Gas engine

A gas engine and gas technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of single air intake, compression, combustion and exhaust functions, uneven mixing of gas and combustion-supporting air, and reduce the working efficiency of gas engines. Efficiency and other issues, to achieve the effect of good start-up performance, good sealing performance, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

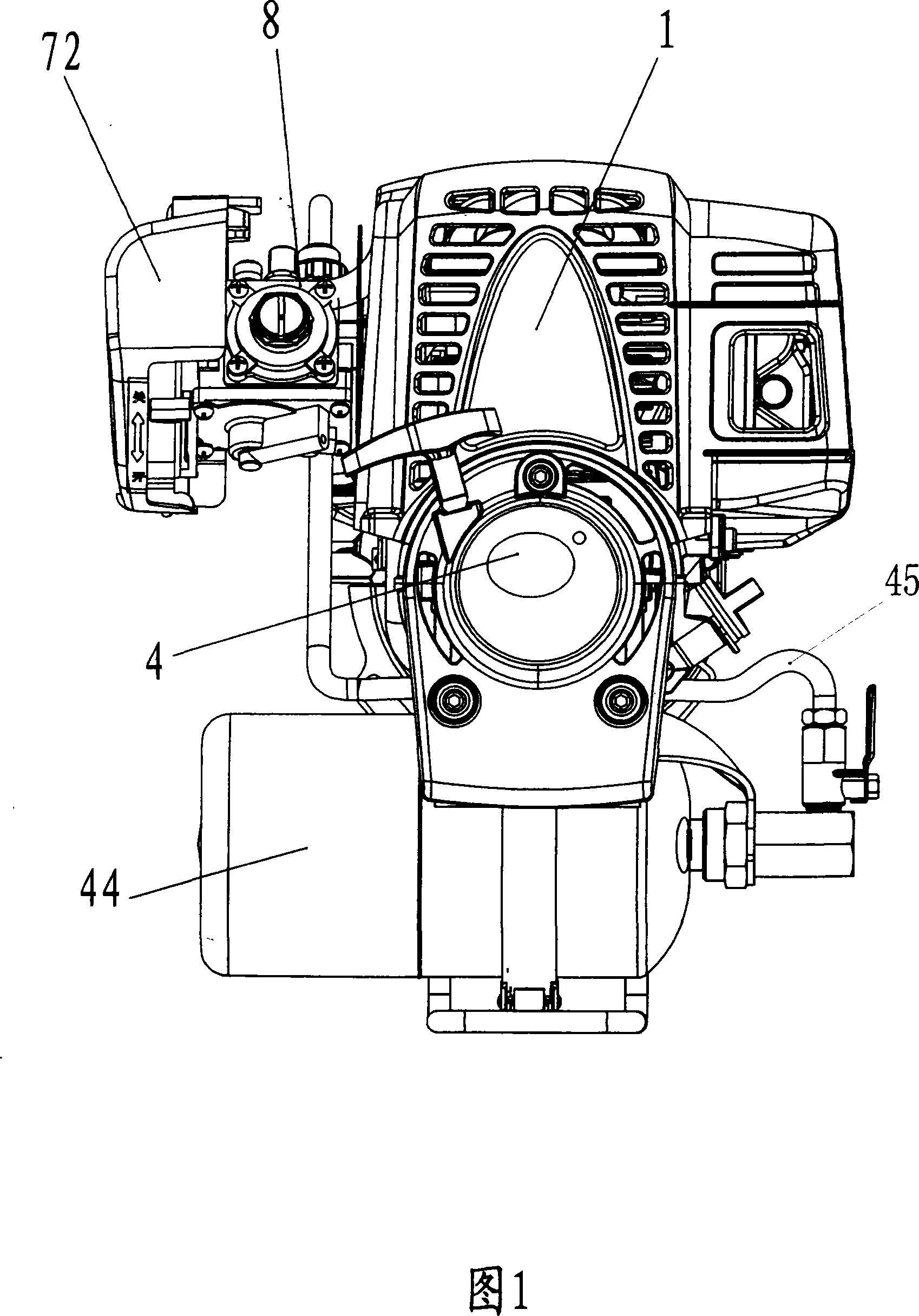

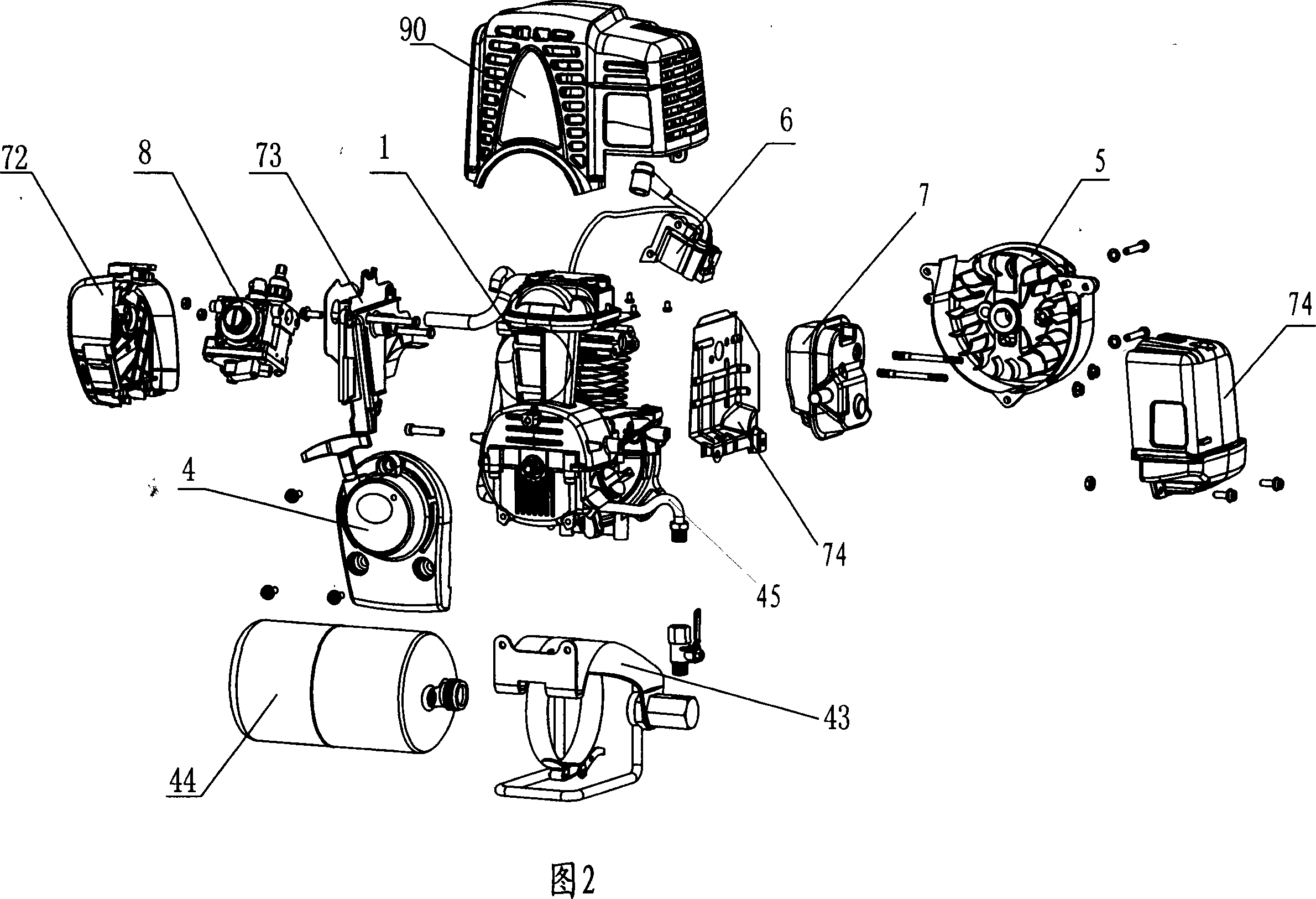

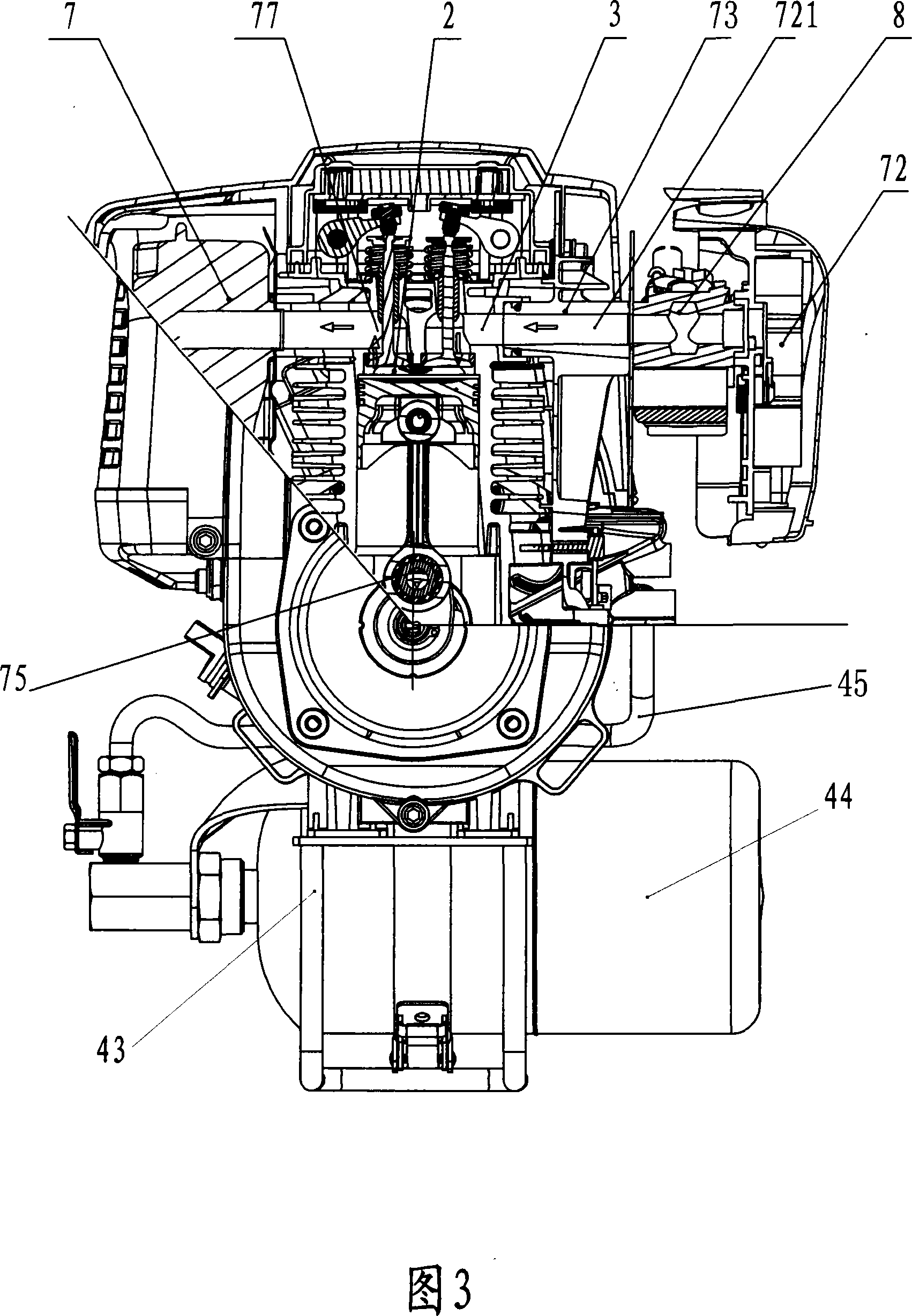

[0038] As shown in Figures 1 to 3, a gas engine includes an organic body 1, a protective cover 90 is set on the body 1, a combustion chamber 2 is provided in the body 1, and a mixing chamber that can communicate with the combustion chamber 2 is provided on the body 1. Gas inlet 3 and exhaust port 77; body 1 is also provided with starter 4 connected to crankshaft 75 in body 1 and magneto 5, igniter 6 connected with magneto 5, muffler connected with exhaust port 77 7. The muffler 7 is provided with a muffler cover 74; the mixed gas inlet 3 is sealed and connected with an air inlet joint 73, and the air inlet joint 73 is provided with a gas passage 721 leading to the mixed gas inlet 3, and the air inlet joint 73 The upper seal is connected with a controller 8 that can decompress the high-pressure gas and mix the decompressed low-pressure gas with air.

[0039] As shown in Figures 4 and 5, the controller 8 includes a housing 801 composed of a lower cover 81, an upper seat 82 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com