High-frequency vibrating multi-channel integration sloping plate grading thickening equipment

A high-frequency vibration, multi-channel technology, applied in the direction of solid separation, wet separation, settling tanks, etc., can solve the problems of effective adjustment of section size of ungradable units, change of return water properties, low density efficiency, etc., to solve fine Particle short circuit and circulation problems, shortened overflow discharge path, and high fractional concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

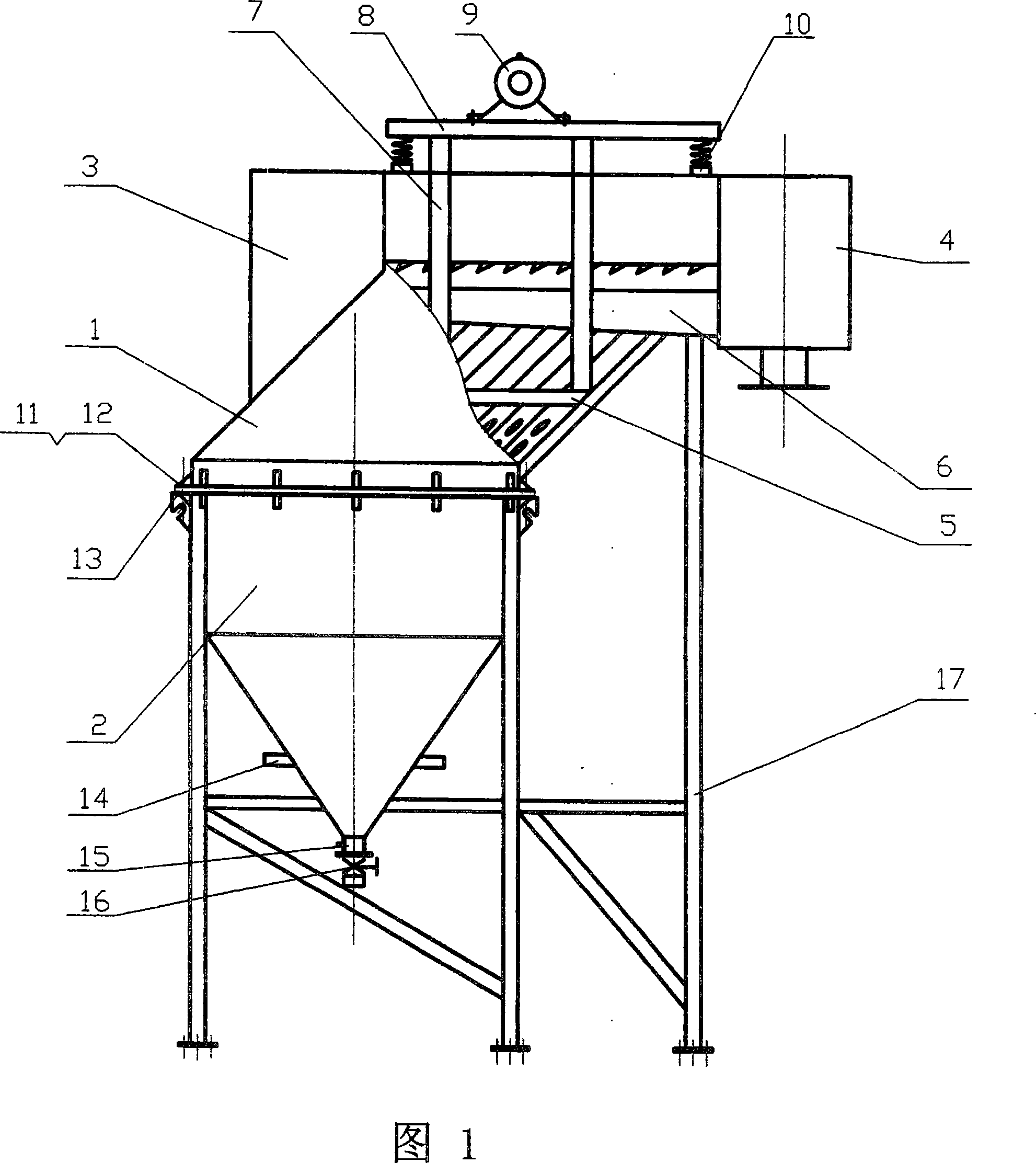

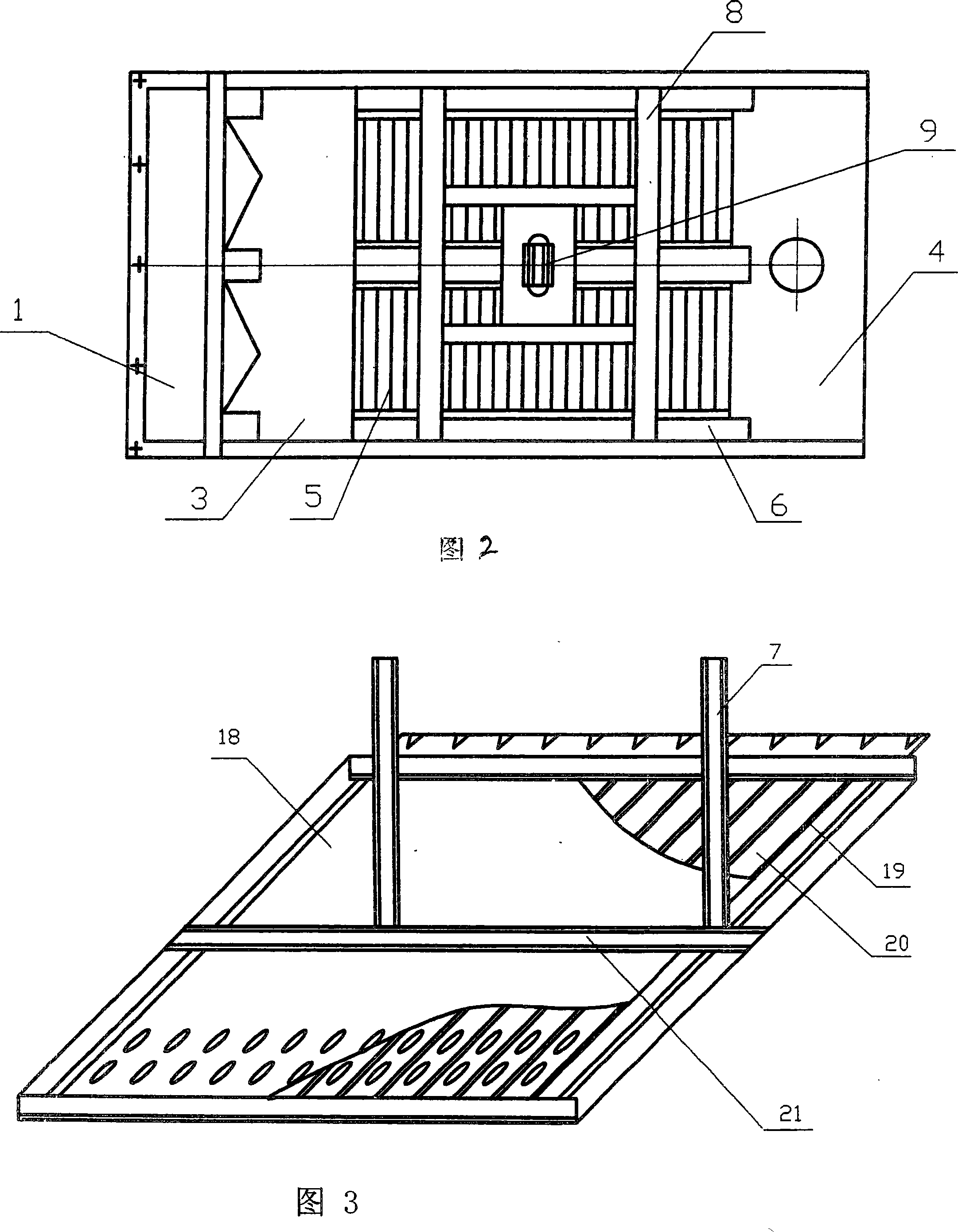

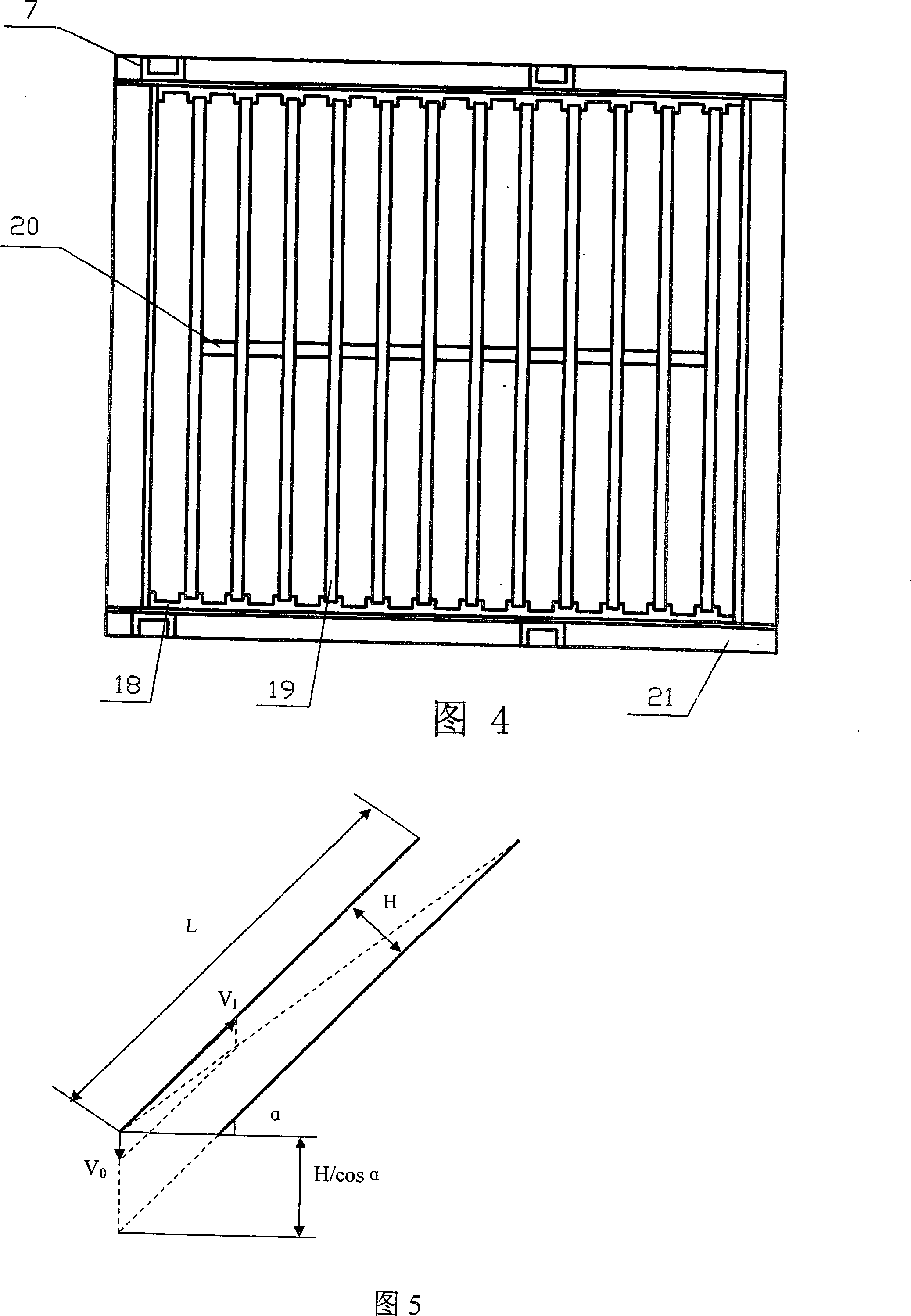

[0010] Example 1: In a certain ilmenite beneficiation plant, before flotation, the pulp needs to be concentrated and the 19 μm slime should be removed at the same time, the feeding pulp concentration is 10%, and the flow rate