Piston for an internal combustion engine and covering ring for the cooling duct of a piston of said type

一种冷却通道、内燃机的技术,应用在活塞环、活塞、机械设备等方向,能够解决昂贵、装配困难、不受欢迎等问题,达到冷却简单、装配简单、结构简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

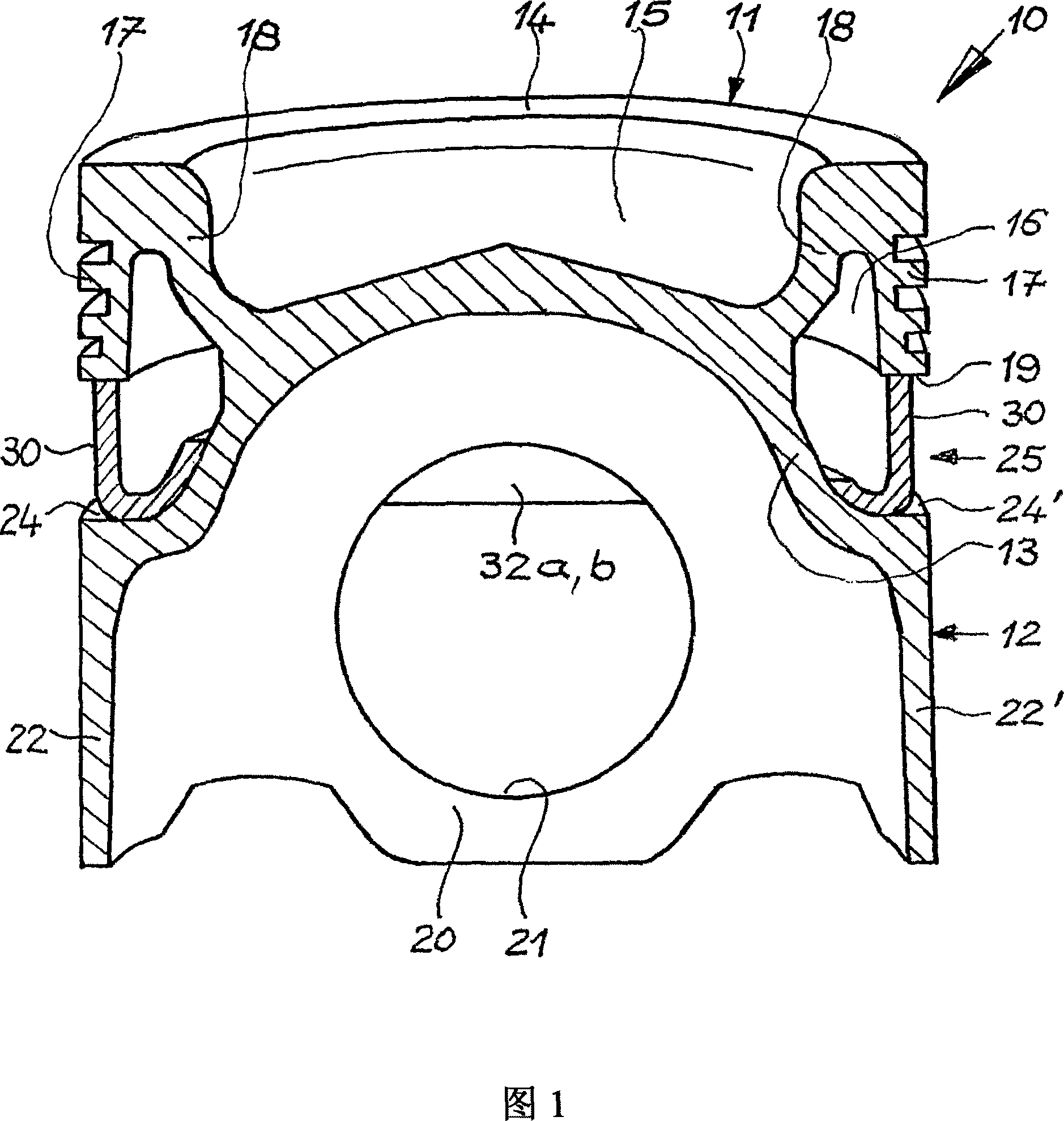

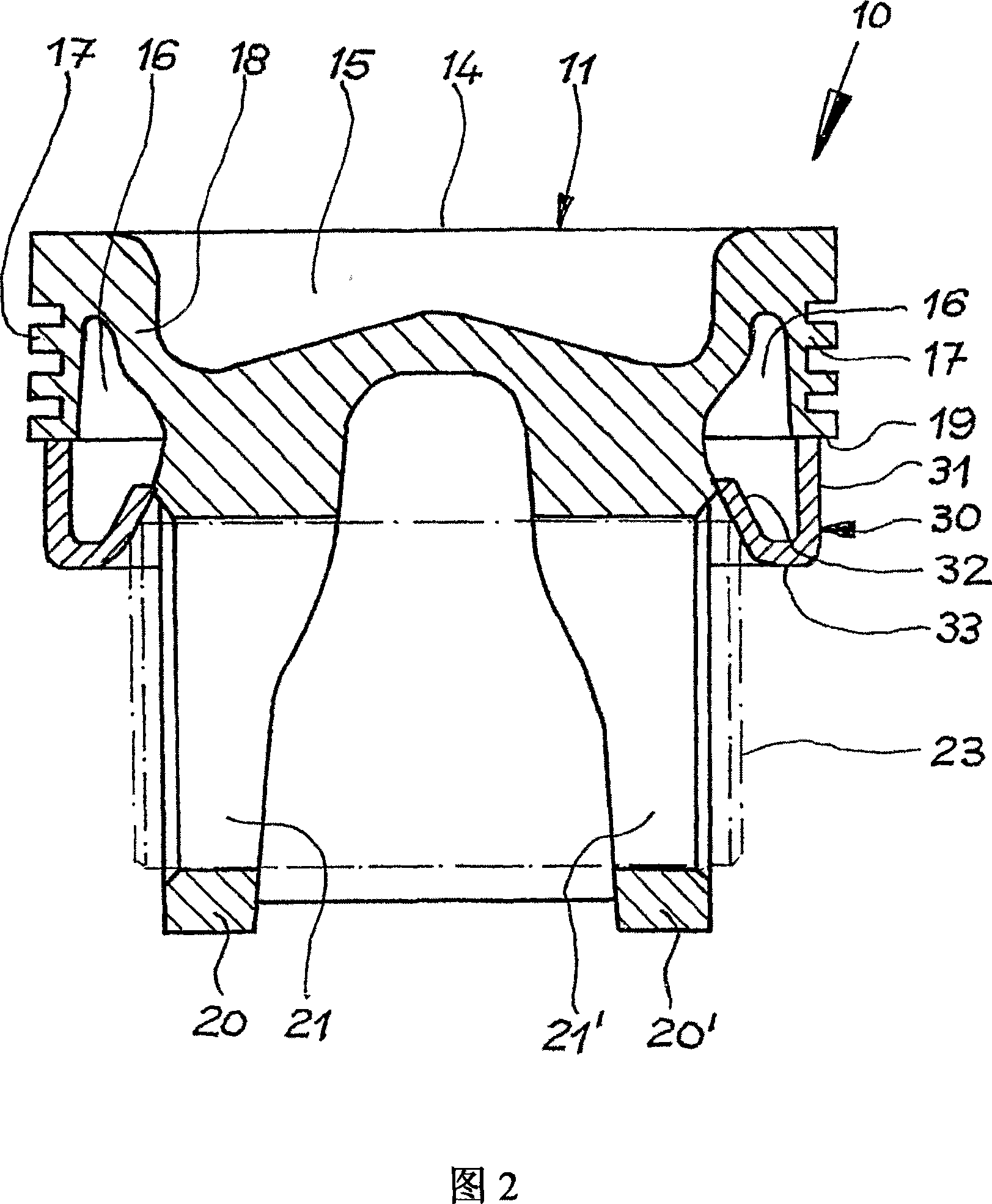

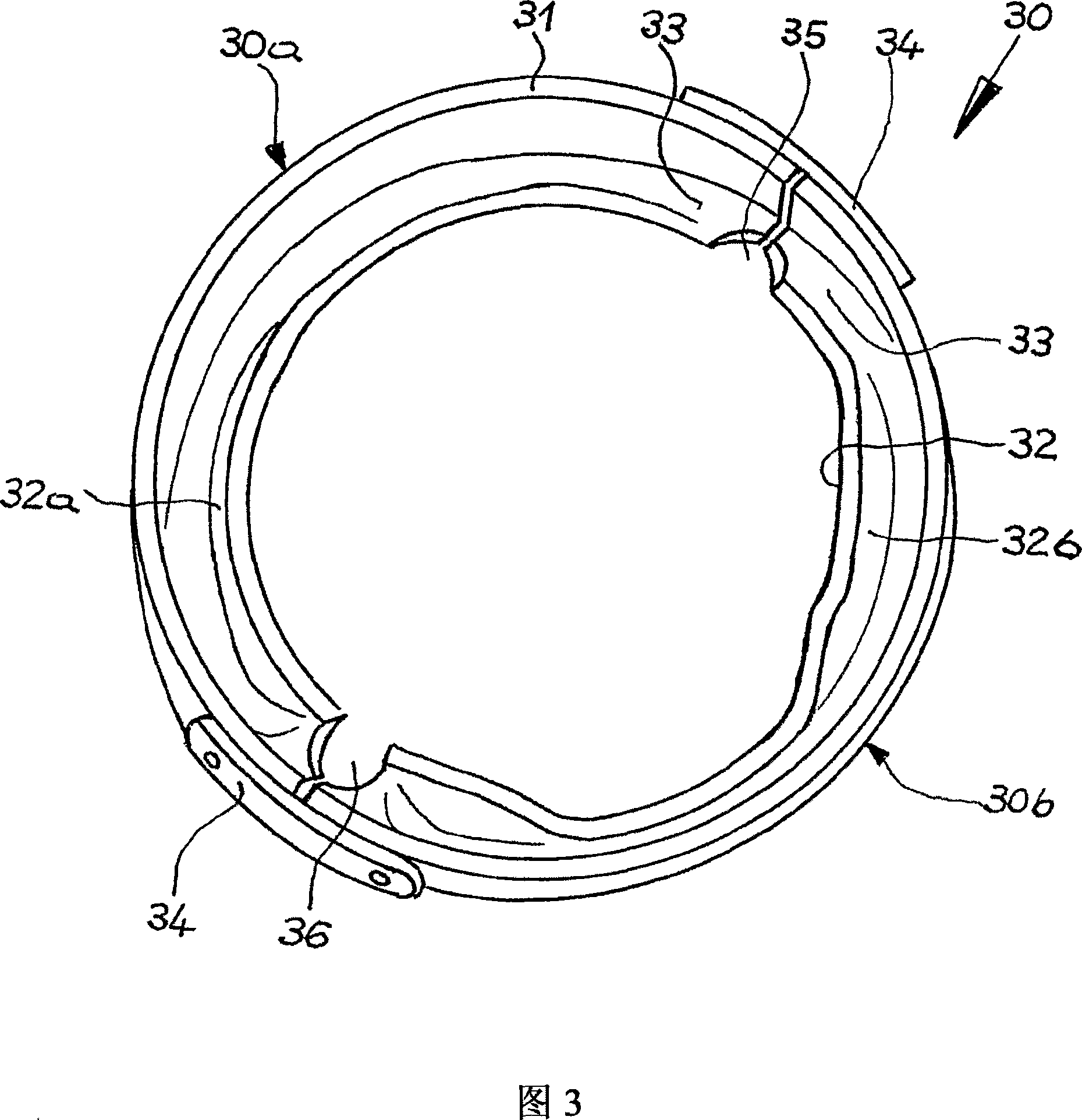

[0019] 1, 2 and 4 show a single-piece internal combustion engine piston 10 . The piston 10 is made of steel

[0020] It is formed and has a piston head 11 and a piston skirt 12, which are integrally connected to each other by means of a piston skirt connection 13. The piston head 11 has a piston crown 14 and a combustion chamber 15 . In the radially outer region of the piston head 11 there is an annular surrounding cooling channel 16 whose radially outer boundary is formed by a ring wall 17 formed on the piston crown 14 and whose radially inner boundary It is composed of ring ribs 18 . In this case, the ring wall 17 serves as a piston ring carrier and terminates in a horizontal end face 19 facing the piston skirt 12 .

[0021] Formed on the piston head 11 are two pin seats 20, 20', which comprise two aligned pin seat holes 21, 21'. The end faces of the piston pin seats 20, 20' are set back relative to the ring wall 17 in the direction of the longitudinal axis of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com