Device manufacturing method, laser processing method, and laser processing apparatus

A technology of laser processing and manufacturing methods, applied to laser welding equipment, lasers, measuring devices, etc., to achieve the effect of precise movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

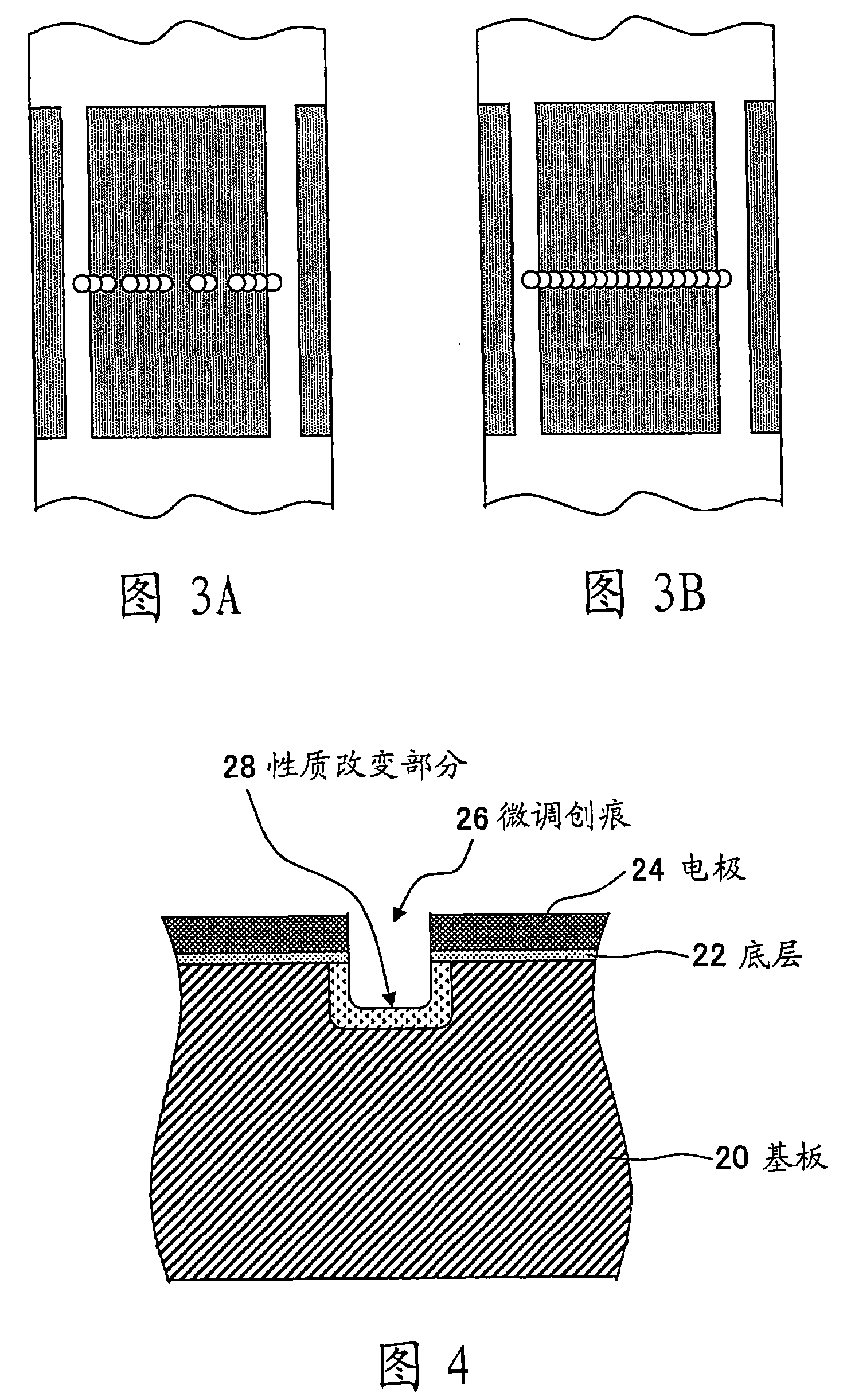

[0035] First, the principle of a laser processing method according to an embodiment of the present invention will be described with reference to FIGS. 2 to 4 .

