Friction -type full-automatic high speed main shaft on-line dynamic balance system and its control method

A high-speed spindle, fully automatic technology, used in static/dynamic balance testing, measuring devices, instruments, etc., can solve problems such as poor stability, low precision, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

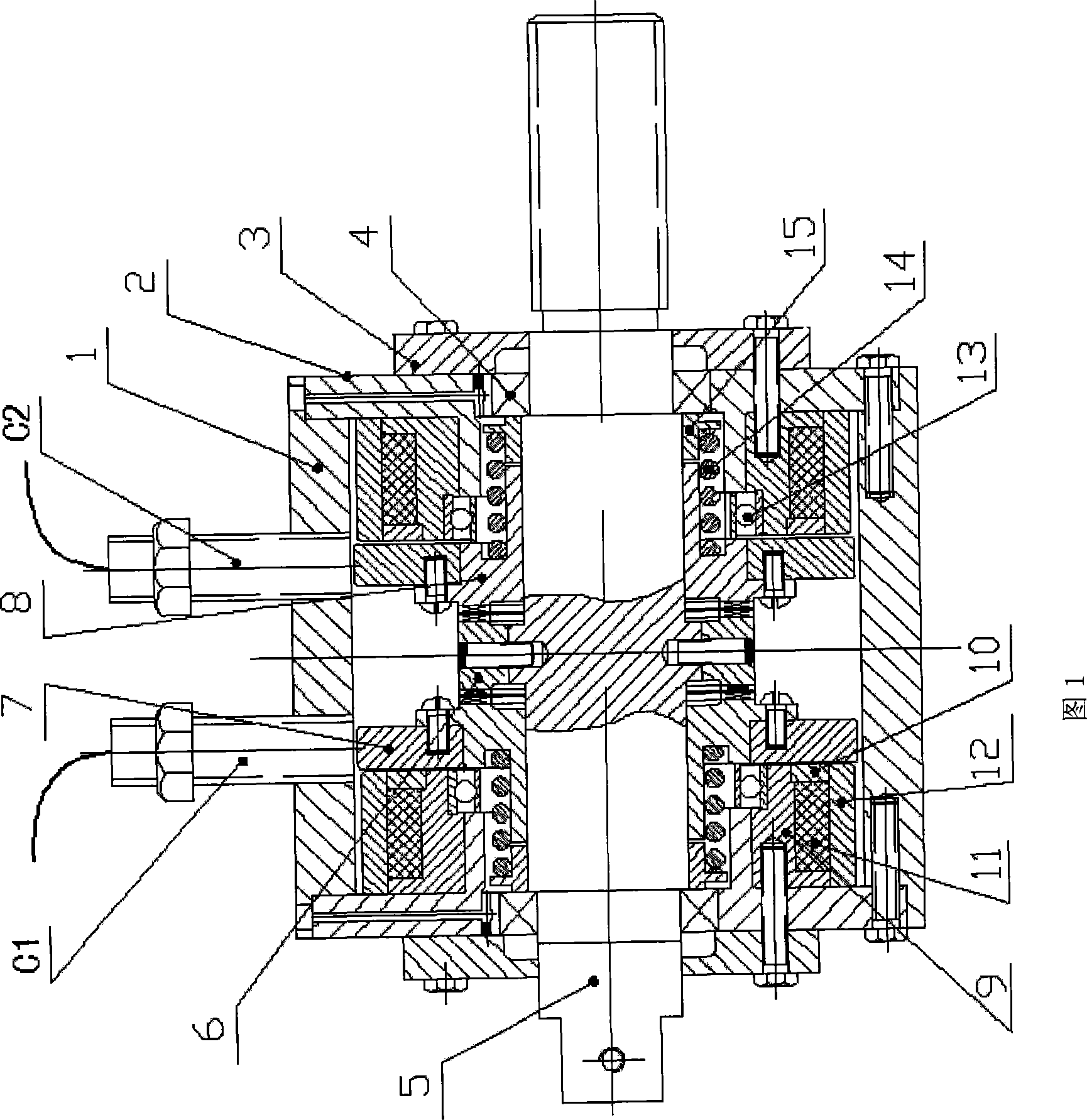

[0070] This embodiment is described in detail in conjunction with accompanying drawings 1 to 17

[0071] The invention mainly includes two parts: the mechanical structure of the balance head and the control system.

