Method for producing maotai-flavor flavoring wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

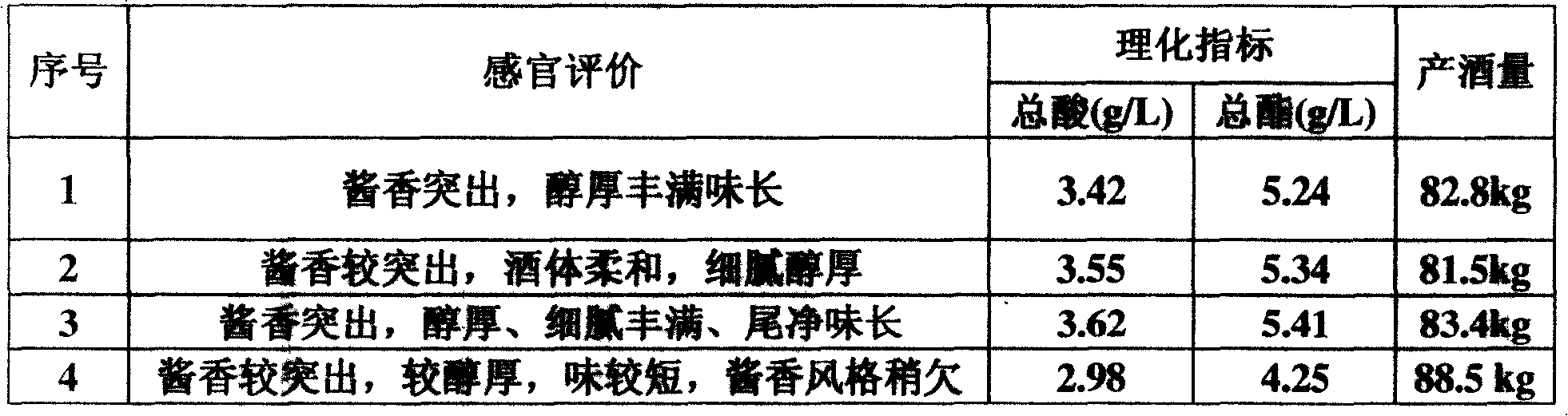

[0032]The preparation method flow process of Maotai flavor seasoning wine of the present invention is:

[0033] Take the high-quality cellar-bottom fermented grains or double-wheel bottom fermented grains (1600-1700 kg) that have not taken wine between four and six times, add 80-100 kg of high-temperature koji powder, 10 kg of cooked rice husks, mix well, and then add 100 kg of additive liquid. ~120kg (75~85 parts of yellow water, 0.4~0.6 parts of wine head, 8~9 parts of wine tail, 4~6 parts of ordinary sauce-flavored liquor cellar bottom grains, and 5~8 parts of cellar bottom mud. Alcohol concentration is controlled at 4 to 6%, sealed and stored for 2 to 4 months to obtain the additive used in the present invention) and quickly stirred evenly. After the fermented grains are put into the pool, they are manually smoothed and then patted tightly, and 1-2kg of cooked rice husks are evenly sprinkled on it or marked with a grate, and then the prepared sauce-flavored and seasoned di...

Embodiment 1

[0038] Embodiment one: the inventive method prepares sauce-flavored seasoning wine

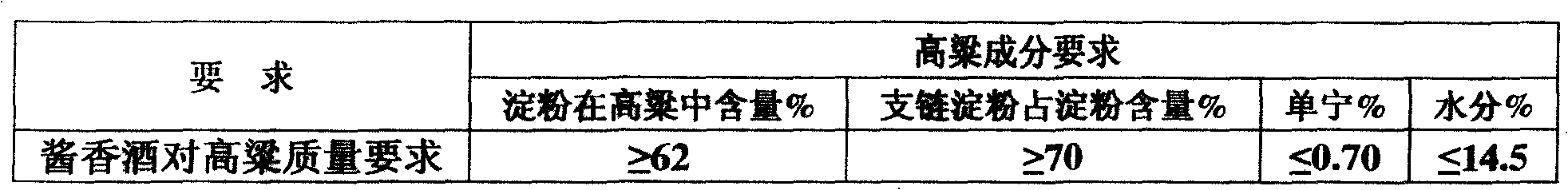

[0039] Prepare Maotai-flavored liquor by above-mentioned routine Maotai-flavored liquor production technique, get 4 parts of the third bottom dregs in the production process, every part of 1700kg, wherein three parts are produced Maotai-flavored seasoning wine by the method of the present invention, and a part is by existing method Prepare the sauce-flavored seasoning wine (the amount of raw materials in each group is shown in Table 3). Tasting, physical and chemical analysis and hygienic index detection were carried out on the prepared sauce-flavored seasoning wine:

[0040] 1. Sensory evaluation experiment of sauce-flavored seasoning wine

[0041] 1. Quality inspection basis for sensory evaluation: "Methods for Sensory Evaluation of Liquor" GB / T10345.2;

[0042] 2. Participants in wine evaluation: 10 people. Among them: 1 member of the National Liquor Expert Group; 3 members of the Nation...

Embodiment 2

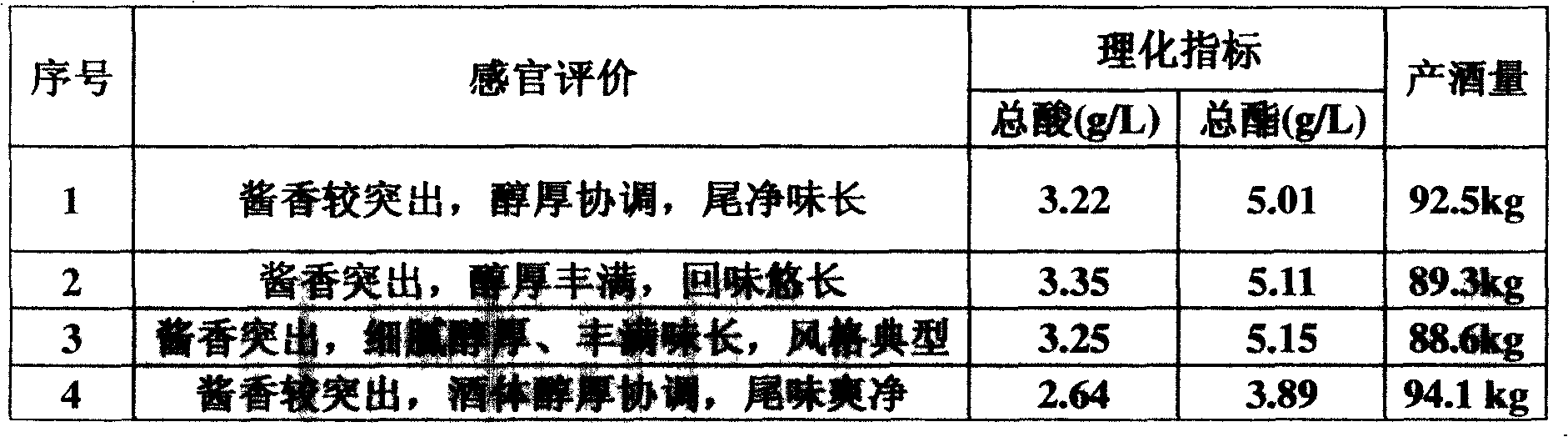

[0065] Embodiment two: the preparation of sauce-flavored seasoning wine of the present invention

[0066] Prepare Maotai-flavored liquor by above-mentioned routine Maotai-flavored liquor production technique, get 4 parts of the fifth bottom dregs in production process, every part 1600kg, wherein three parts are produced Maotai-flavored seasoning wine by the method of the present invention, one part is by existing method Prepare the sauce-flavored seasoning wine (see Table 4 for the dosage of each group of raw materials). Tasting, physical and chemical analysis and hygienic index detection were carried out on the prepared sauce-flavored seasoning wine:

[0067] 1. Sensory evaluation experiment of sauce-flavored seasoning wine

[0068] The tasting evaluation method was carried out according to the method in Example 1 "Sensory Tasting Experiment of Maotai-flavored Flavored Wine", and the tasting personnel were unchanged.

[0069] 2. Detection of physical and chemical indicators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com