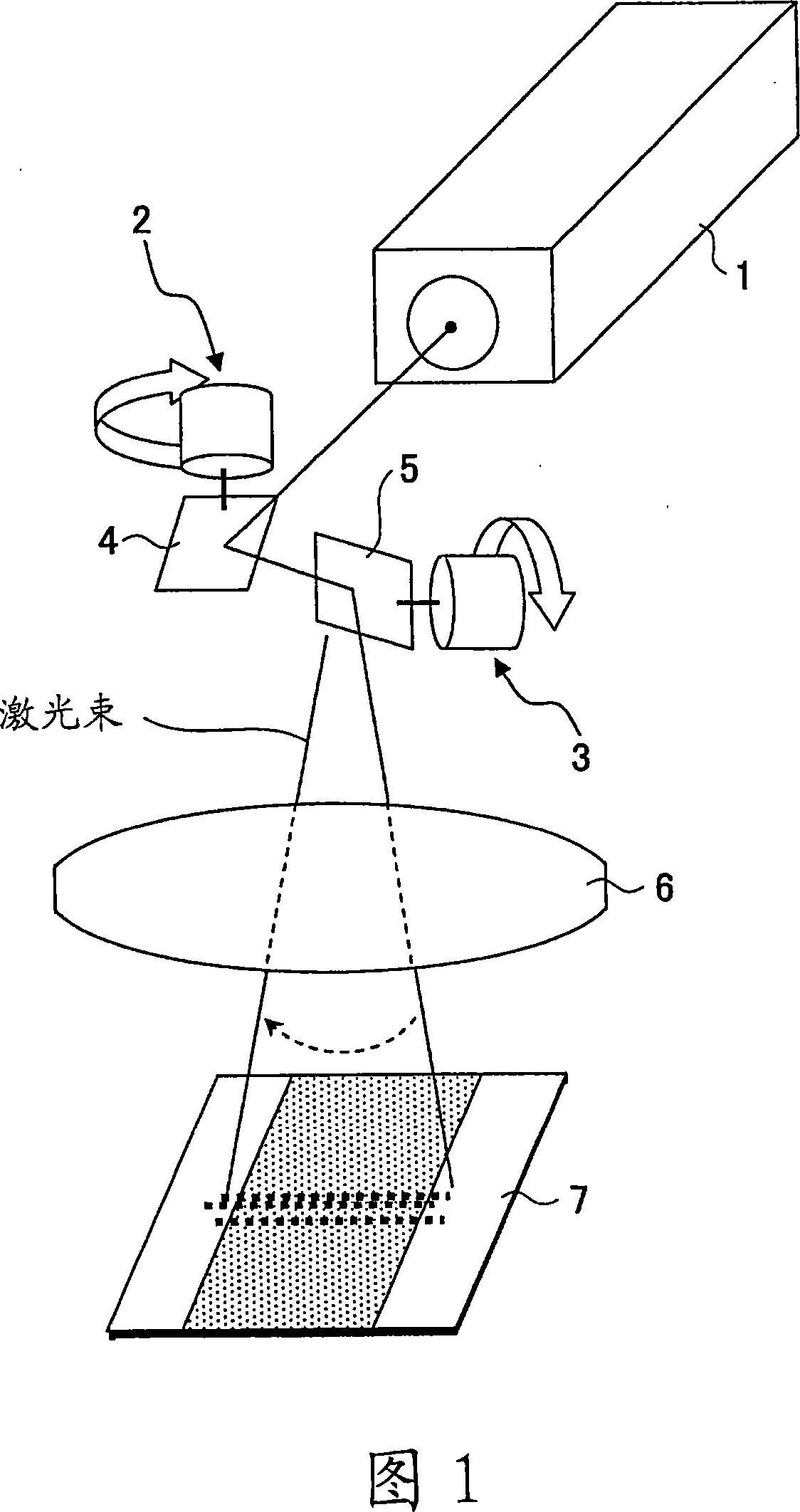

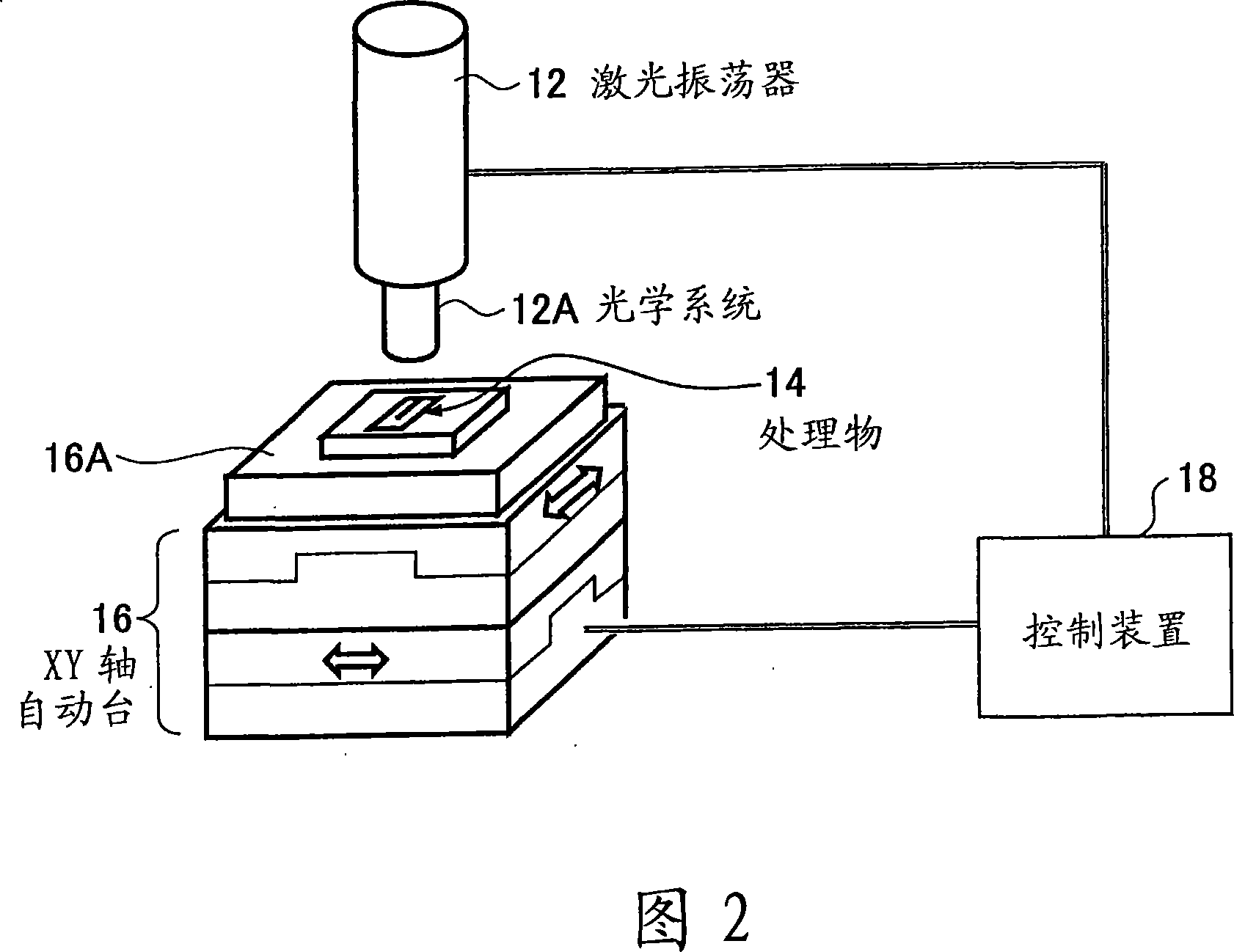

[0036] FIG. 2 is a diagram illustrating a laser processing apparatus performing a laser processing method according to an embodiment of the present invention.

[0037] The laser processing apparatus illustrated in FIG. 2 is particularly suitable for processing parts of small devices, and includes a laser oscillator 12 that oscillates a laser beam and an XY-axis automatic table 16 that holds a processing object (workpiece) 14 in place. It should be noted that the operations of the laser oscillator 12 and the XY-axis automatic table 16 are controlled by the control device 18 .

[0038]The laser oscillator 12 may be a laser such as a YAG laser, which oscillates a relatively high-power laser beam t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com