Engine air admittance regulation system

An air intake adjustment and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of inability to effectively adjust the limit position of the valve piston 14 that can be opened, oil pollution, condensation on the pipe wall, etc., to achieve improvement. The effect of incomplete combustion, reduced emissions, and reduced fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the preferred implementation advantages are specially cited below, together with the accompanying drawings, and are described in detail as follows:

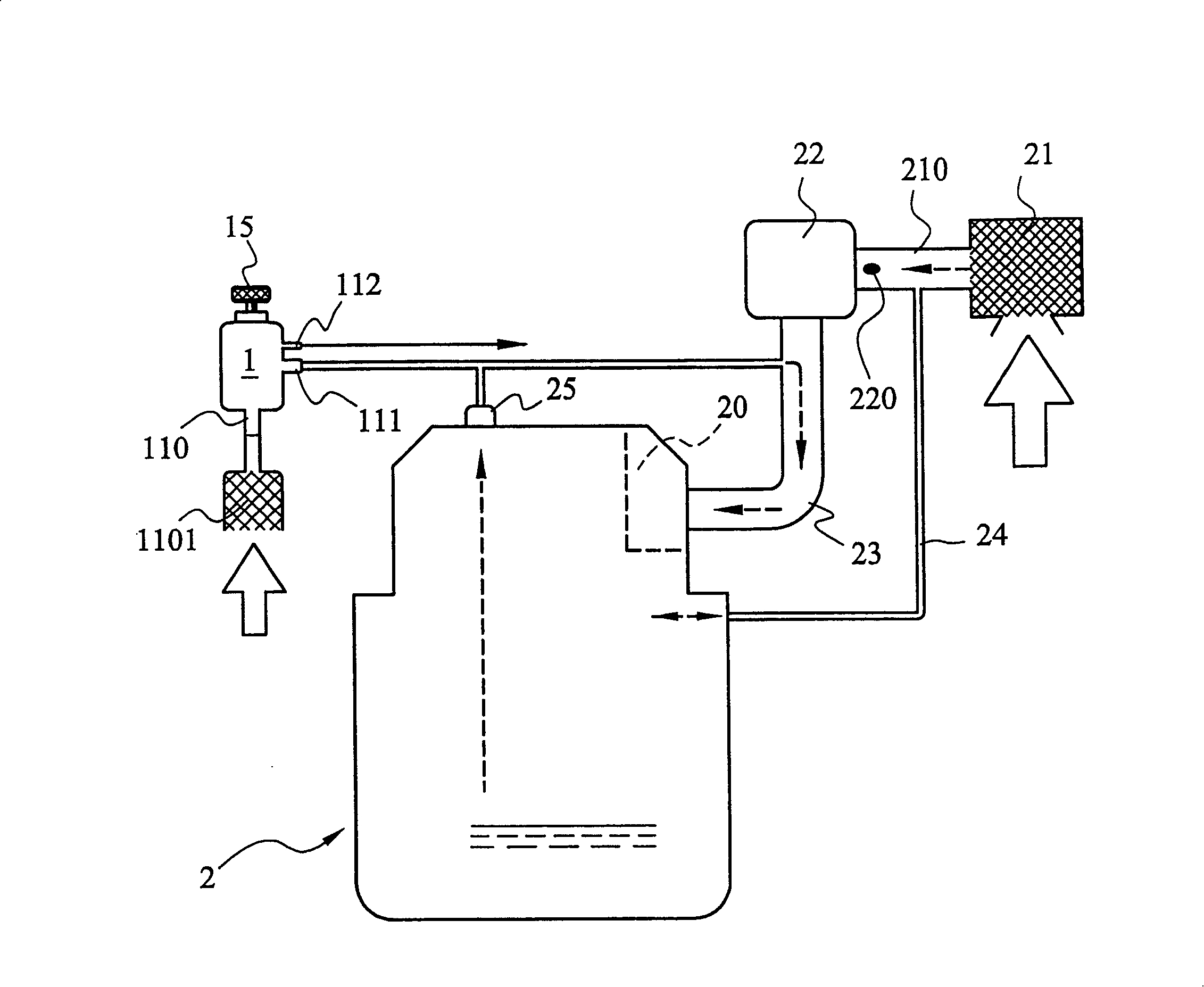

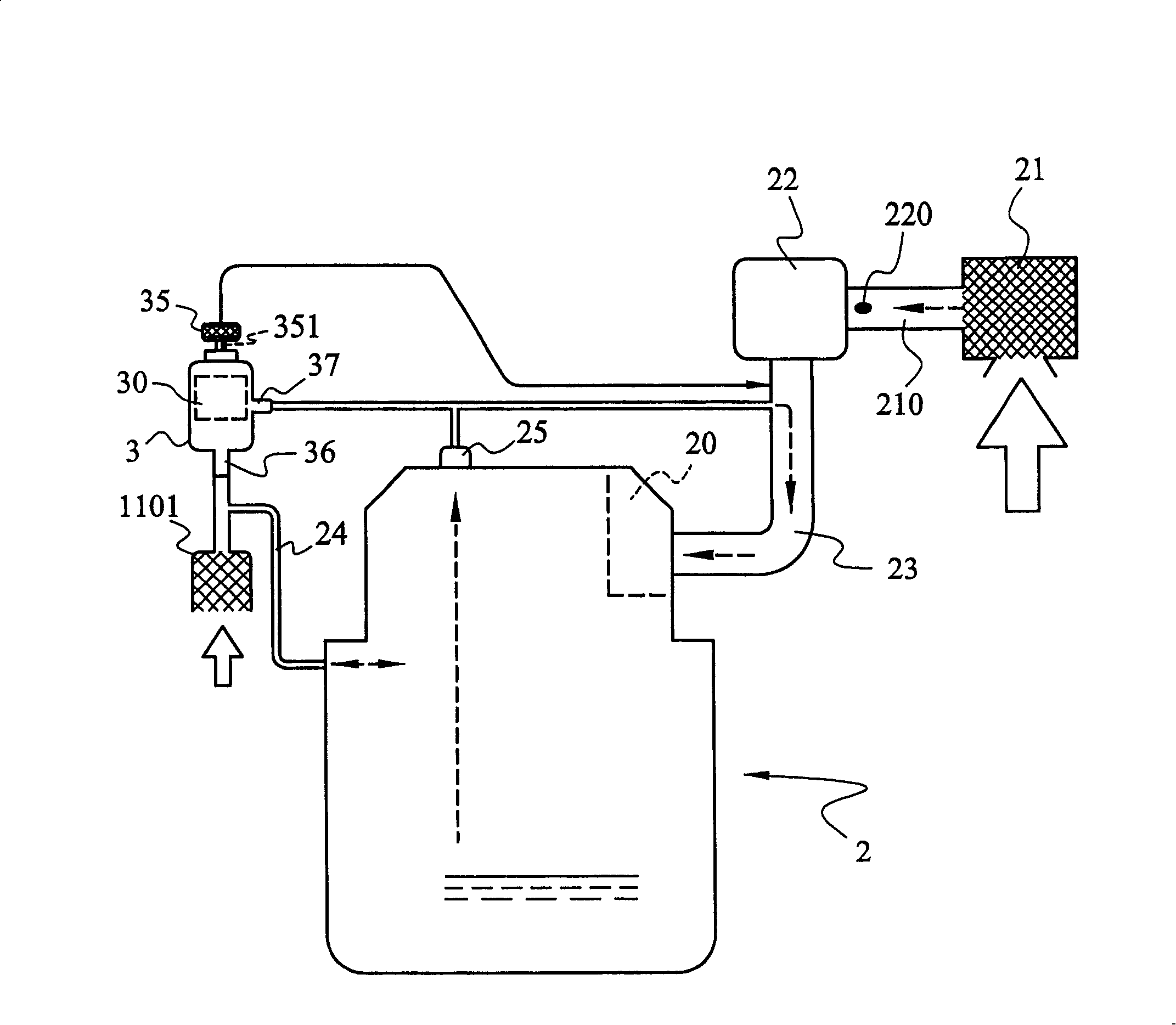

[0060] Please refer to image 3 The shown embodiment of the engine air intake adjustment system includes an air intake adjustment device 3 connected to a breathing hose 24 of an engine 2, used to inhale the blow-by gas in the breathing hose 24 of the engine 2 and blow-by gas from the air filter. 1101 The incoming external air is mixed, and then the mixed gas is sucked into the engine 2 through the intake manifold 23 and the intake port 20 for re-combustion.