is 450m 3 / h, it is required that the efficiency of desliming according to 19μm classification should reach more than 50%, and the concentration of underflow sand settling should be greater than 30%. According to the provided graded concentration pulp parameters, the theoretical calculation requires a graded concentration equipment area of 150m 2 , design a settlement area according to the content of the present invention to be 150m 2 The high-frequency vibration multi-channel integrated inclined plate thickening and classifying equipment is used for the thickening and classifying desliming of the pulp. The graded enrichment area of the equipment is composed of three inclined plate group modules, and the settlement area of each inclined plate group...

Embodiment 2

[0011] Example 2: A pyrite ore dressing plant needs to concentrate the flotation concentrate and return water, and the set flow rate of the ore feeding slurry is 110m 3 / h, the pulp concentration is 15%, and the sedimentation velocity of the material is 1.2m / h. It is required that the concentrated underflow concentration of the concentrate should reach more than 45%, the overflow is clear water, and the return water rate is greater than 70%. According to the given pulp properties and concentrated return water requirements, the settlement area of the thickening equipment needed for theoretical calculation is 92m 2 , it is 100m to design and manufacture a settling area according to the content of the present invention 2 The high-frequency vibration multi-channel integrated inclined plate thickening equipment is used for the concentration and return of given materials. The enrichment part of the equipment is composed of three inclined plate group modules with the same structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com