High-power all solid-state axisymmetric polarization laser for laser machining

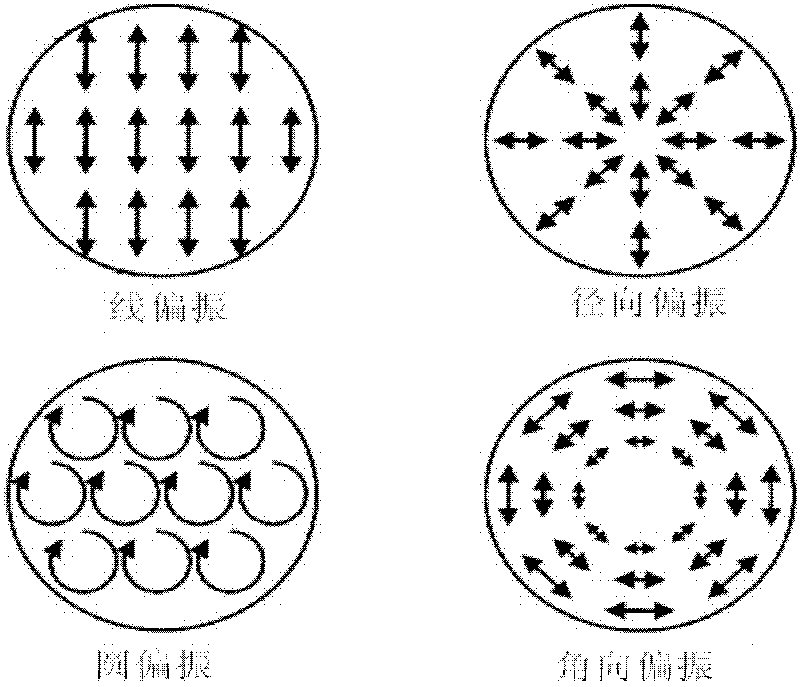

An axisymmetric polarization and laser processing technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problem that the area and absorption efficiency of the material laser beam cannot be effectively controlled, ordinary lasers cannot generate polarization modes, and cannot obtain High-precision processing effects and other issues, to achieve flexible focus field modulation, to achieve symmetry and uniformity, to achieve the effect of beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure of the high-power all-solid-state axisymmetric polarized laser of the present invention will be described in detail below with reference to the drawings and embodiments.

