Method for processing valve mechanism constituting member

A processing method and valve mechanism technology, which are applied in the direction of variable displacement pump components, pump components, mechanical equipment, etc., can solve the problems of weakened pulsation reduction effect, inability to form fine shapes, rough surface wear, etc., and achieve long-term maintenance of pulsation reduction effect. Stable, stable pulsation reduction effect, effect of reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings.

[0048] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

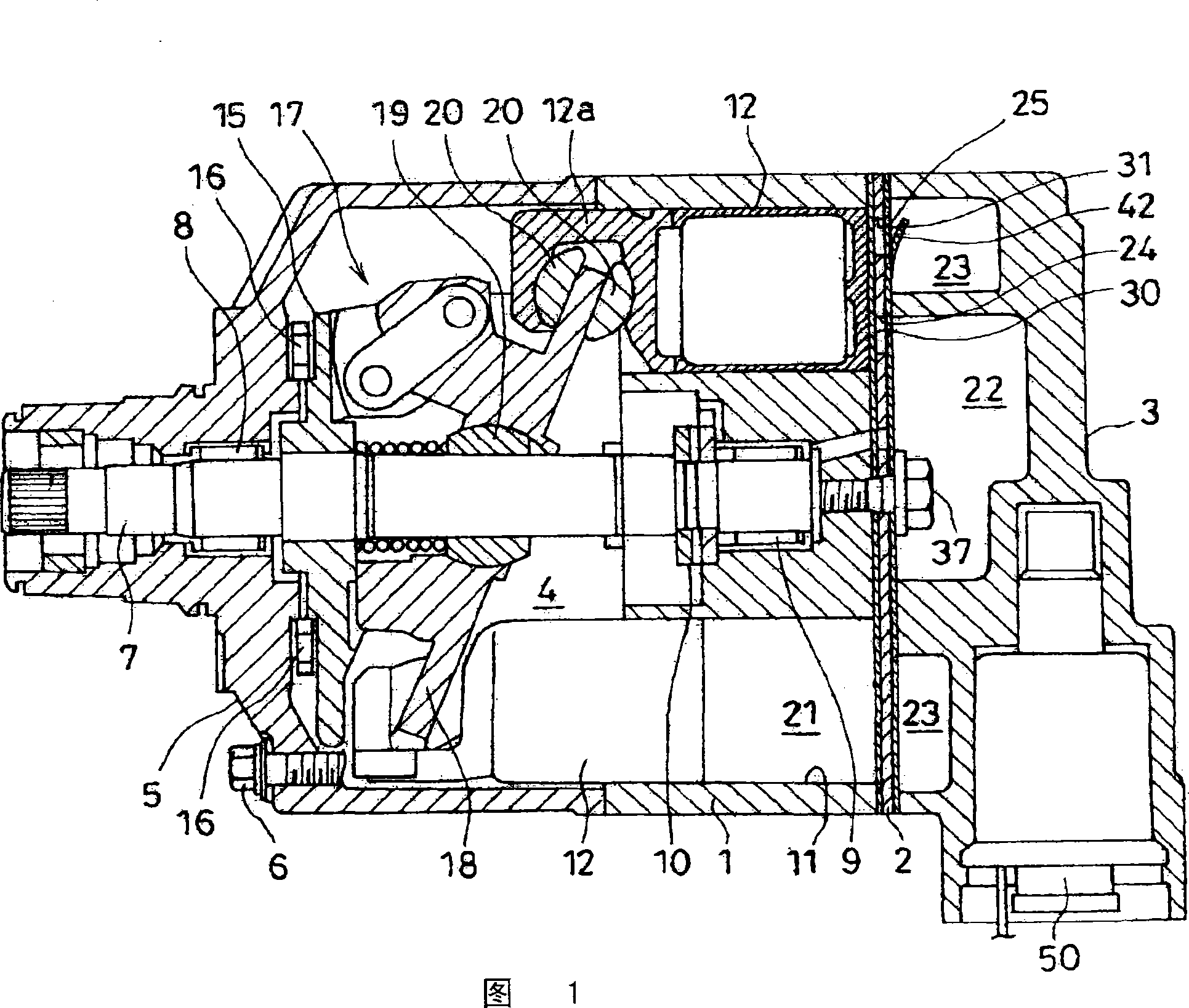

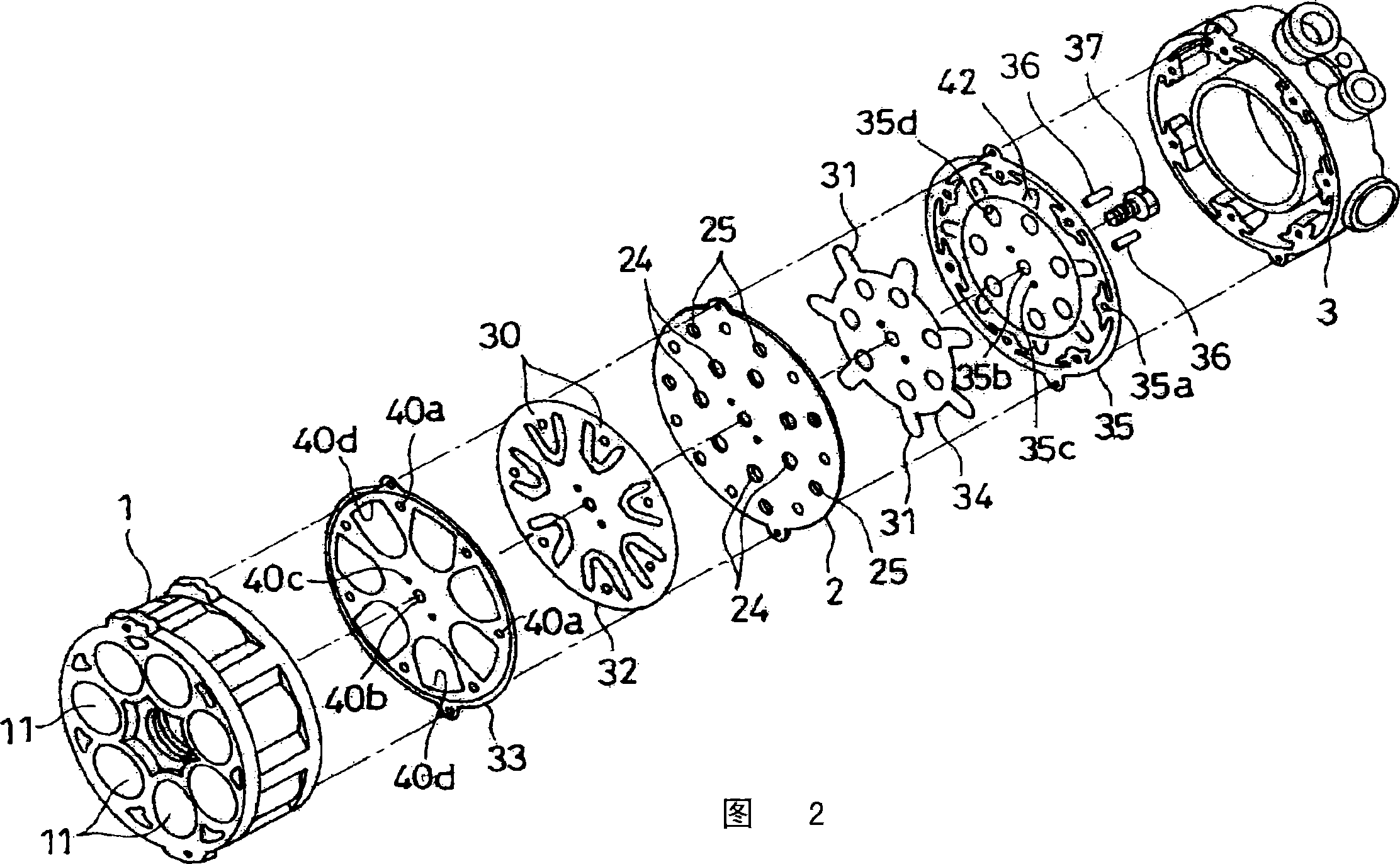

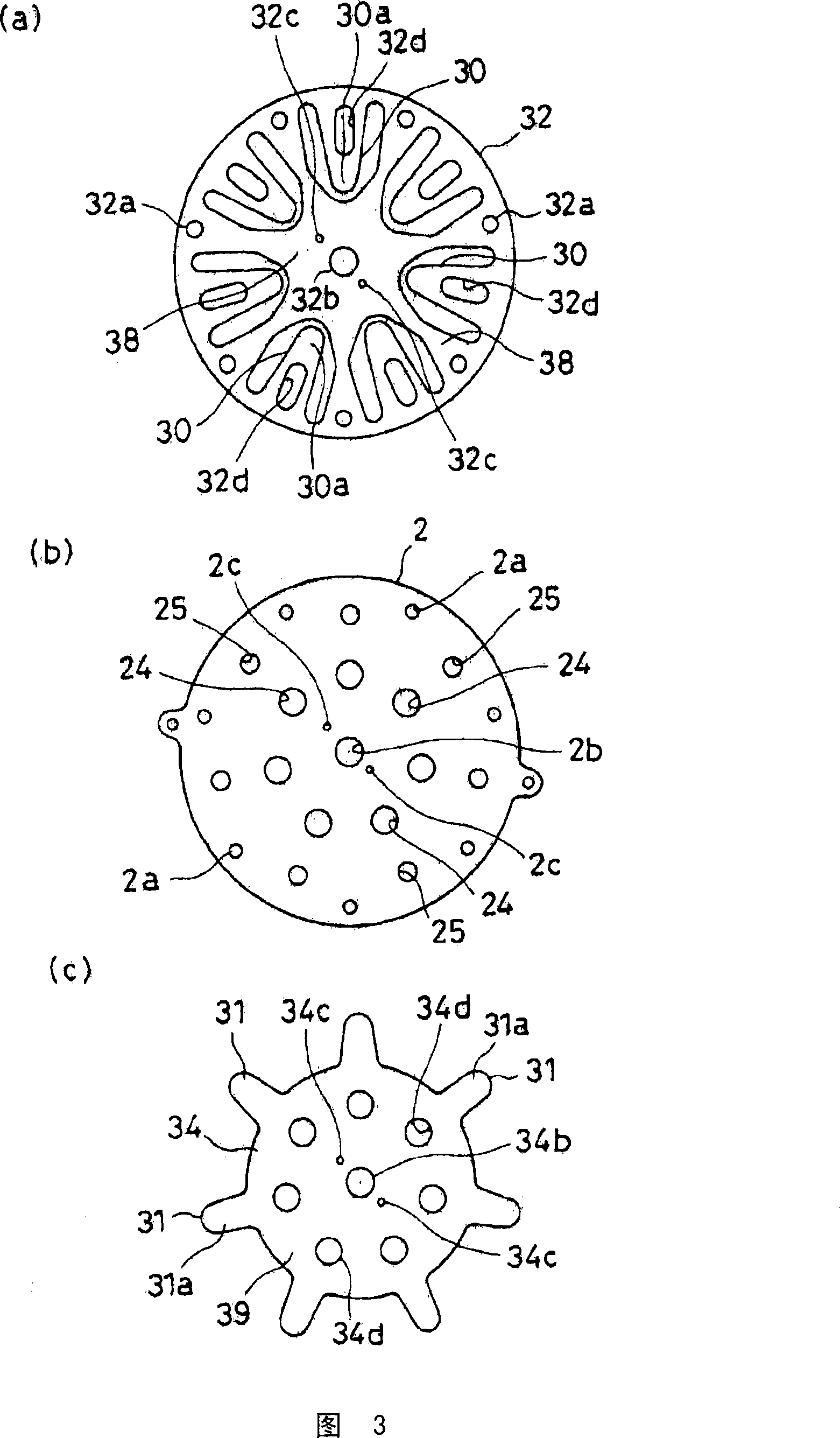

[0049]FIG. 1 shows a reciprocating compressor using a valve mechanism according to the present invention. This reciprocating compressor is constituted by having the following parts: a cylinder block 1; a rear cylinder head 3 assembled on the rear side of the cylinder block 1 through a valve plate 2; The front side of the cylinder block 1 defines a front cylinder head 5 of a crank chamber 4 . The above-mentioned front cylinder head 5 , cylinder body 1 , valve plate 2 and rear cylinder head 3 are fastened together by fastening bolts 6 in the axial direction.

[0050] In the crank chamber 4 defined by the front cylinder head 5 and the cylinder block 1 , a drive shaft 7 with one end protruding from the front cylinder head 5 is acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com