Gas shielded arc welding method for improving electrical arc self-regulation performance and preventing welding stick from burning back

A gas shielding and welding wire technology, used in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of weak arc self-adjustment performance, welding wire burnback, unstable arc length, etc., to eliminate the phenomenon of welding wire burnback, Small change in arc length and improved self-tuning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

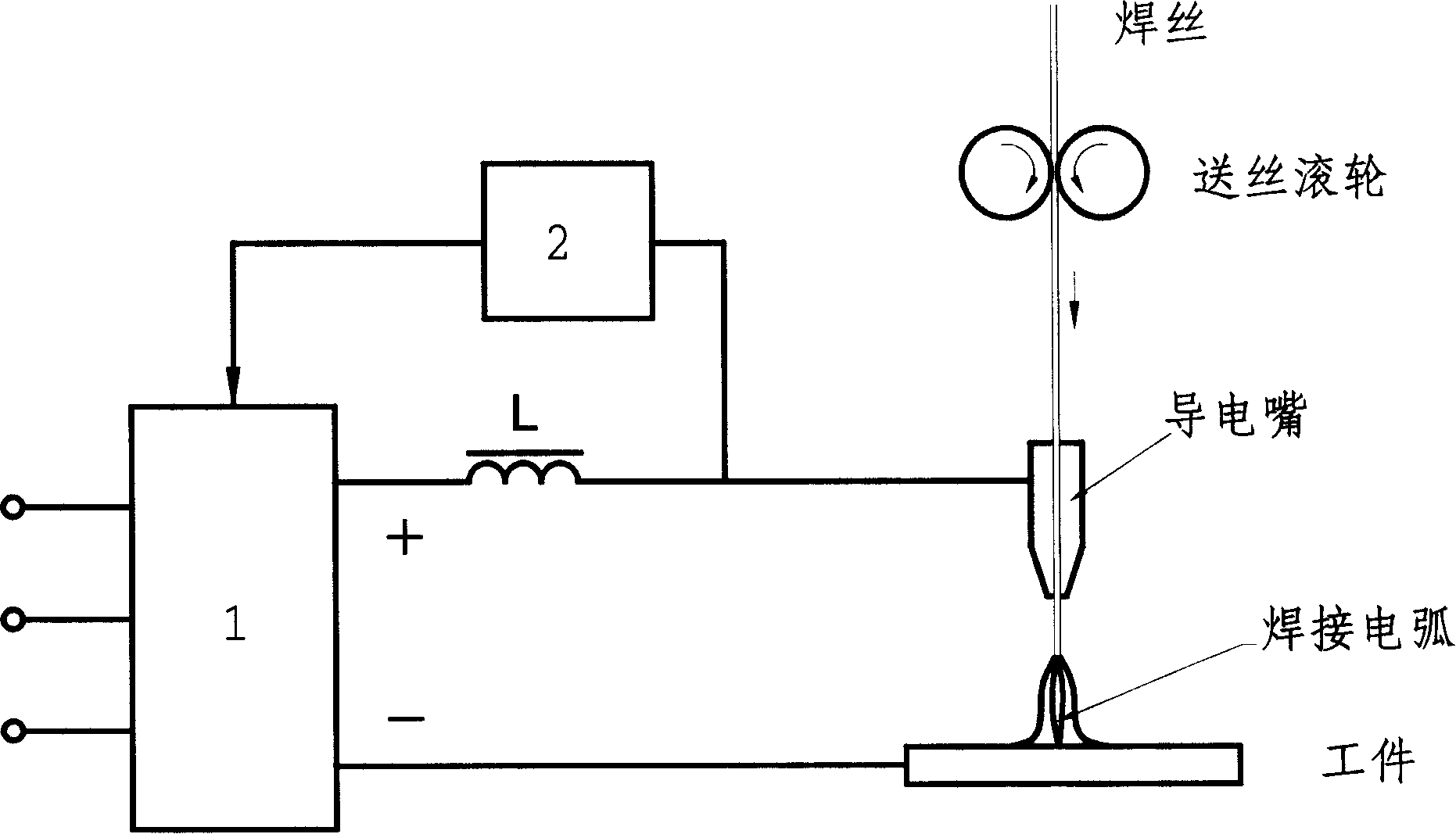

[0008] exist figure 1 Among them, the positive pole of the gas shielded welding power supply 1 is output through a DC reactor and connected to the contact tip. The negative output of the welding power supply is connected to the workpiece to be welded. The welding wire is fed forward by the roller, and the welding wire is positively charged through the conductive tip, and the welding arc is generated after the welding wire touches the workpiece. The welding arc state detection device 2 feeds back the detection results to the control system of the welding power source 1 .

[0009] The present invention is achieved through the following technical solutions:

[0010] A method of gas shielded welding for improving arc self-adjustment performance and preventing welding wire from burning back, CO 2 During the gas shielded welding process, through the welding arc state detection device 2, the change of the arc voltage during each arc burning period is detected in real time, the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com