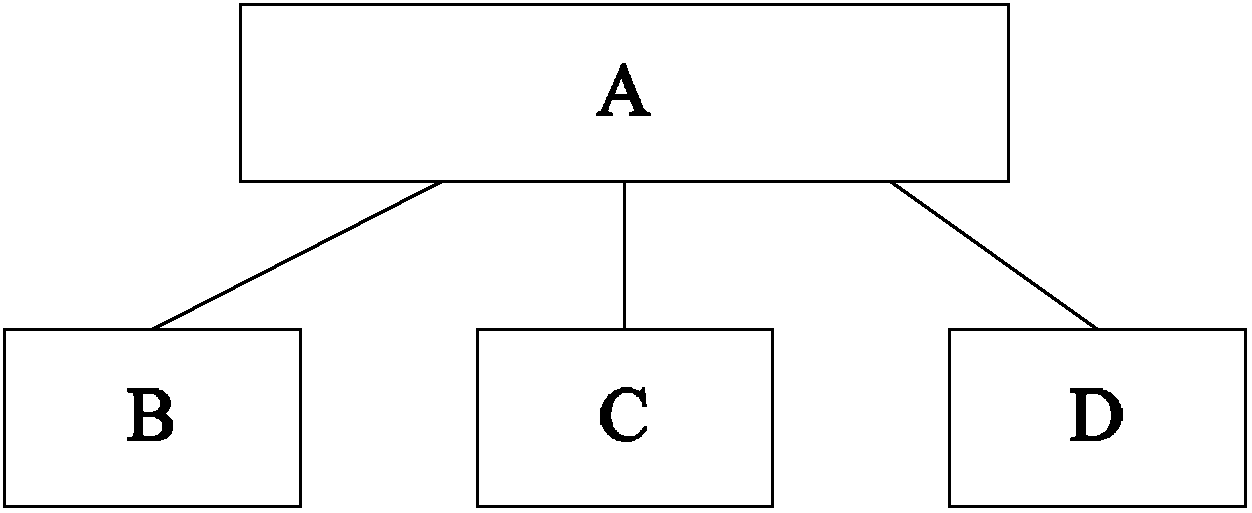

[0030] figure 1 It is a general structural block diagram of a high-power all-solid-state axisymmetric polarized laser for laser processing described in the present invention. Such as figure 1 As shown, the laser includes an all-solid-state laser generating device A, a diode laser DC power supply B, a Q switch driver C and a water cooler D. The all-solid-state laser generating device A uses a laser diode as a light source. Power supply B powers the laser diode. The Q-switch driver C is used to control the output waveform of the all-solid-state laser generating device A. The water cooler D is used to dissipate heat for the all-solid-state laser generating device A.

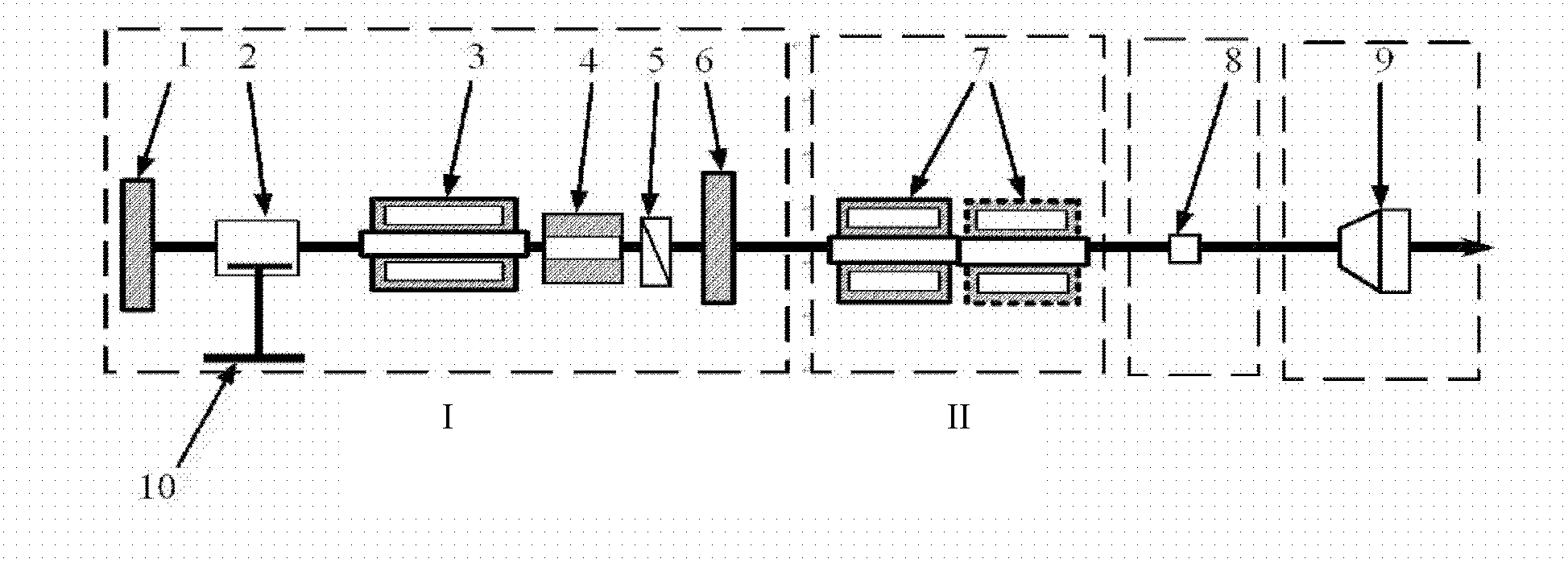

[0031] figure 2 It is a structural schematic diagram of the all-solid-state laser generating device A of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com