Locomotive wheel hoop fastening ring-binding method

A technology of snap rings and tires, applied in mechanical equipment, furnace types, furnaces, etc., can solve problems such as poor hardenability, unsatisfactory plasticity and toughness, insufficient snap ring elasticity, etc., and achieve the effect of increasing radial elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

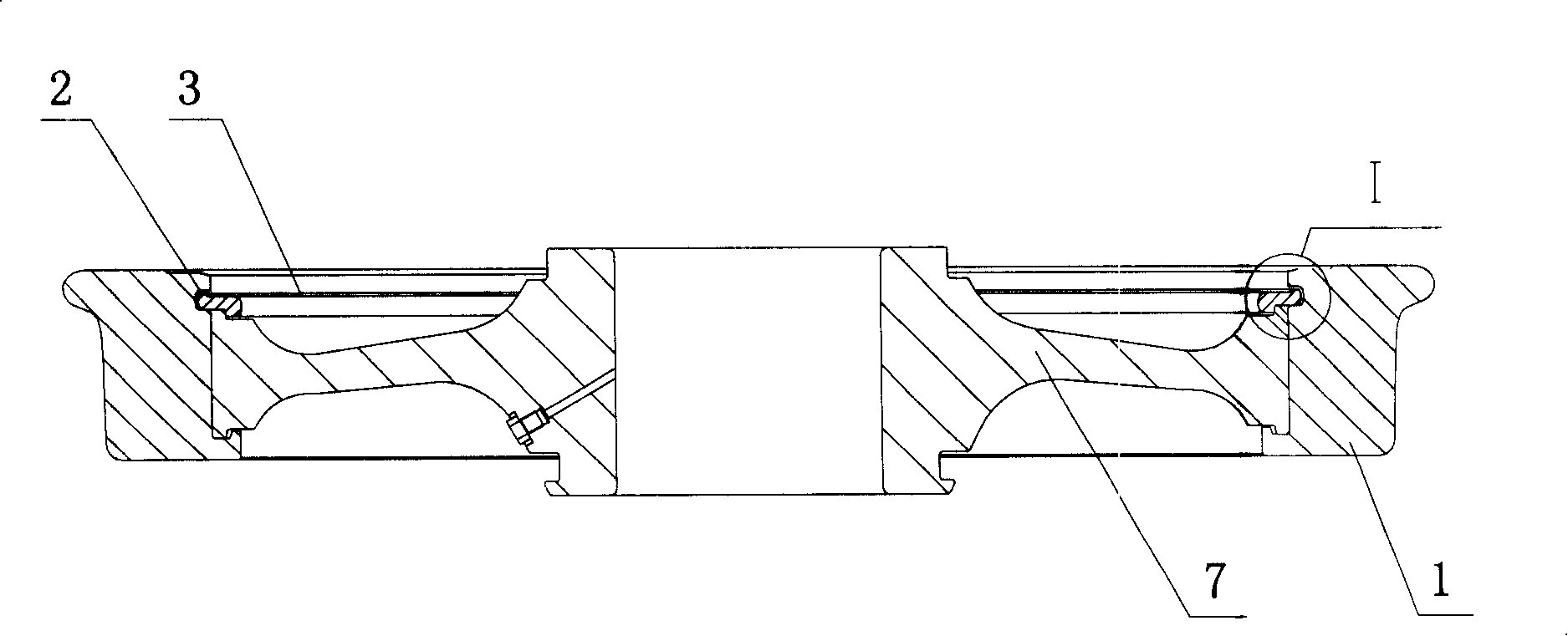

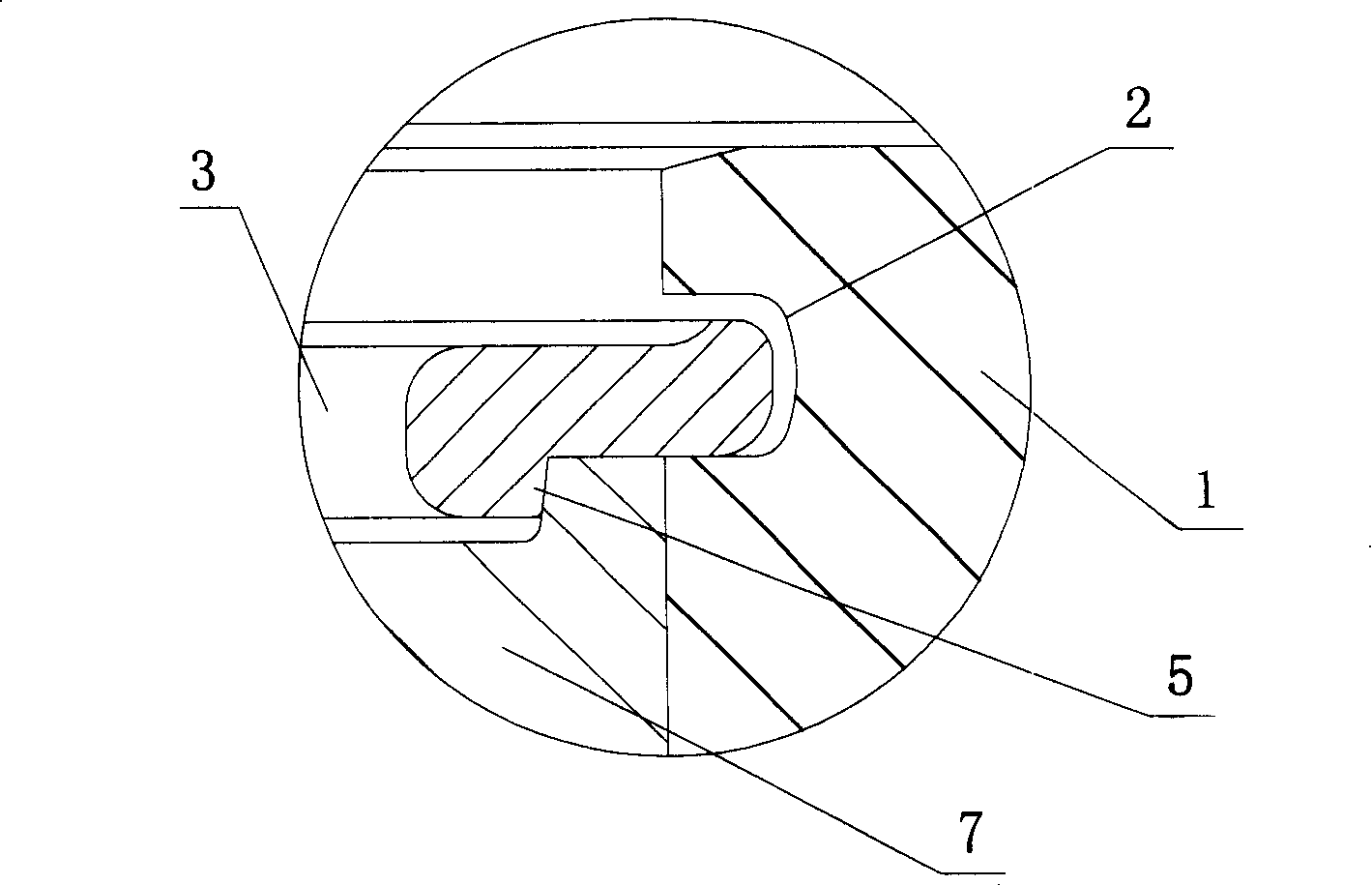

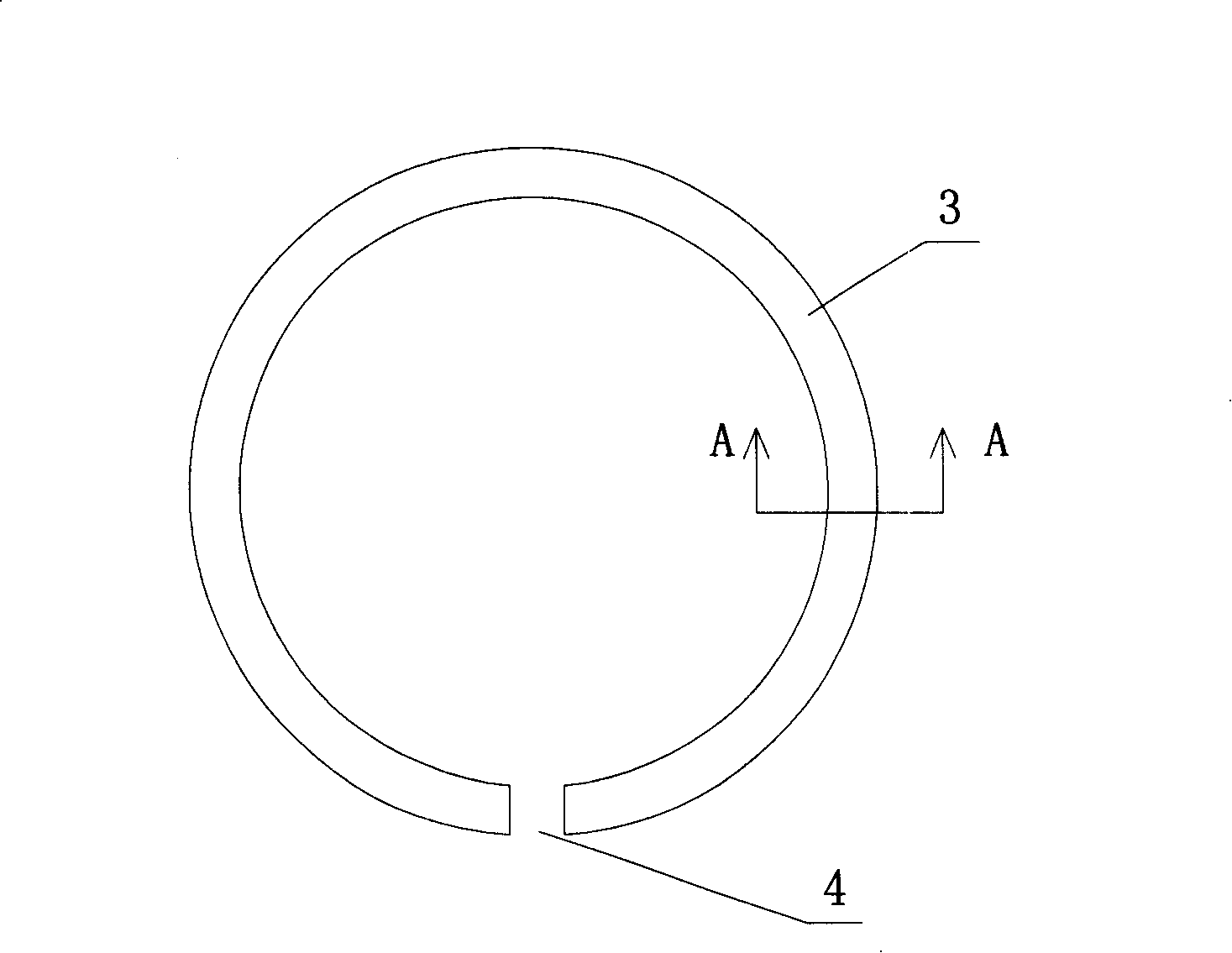

[0035] Example 1, such as Figure 1 to Figure 4 As shown, the snap ring 3 is used for the pre-assembly of the wheel tire 1 of the rail vehicle. After the tire 1 is heat-fitted on the wheel core 7, the snap ring 3 is snapped into the groove 2 of the tire 1, and the snap ring 3 realizes the axial positioning of the wheel core 7 by virtue of its elasticity in the diameter direction.

[0036] In the method for mounting the snap ring on the wheel rim of the motorcycle, before the snap ring 3 is fastened inside the groove 2 of the wheel rim 1, it is processed by a heat-setting process, and the process flow is as follows:

[0037] First, the snap ring 3 is fixedly installed on the heat setting fixture;

[0038] Then, tempering and heating the snap ring 3 with a medium temperature fire within the range of 420-500°C, so that the snap ring 3 can be shaped on the fixture;

[0039] Secondly, the snap ring is continuously tempered and heated within the above temperature range for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com