Process and testing method for PCB drilling machine drill chuck

A detection method, drilling machine technology, applied in the direction of metal processing equipment, grinding machine parts, manufacturing tools, etc., to achieve the effect of easy operation and control, meeting design and production requirements, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are further explanations and descriptions of the present invention, and do not constitute any limitation to the present invention.

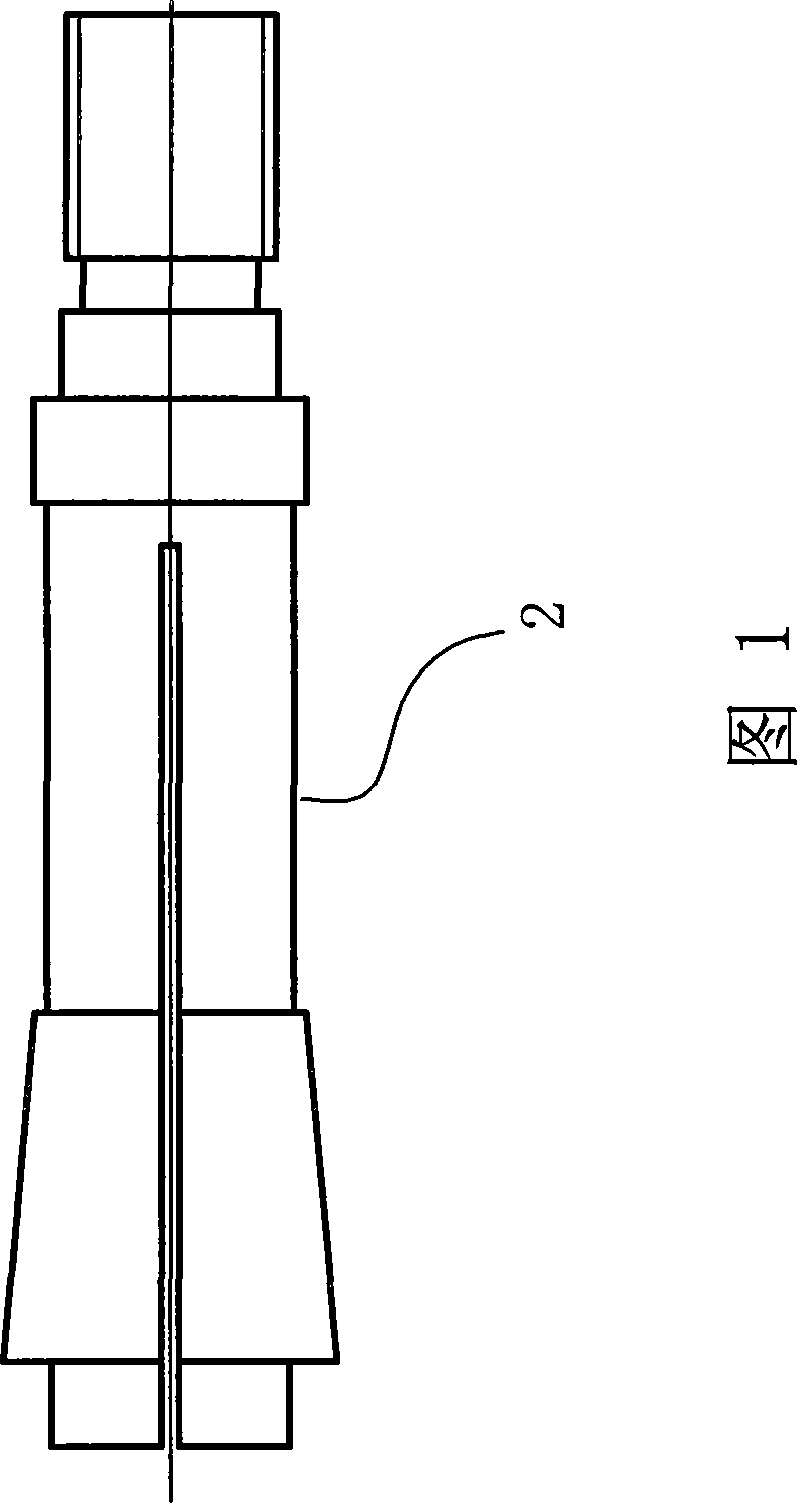

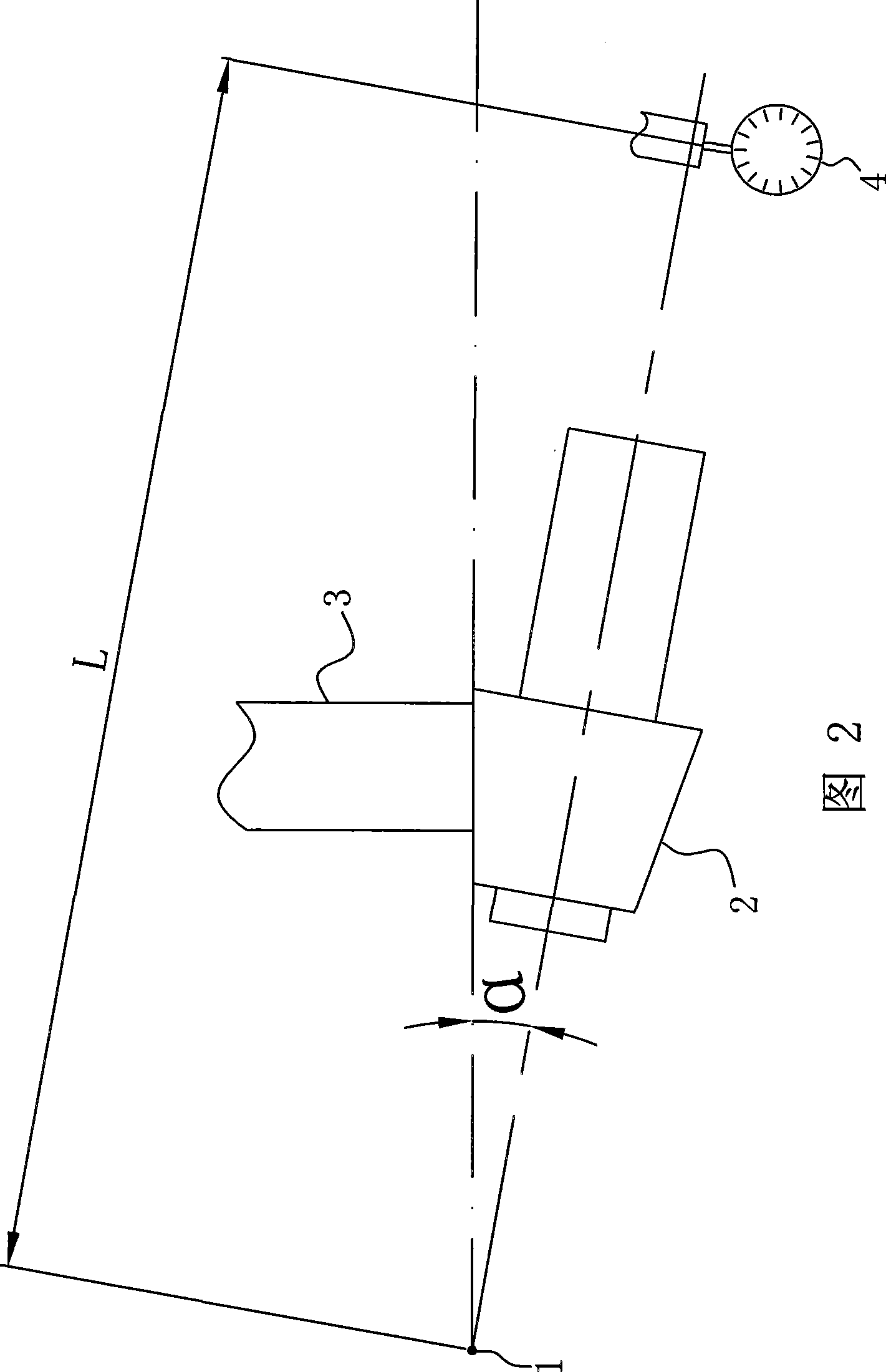

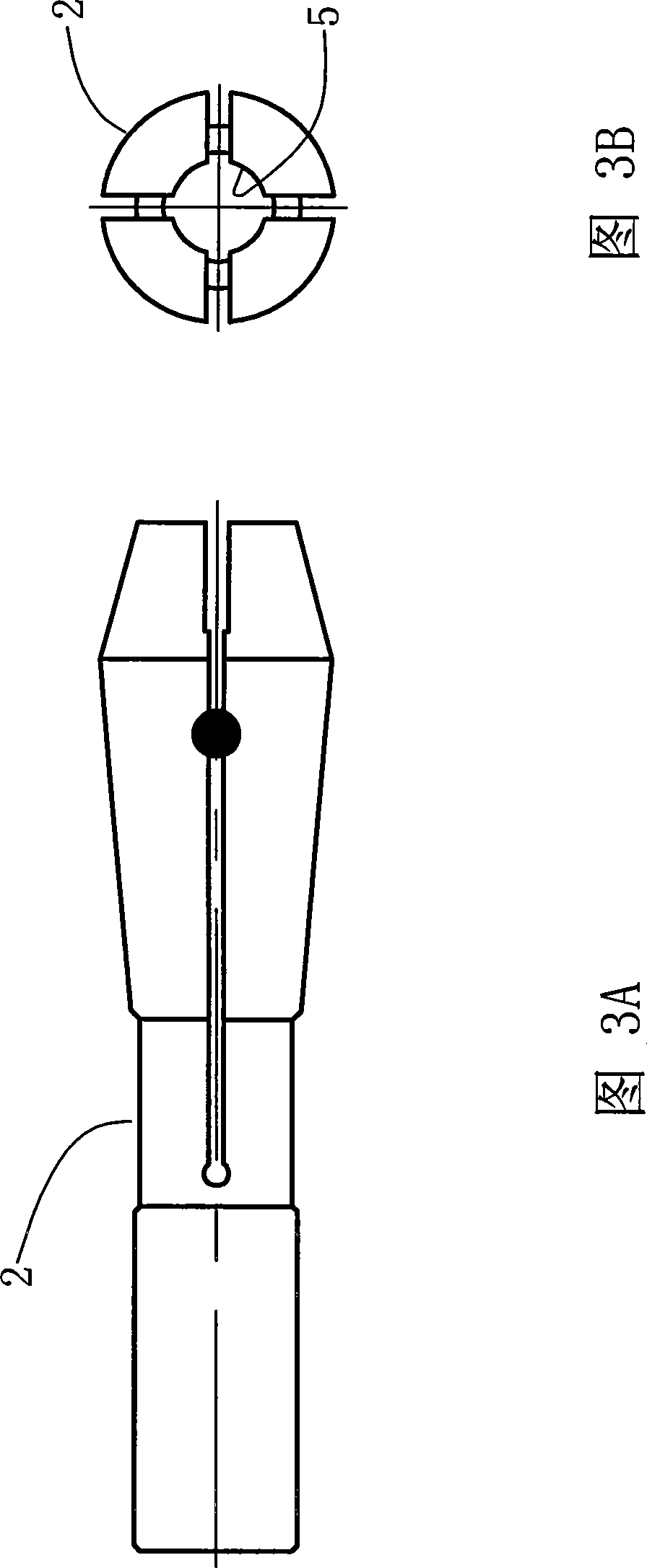

[0016] The invention provides a method for processing and detecting a drill chuck of a PCB drilling machine. The method includes the following steps:

[0017] 1. To control the straightness of the external conical bus of the chuck and the roundness of the cylindrical surface, the specific steps are as follows:

[0018] Use a commercially available cylindrical grinder, such as a precision closed-loop CNC grinder from Studer, Switzerland, to grind the outer conical surface and outer cylindrical surface of the chuck. The grinding wheel spindle of the machine tool has a runout accuracy of 0.016 microns and is supported by a hydraulic floating bearing. The centering of the spindle realizes precision sensing closed-loop numerical control, with the most intuitive large screen display, high stability, and large margin for precis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com