Environment-friendly infrared frequency multiplication sulfureous series vitro-ceramic and preparation thereof

An environment-friendly chalcogenide glass technology, applied in the field of nonlinear optical glass-ceramic materials, can solve the problems of glass transition temperature and hardness and other thermodynamic performance degradation, physical and chemical properties, water resistance degradation, etc., to achieve the improvement and reduction of nonlinear optical performance Effects of scattering loss and stabilization of physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

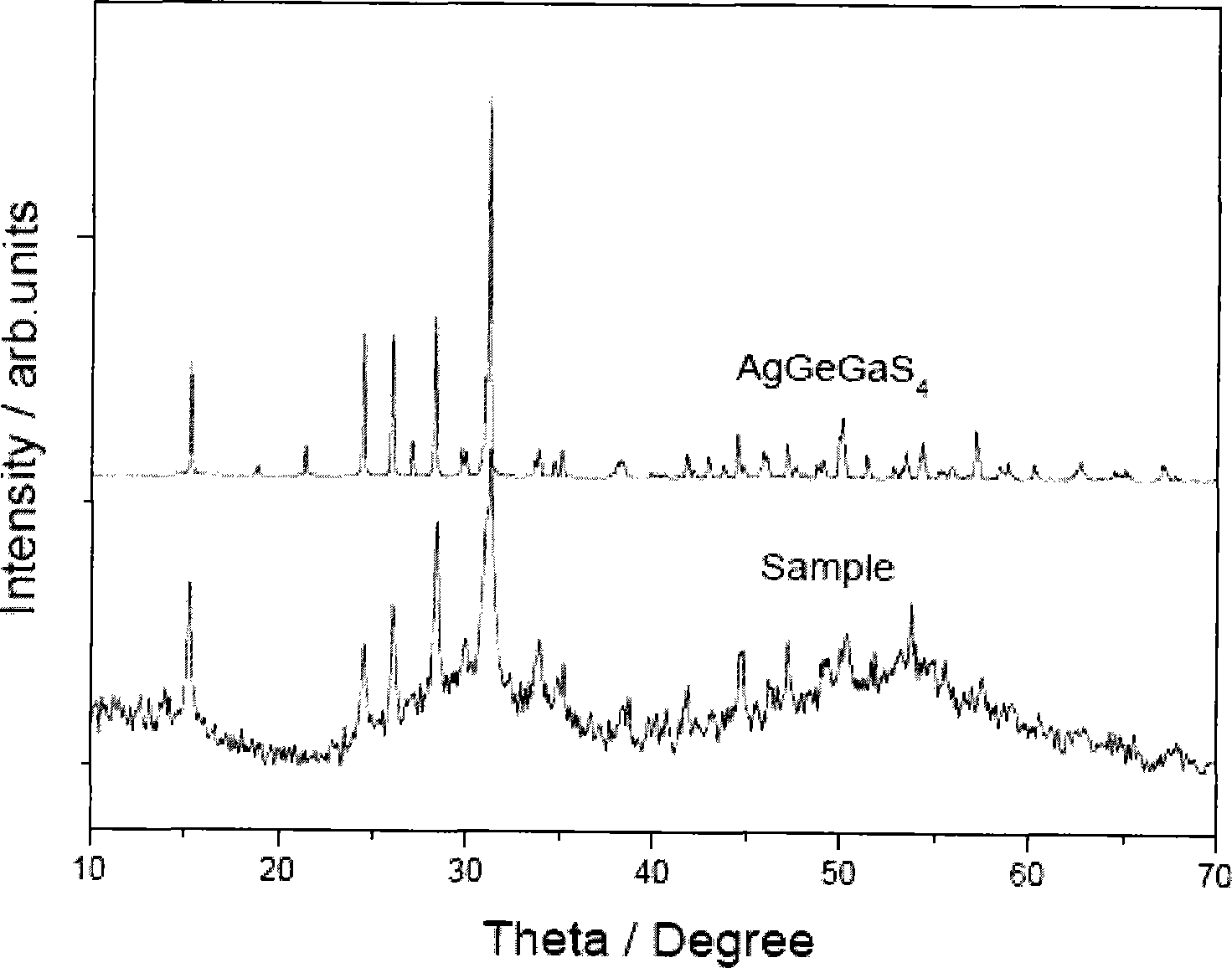

Image

Examples

Embodiment 1

[0032] An environment-friendly infrared frequency-doubling chalcogenide glass-ceramic, its composition can be expressed as: 64%GeS 2 36%AgGaS 2 , 64%, and 36% are the molar percentages of each compound.

[0033] The specific preparation method is as follows:

[0034] 1). Select raw materials: according to 64% GeS 2 36%AgGaS 2 , 64%, and 36% are the molar percentages of each compound, select elemental Ge, Ga, Ag and S raw materials for subsequent use, and the purity of each elemental substance is ≥99.99% (mass) respectively;

[0035] 2). Filled with inert gas (such as N 2 ) environment, the elemental Ge, Ga, Ag and S raw materials are mixed, and after grinding and mixing to make batches, they are placed in a container and vacuumed, and the vacuum degree is 10 -5 Pa, then seal the container and place it in a heating device;

[0036] 3). Preparation of basic glass: heat the container containing the batch material in step 2), first slowly (heating rate is less than 3°C / min) ...

Embodiment 2

[0040] An environment-friendly infrared frequency-doubling chalcogenide glass-ceramic, its composition can be expressed according to the chemical formula (the chemical composition formula of the basic glass): 95% GeS 2 5%AgGaS 2 , 95%, 5% are the molar percentages of each compound.

[0041] The specific preparation method is as follows:

[0042] 1). Select raw materials: according to 95% GeS 2 5%AgGaS 2 , 95%, 5% are the molar percentages of each compound, select elemental Ge, Ga, Ag and S raw material for subsequent use, and the purity of each elemental substance is ≥99.99% (mass) respectively;

[0043] 2). Filled with inert gas (such as N 2 ) environment, the elemental Ge, Ga, Ag and S raw materials are mixed, and after grinding and mixing to make batches, they are placed in a container and vacuumed, and the vacuum degree is 10 -4 Pa, then seal the container and place it in a heating device;

[0044] 3). Preparation of basic glass: heat the container containing batch m...

Embodiment 3

[0048] An environment-friendly infrared frequency-doubling chalcogenide glass-ceramic, its composition can be expressed according to the chemical formula (the chemical composition formula of the basic glass): 50% GeS 2 50%AgGaS 2 , 50%, 50% are the mole percentage of each compound.

[0049] The specific preparation method is as follows:

[0050] 1). Select raw materials: according to 50% GeS 2 50%AgGaS 2 , 50%, 50% are the molar percentages of each compound, select elemental Ge, Ga, Ag and S raw material for subsequent use, and the purity of each elemental substance is ≥99.99% (mass) respectively;

[0051] 2).In an environment full of inert gas, mix the elemental Ge, Ga, Ag and S raw materials, grind and mix them to make batches, put them in a container and vacuumize, the vacuum degree is 10 -5 Pa, then seal the container and place it in a heating device;

[0052] 3). Preparation of the basic glass: heat the container containing the batch material in step 2), first slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com