Integral flux, wind velocity sensor

A wind speed sensor and flow sensor technology, applied in the field of flow sensors, can solve the problems of inability to accurately measure the range of flow changes, large flow and negative pressure fluctuation ranges, and technical implementation angle complexity, etc., to achieve easy popularization and application, and widened measurement range , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

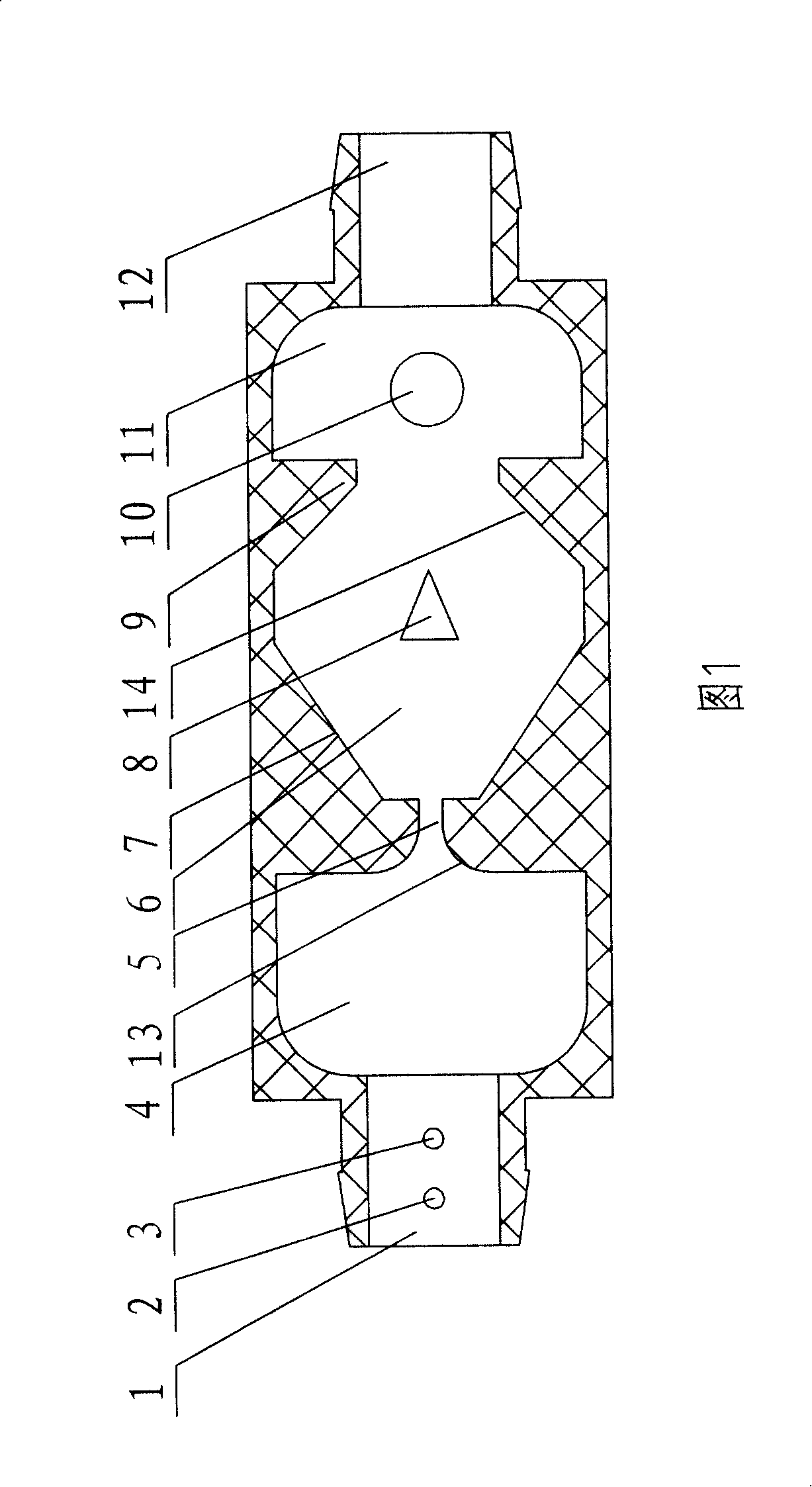

[0016] As shown in Figure 1, the integrated flow sensor and wind speed sensor of the present invention are connected in series by a thermal mass flow sensor and a fluid vibration flow sensor to form a whole, wherein the thermal mass flow sensor is arranged at the front, and the fluid vibration flow sensor The sensor is arranged at the tail, and an air intake stabilizing chamber 4 with airflow buffering effect is arranged in series between the two. The thermal mass flow sensor is composed of the air inlet nozzle channel 1 and the temperature measuring platinum resistance 2 and the speed measuring platinum resistance 3 installed on the side wall. The fluid vibration sensor is composed of the nozzle 5, the fluid vibration generating chamber 6, and the fluid vibration sensor arranged from front to back. The vibration generation chamber exits the barrier wall 9, the outlet steady flow chamber 11 and the air outlet nozzle 12, wherein, in the fluid vibration generation chamber 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com