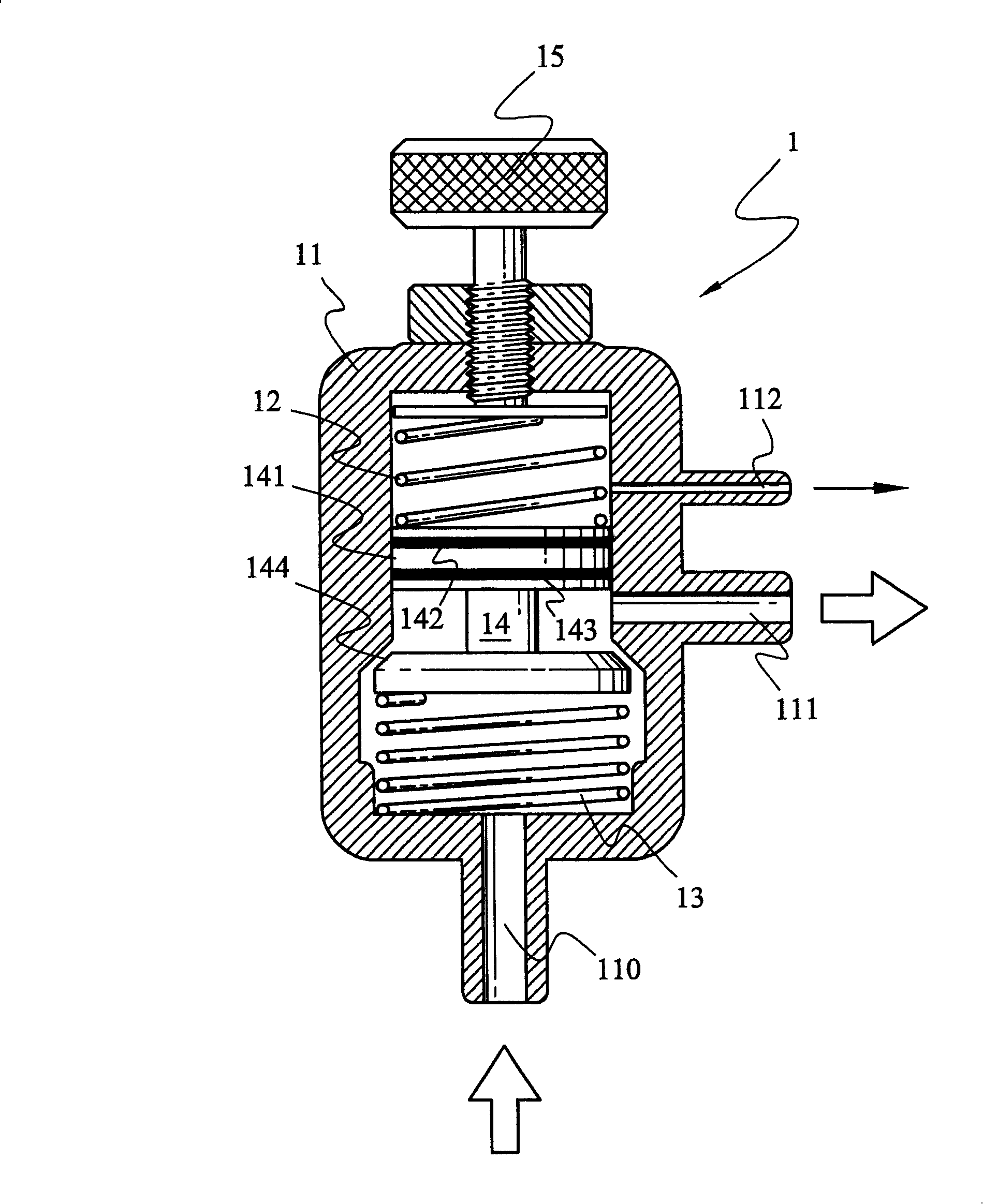

[0061] The air intake regulating device 3 includes a pressure sensing valve 30 and a valve action speed adjusting knob 35 . The pressure sensing valve 30 is provided with a thin hole 351 connected to the negative pressure through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com