Double-drive stirling travelling wave refrigerating device

A refrigerator and dual-drive technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems that are difficult to be used in compact occasions, affect the energy utilization efficiency of the device, and have low thermoacoustic conversion efficiency. , to achieve the effects of suppressing standing wave components, small loss, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

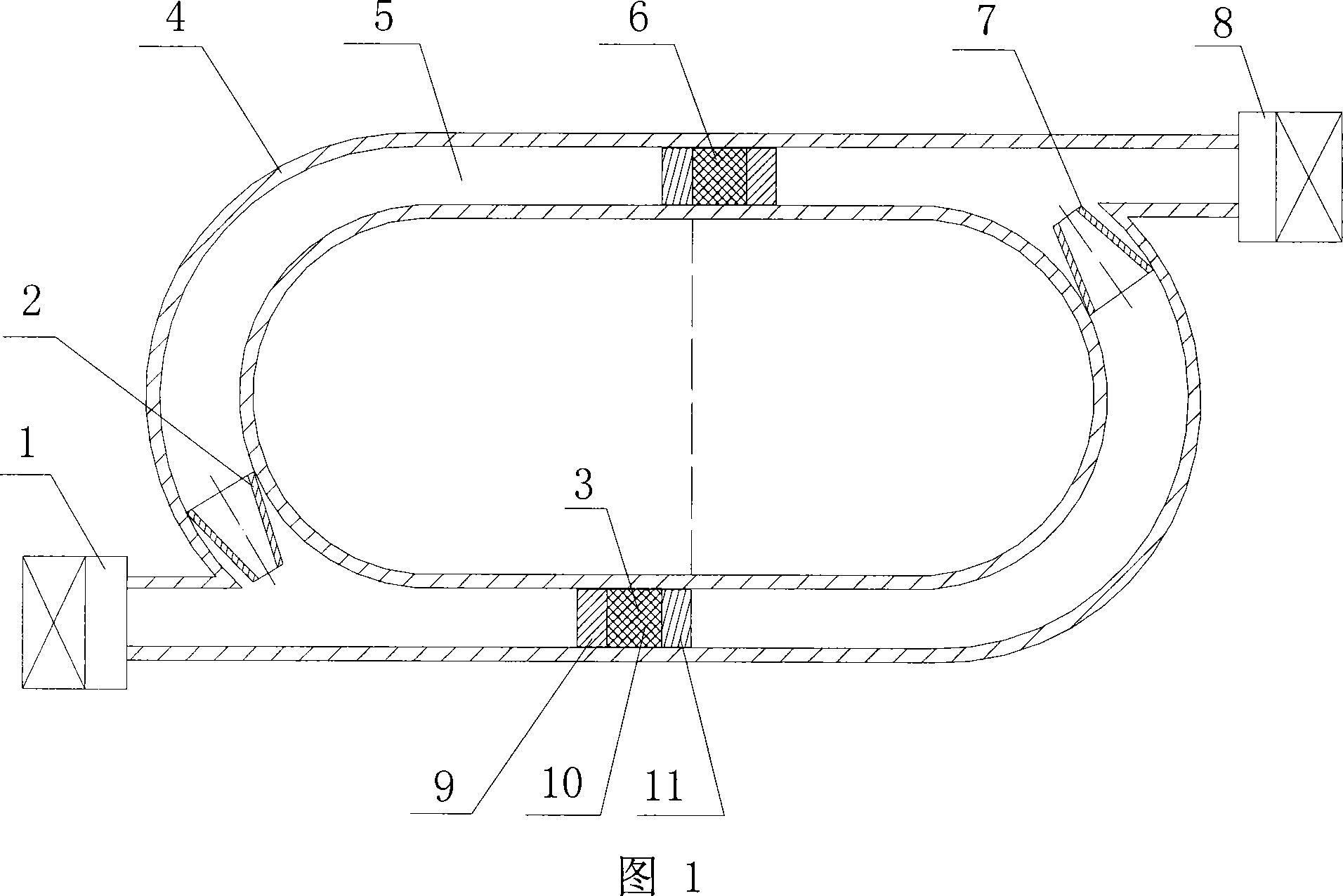

[0016] As shown in Figure 1, the dual-drive Stirling traveling wave refrigerator includes a first vibrator 1, a first anti-traveling wave suppressor 2, a first thermoacoustic cooling element 3, an annular channel housing 4, a second thermoacoustic Refrigeration element 6, the second anti-traveling wave suppressor 7, the second exciter 8; the annular channel housing 4 is an annular traveling wave transmission channel 5, the length of the annular traveling wave transmission channel 5 is one wavelength, and the annular channel housing 4 is symmetrically provided with a first port and a second port, and the first port and the second port communicate with the annular traveling wave transmission channel 5 respectively; At one port (the first vibrator 1 is fixedly connected to the annular passage housing 4), the output end of the first exciter 1 faces the first port, and the second exciter 8 is arranged on the annular passage housing 4 At the second port of the second vibrator (the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com