Laser process testing method and special instrument

A detection method and laser processing technology, applied in the direction of instruments, scientific instruments, laser welding equipment, etc., can solve the problems of complex process, low efficiency, inaccurate temperature detection in the processing area, etc., and achieve the effect of simple method and equipment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

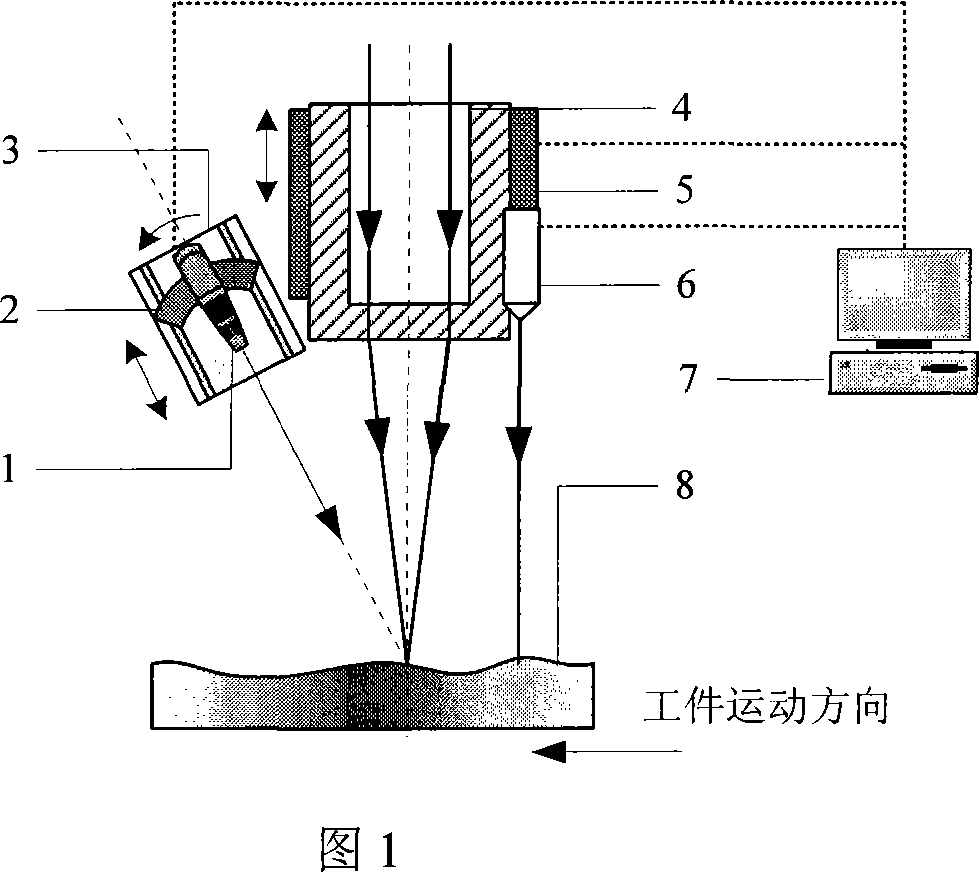

[0022] Referring to the attached picture:

[0023] The laser processing detection method of the present invention comprises the following steps:

[0024] 1. The non-contact rangefinder pre-measures the flatness change data of the workpiece surface to be processed;

[0025] 2. According to the flatness change data of the surface to be processed, the mobile platform dynamically adjusts the positions of the laser focusing head and the infrared thermometer to ensure that the laser focusing head, the infrared thermometer focusing head and the molten pool maintain a constant focal length;

[0026] 3. Make the swing platform drive the thermometer to do a dynamic plane scan in the molten pool area, re-calibrate the center of the molten pool, make the focus and sampling point of the thermometer follow the offset of the molten pool center, and ensure the authenticity of temperature measurement.

[0027] The special instrument of the laser processing detection method of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com