Oil decanting system for oil-sewage ship oil-sewage tank

A technology for oily sewage and decanting oil, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, separation method, etc., to achieve the effect of low investment, energy saving and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

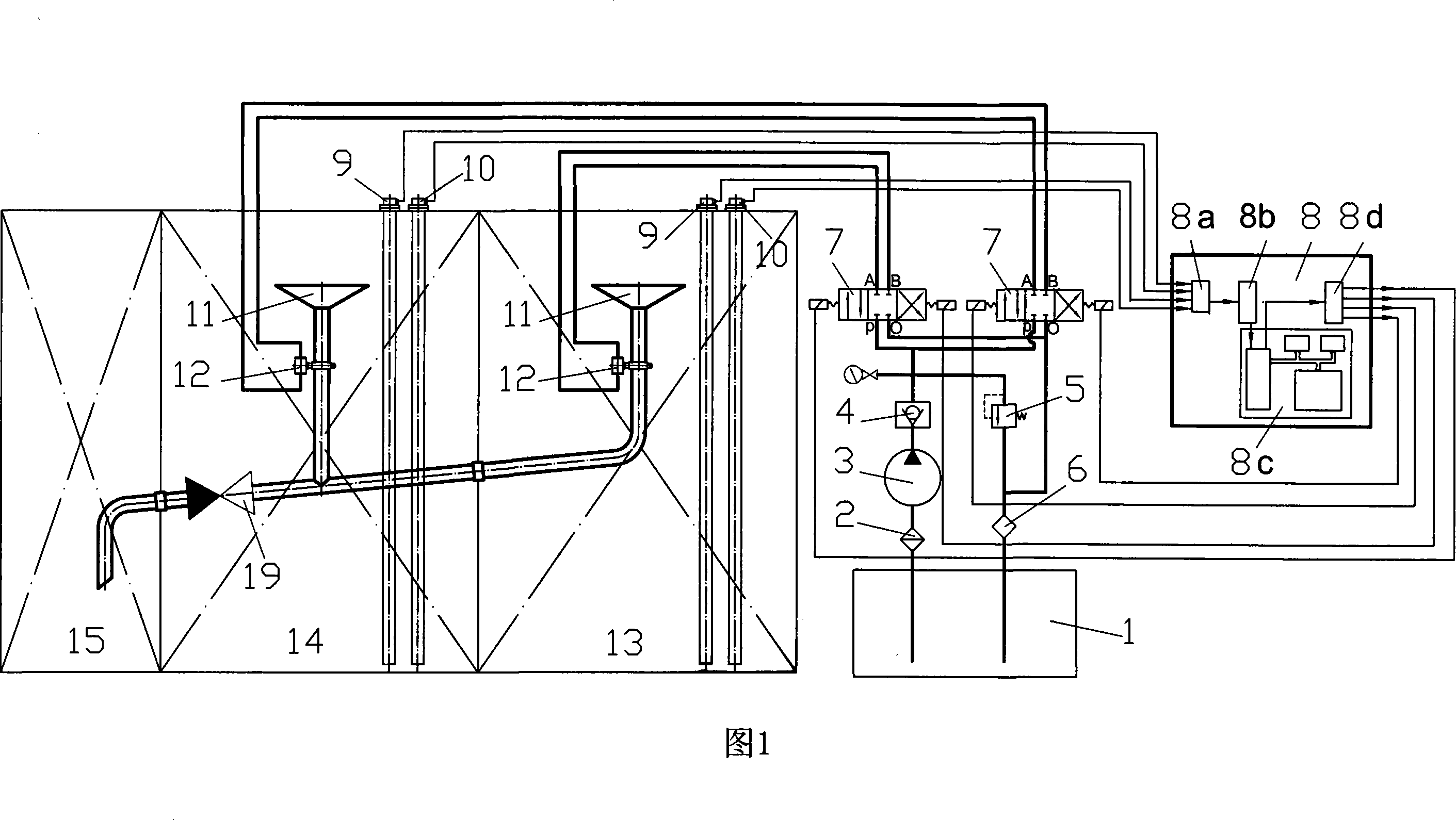

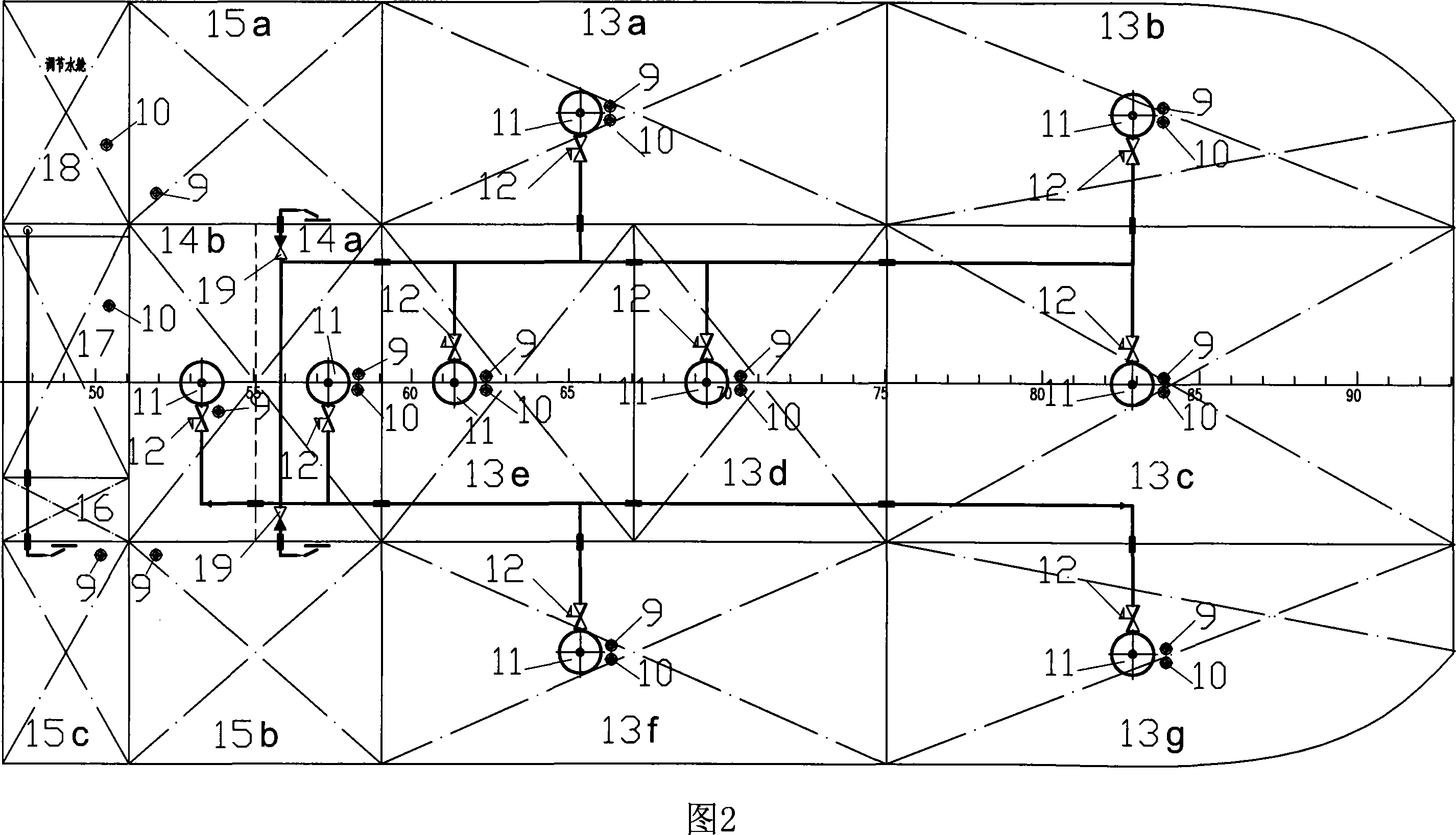

[0013] In order to gain an in-depth understanding of the decanting system of the oily slop tank of the oily slop tank, the description is as follows in conjunction with Figures 1 and 2:

[0014] Figure 1 shows the schematic diagram of the oil decanting system in the oily sewage tank. In the figure, the hydraulic pump 3 absorbs oil from the hydraulic oil tank 1 through the filter 2, supplies the hydraulic oil to the three-position four-way solenoid valve 7 through the check valve 4, and a part of the hydraulic oil returns to the hydraulic oil tank through the overflow valve 5 and the cooler 6 1. Generally, there are two sets of hydraulic pumps 3, one of which is a spare, and the working pressure of the hydraulic oil is 5.3-6 MPa. An oil decanting funnel 11 is set in the middle of the oily sewage tank 13 and the sloping plate oil separation tank 14. The lower part of the oil decanting funnel 11 is connected to a hydraulic remote control valve 12 through a pipeline, and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com