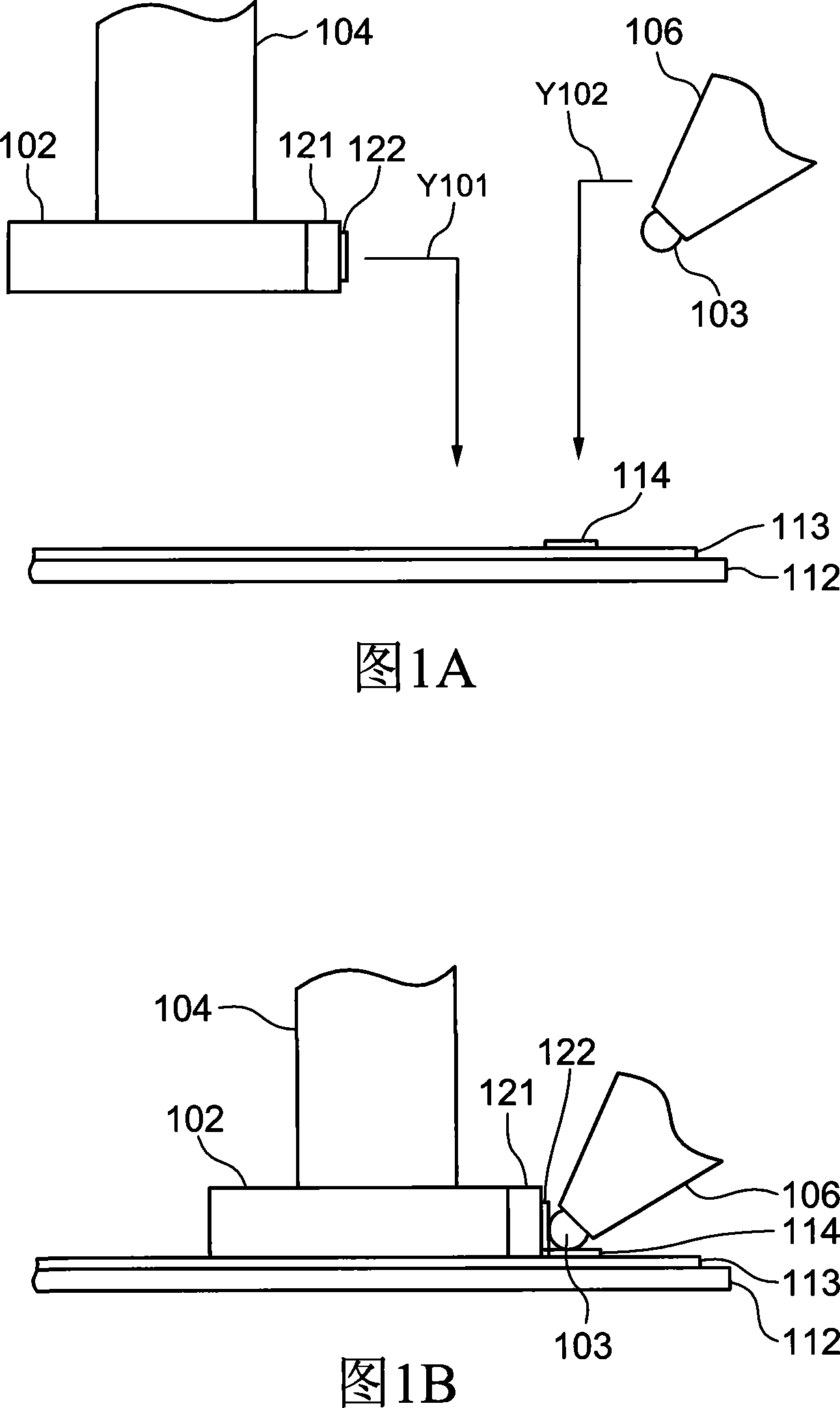

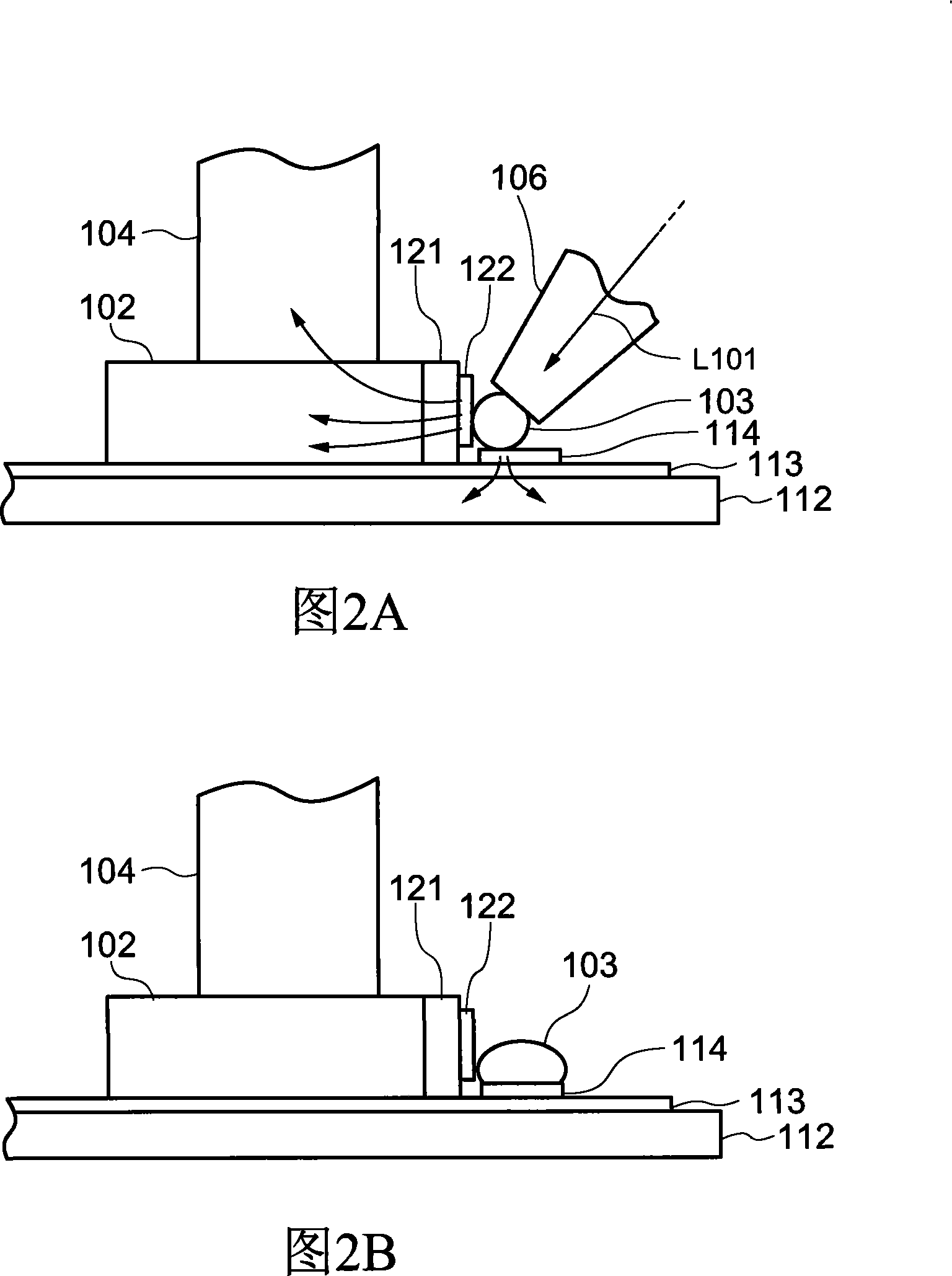

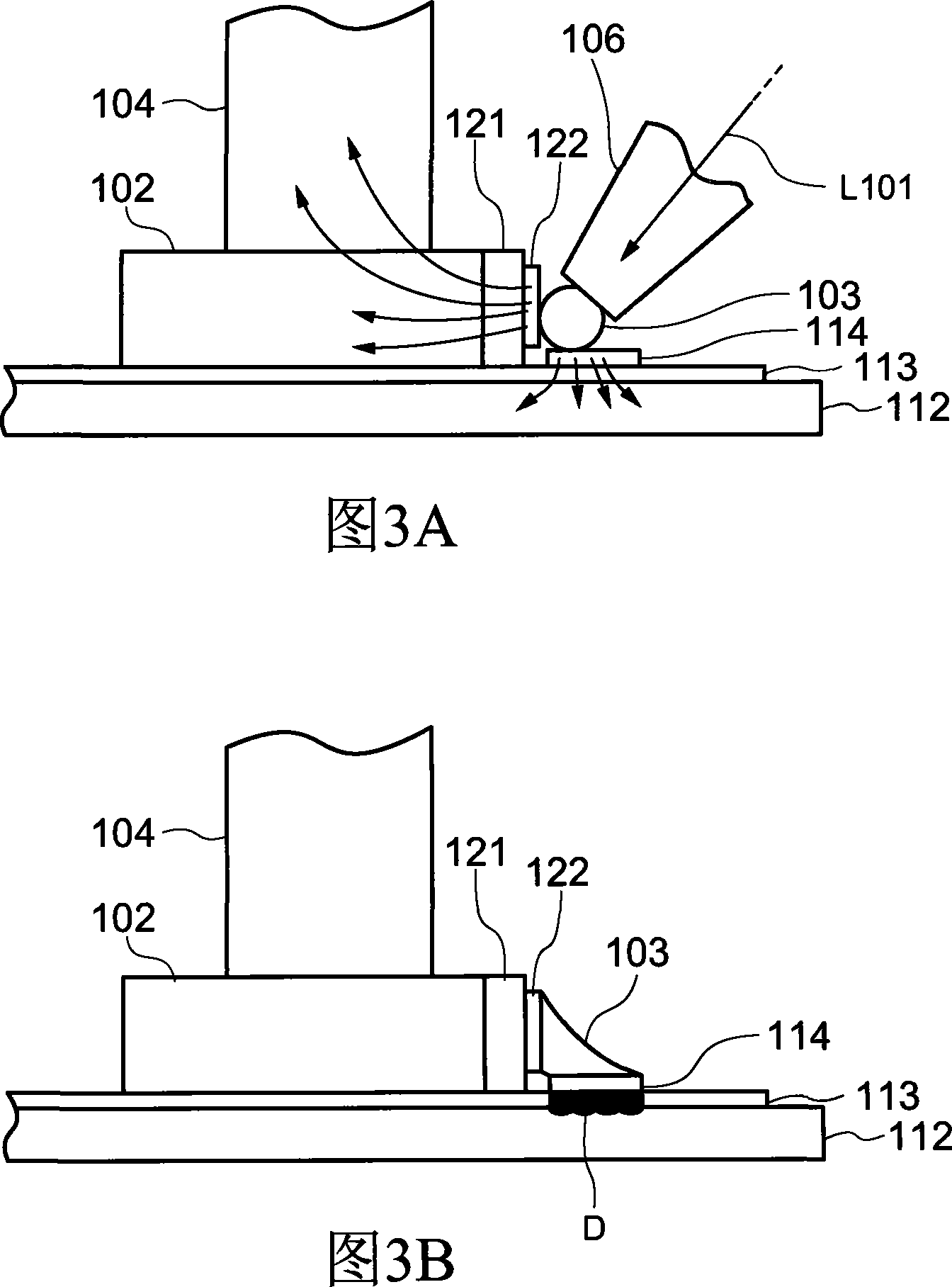

[0057] A first embodiment of the present invention will be described with reference to FIGS. 7 to 16 . FIG. 7 is a schematic structural diagram of a magnetic disk device, and FIG. 8 is a schematic structural diagram of a magnetic head gimbal assembly. 9 to 10 are structural schematic diagrams of the welding equipment, and FIG. 11 is a flow chart illustrating the steps of the welding method. 12 to 16 are explanatory diagrams showing welding states.

[0058] [structure]

[0059] Firstly, the welding equipment involved in this embodiment is used to manufacture the HGA 1 that can be carried on the magnetic disk device 100 as shown in FIG. 7 . Specifically, as shown in FIG. 8 , the soldering equipment can be used when connecting the head slider 2 to the flexible member 12 and the wire 13 that form the suspension member that can constitute the head gimbal assembly 1 . Here, the structure of the HGA 1 will be briefly described with reference to FIG. 8 .

[0060] The HGA 1 is prov...

no. 2 example

[0087] Next, a second embodiment of the present invention will be described with reference to FIGS. 17 to 22 . 17 to 18 are structural schematic diagrams of the welding equipment involved in this embodiment; FIG. 19 is a flowchart showing steps of the welding method; and FIGS. 20 to 22 are explanatory diagrams showing welding states.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com