Method for preparing high-purity anhydrous formic acid from inorganic acid acidification formate

A technology of inorganic acid and formate, which is applied in the chemical industry, can solve the problems of waste of resources, etc., and achieve the effects of economical, applicable and environmental protection, low production cost, and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

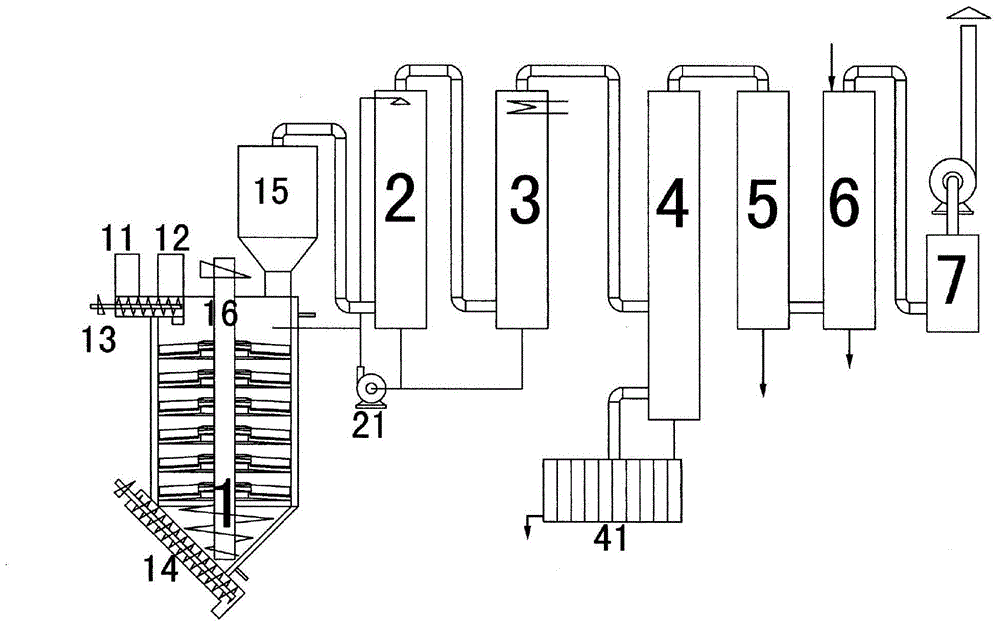

[0037]One device 1, φ1300×3500, and supporting devices 11, 12, 13, 14, 15, 16; one device 2, φ300×12000, and equipped with device 21; one device 3, φ300×12000; device 4 One set, φ300×15000, equipped with device 41, the number of stages is 18; one set of device 5, cooling area 20M2; one set of device 6, 500×500×5000, 20 stages, 5Kg / h of pure water. It is connected as figure 1 shown.

[0038] The absorption liquid in the device-2 is 80% formic acid, 3% trisodium phosphate, and 17% water.

[0039] With every batch of sodium formate (97%) 200Kg, 98% sulfuric acid 140Kg, every 20 minutes a batch of speed is dropped in device 1 by device 11 and 12 through 13, and the formic acid steam that reaction generates enters device 2, device successively after device 15 3, device 4, device 5, device 6, discharge the formic acid of content 79.5% in device 41, flow rate 47Kg / h. Discharge the high-purity anhydrous formic acid of content 99.85% at the bottom of device 5, flow 291Kg / h. Dischar...

Embodiment 2

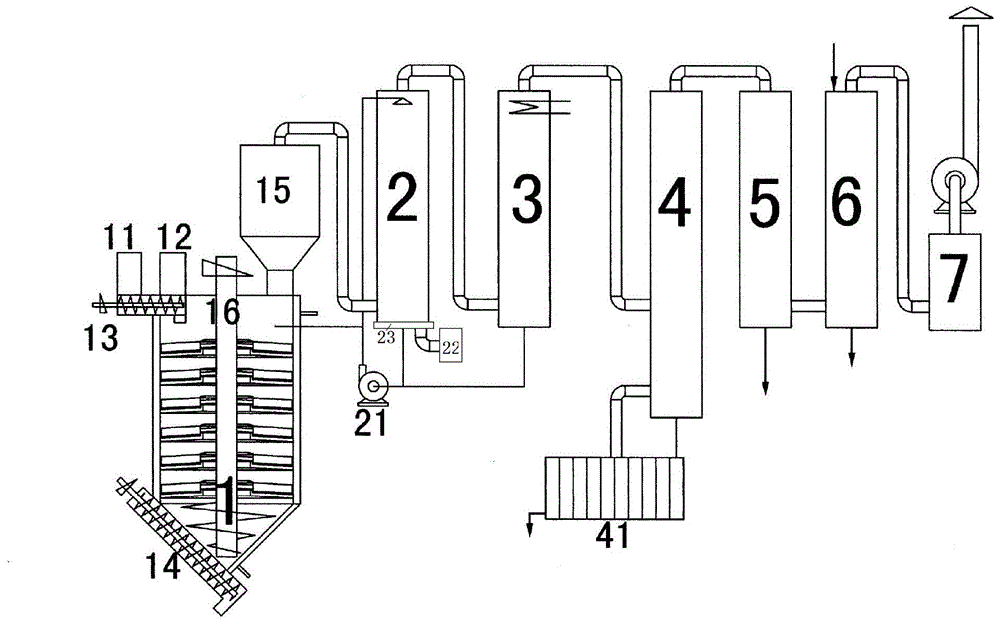

[0041] One set of device 1, φ1300×3500, and supporting devices 11, 12, 13, 14, 15, 16; one set of device 2, φ300×12000, and equipped with devices 21, 22, 23, the absorption liquid is 78% formic acid , 5% sodium tripolyphosphate, 17% water; one device 3, φ300×12000; one device 4, φ300×15000, and equipped with device 41, the number of stages is 18; one device 5, cooling The area is 20M2; 6 devices, 500×500×5000, 20 grades, 5Kg / h of pure water. It is connected as figure 2 shown.

[0042] With every batch of sodium formate (97%) 200Kg, 98% phosphoric acid 285Kg, every 20 minutes a batch of speed is dropped in device 1 by device 11 and 12 through 13, and the formic acid steam that reaction generates enters device 2, device successively after device 15 3. Device 4, Device 5, Device 6. Discharge the formic acid of content 79.5% in device 41, flow rate 59Kg / h. Discharge the high-purity anhydrous formic acid of content 99.97% at the bottom of device 5, flow 295Kg / h. Discharge con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com