Flat-plate type broad frequency sensor for power transmission engineering

A flat-panel sensor technology, applied in the direction of instruments, circuits, measuring electronics, etc., can solve the problems of waveform distortion, large parasitic inductance, no consideration of sensor access sealing reliability and long-term stability, etc., to improve the frequency response range, The effect of reducing parasitic inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

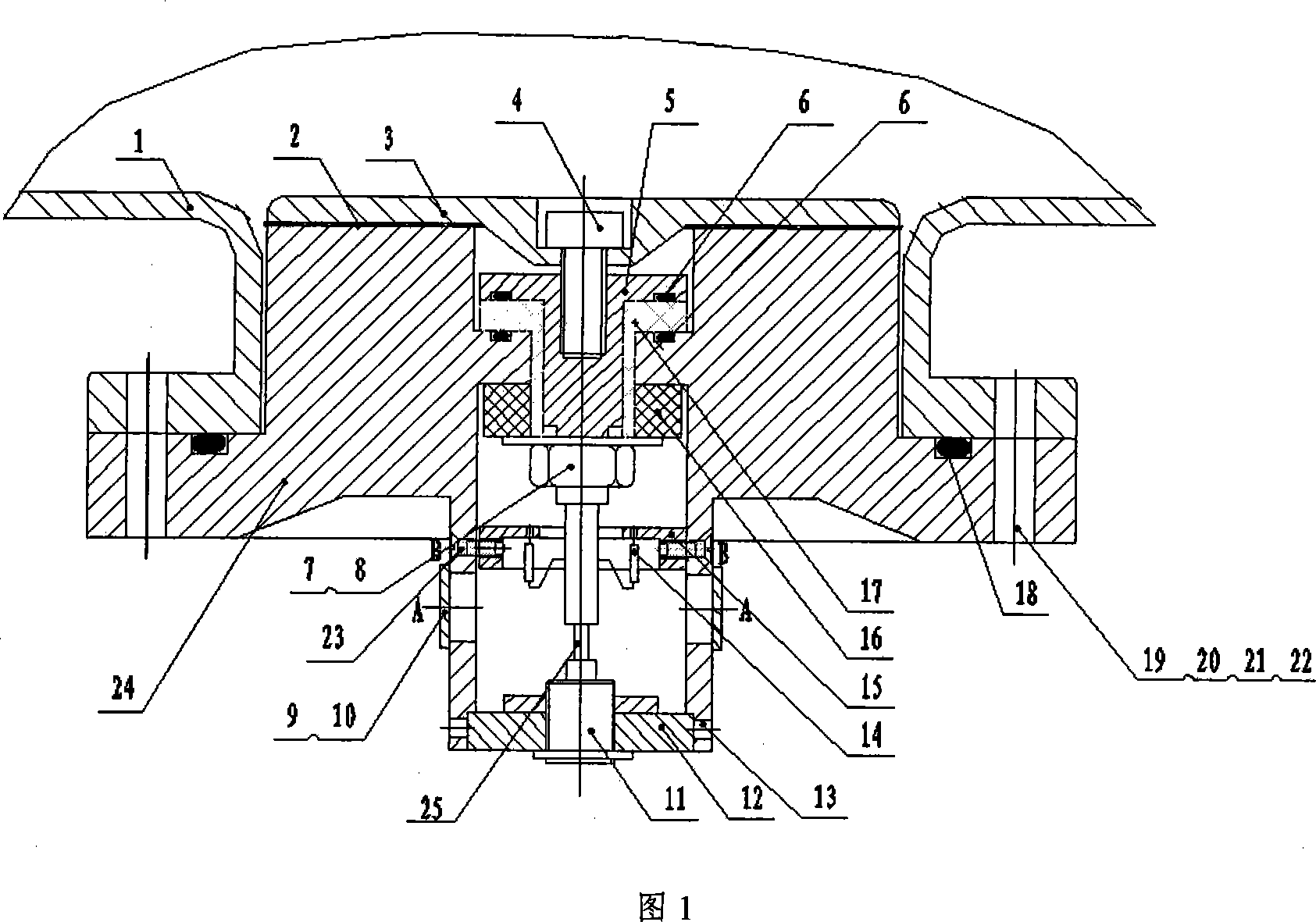

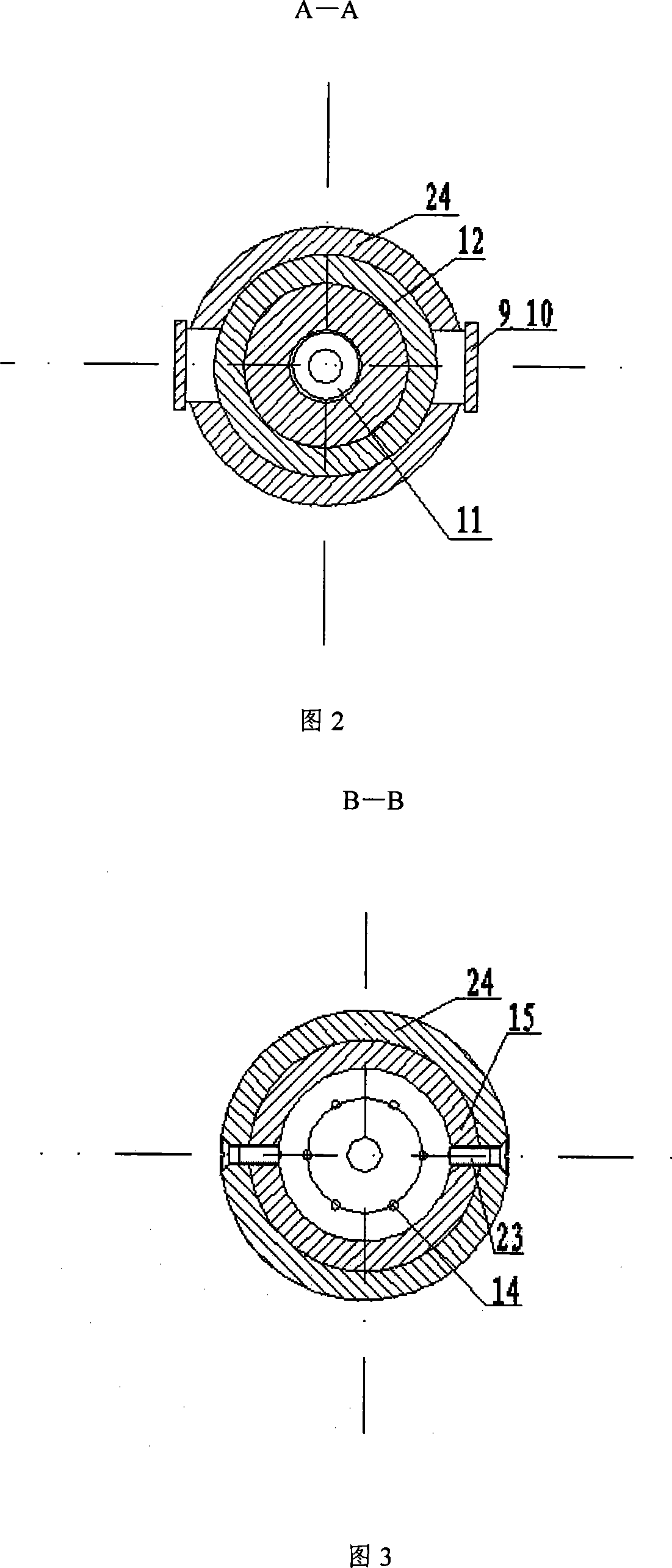

[0021] Instructions marked in Figure 1-3: 1-GIS shell, 2-insulating film, 3-electrode plate, 4-countersunk bolt, 5-connector, 6-sealing ring, 7-nut, 8-washer, 9 -shielding ring, 10-screw, 11-plug, 12-cover, 13-round head bolt, 14-matching resistor, 15-tray, 16-insulating sleeve, 17-insulating sleeve, 18-sealing ring, 19-bolt , 20-nut, 21-flat washer, 22-spring washer, 23-round head bolt, 24-cavity shielding, 25-connecting wire.

[0022] Fig. 1 is a structural diagram of an embodiment of the present invention. The characteristic of the present invention is that the traditional sensor, the matching resistance of the measuring system, the signal shielding protection function and the connector connecting the measuring cable are integrated into one by using the capacitive voltage divider composed of the capacitive sensor.

[0023] The stray capacitance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com