[0072] (1) Balance head mechanical structure

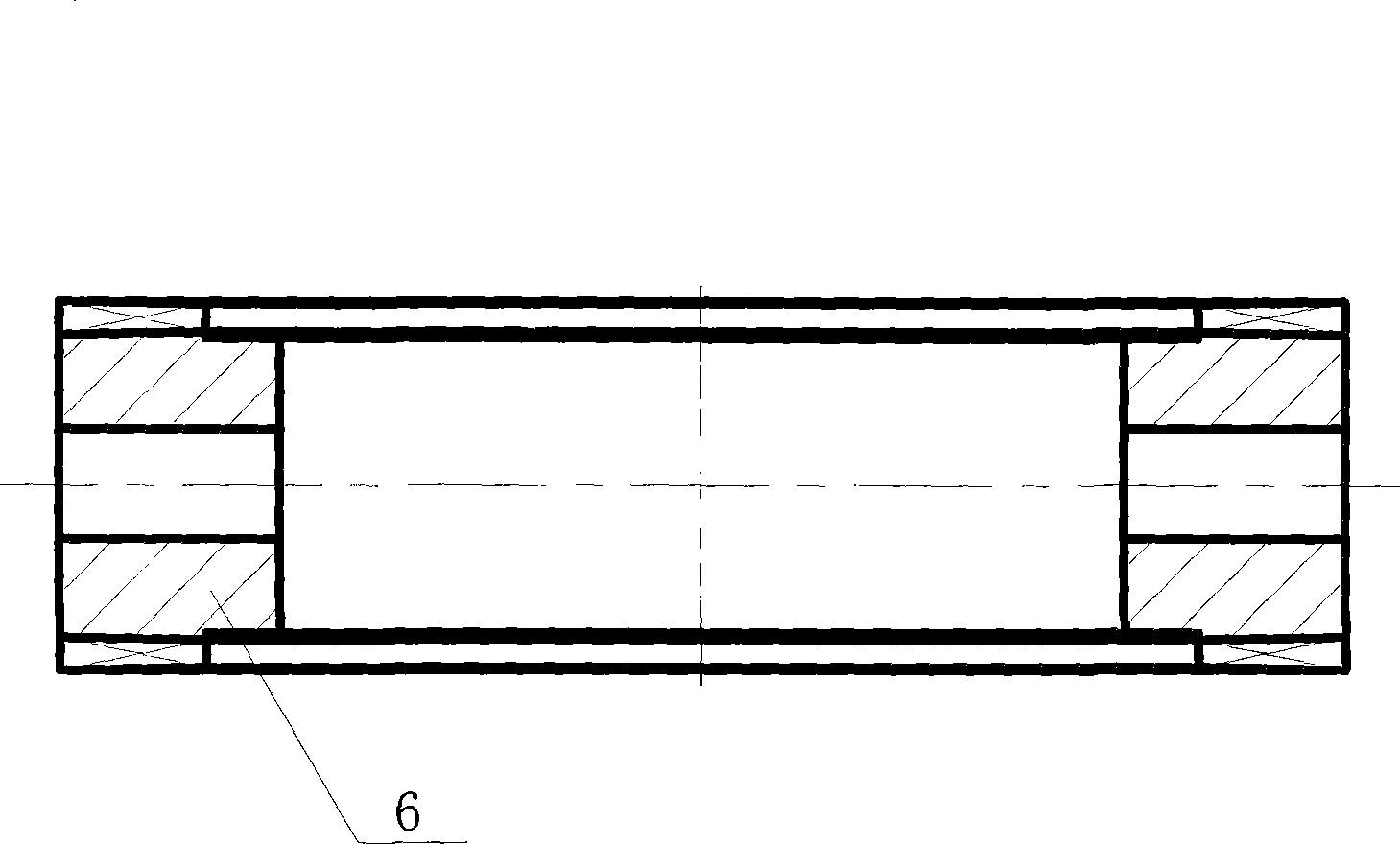

[0073] Figure 1 is the overall assembly diagram of the mechanical structure of the balance head. The balance head adopts a symmetrical structure design as a whole, and is symmetrical with the meshing ring gear 6 as the center. It includes four parts: the casing, the connecting shaft, the balance ring and the balance ring driving actuator, of which:

[0074] The shell includes a bearing 4 and a cylindrical shell 1 made of magnetic isolation material, a dome-shaped end cap 2 and a dome-shaped bearing cap 3, and each of the end cap 2, bearing cap 3 and bearing 4 has two symmetrical , the shell 1, the end cover 2 and the bearing cover 3 are fastened together;

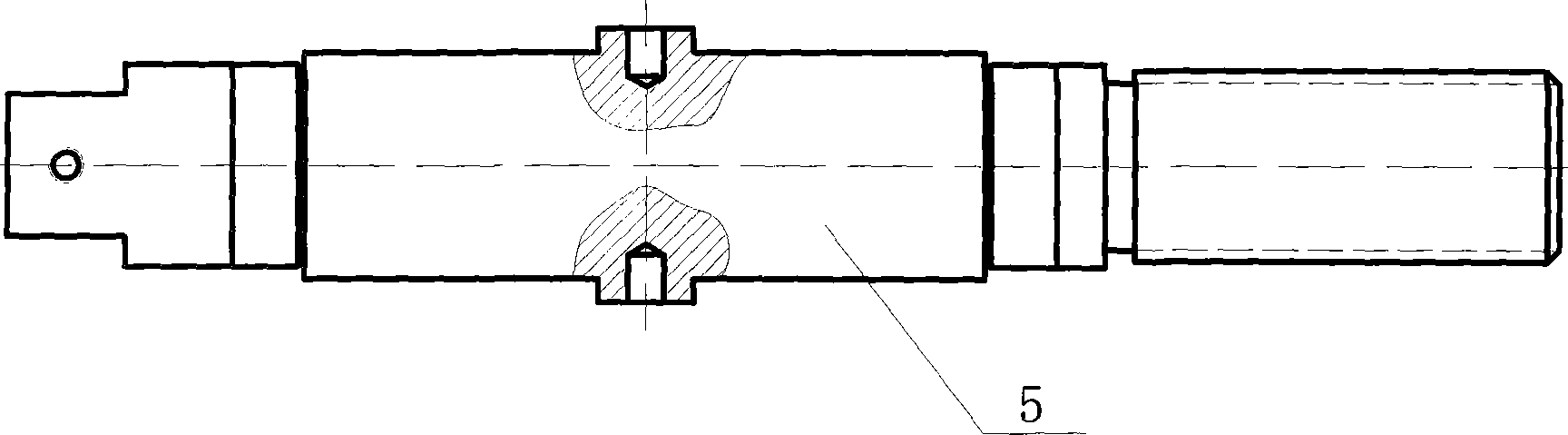

[0075] The connecting shaft includes a central shaft 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com