Application of organosilicon surfactant in denim preshrunk and correlative device

A technology of surfactant and silicone, applied in the direction of spraying/spraying textile materials, etc., can solve the problems of poor stiffness and difficulty in integration, and achieve the effects of good ventilation, energy saving, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

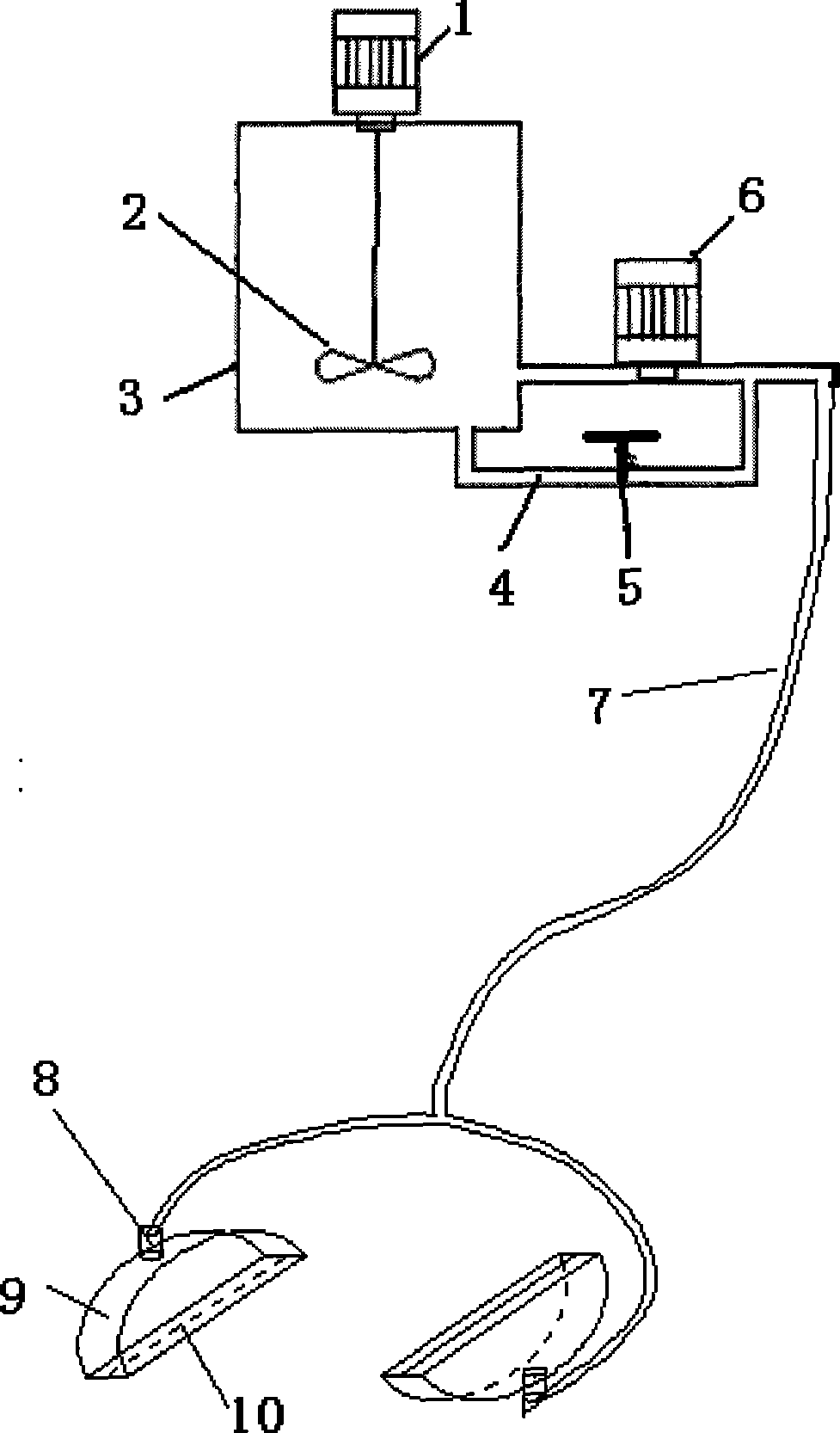

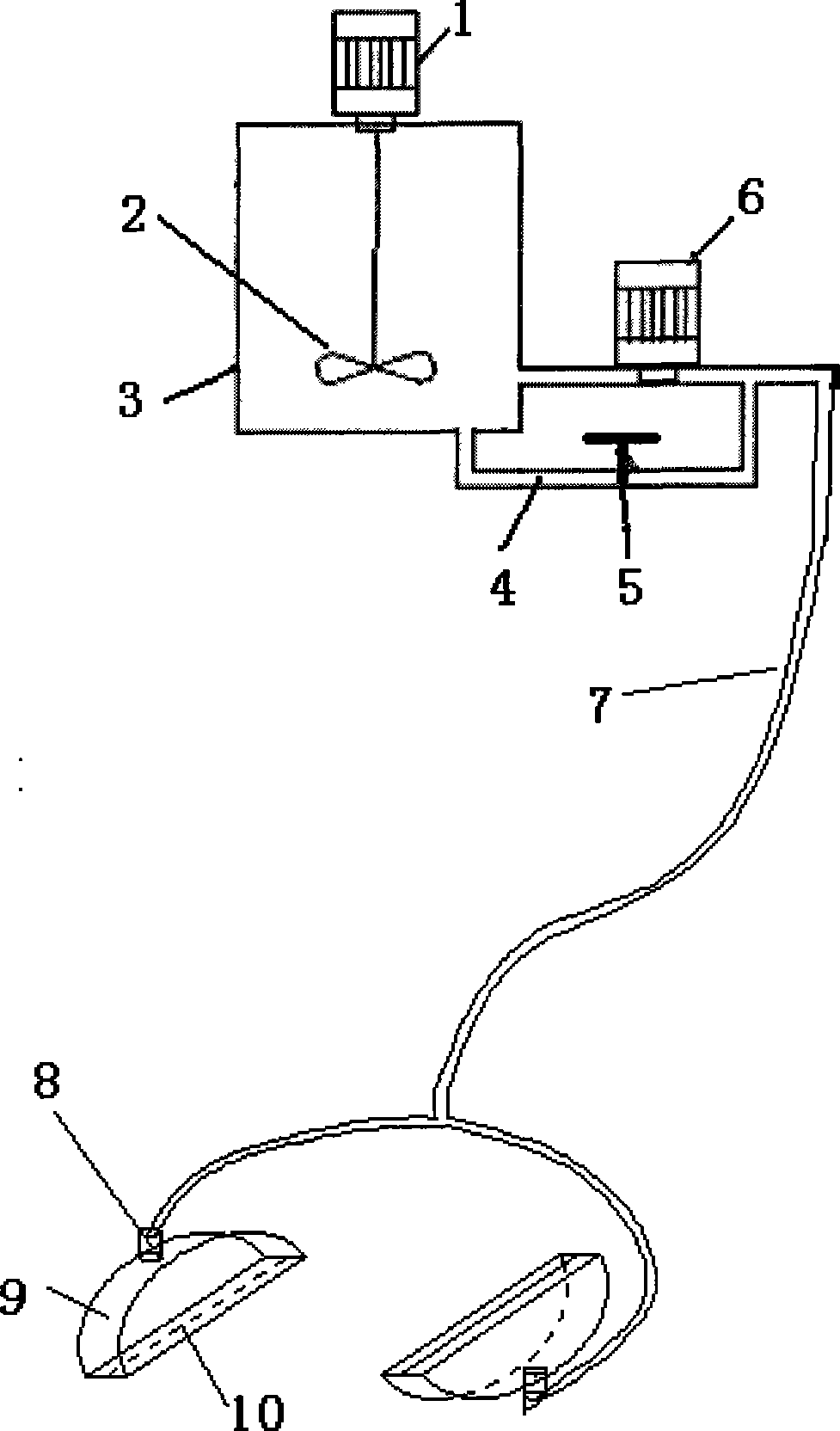

[0009] Wetting feeding device of the present invention has a stirrer 1, and its stirring vane 2 stretches in the mixing tank 3 that organosilicon surfactant aqueous solution is housed, and the side and the bottom of mixing tank 3 are connected with bypass pressure regulating pipe 4 Communication, the bypass pressure regulating pipe 4 is equipped with a booster pump 6 and a gate 5, and communicates with the input port 8 of the two injection heads 9 through the delivery pipeline 7, and the shell of the injection head 9 is made of stainless steel. The thick 50mm of box body, there is a slit 10 on the plane of jetting head 9 to contact with cloth surface when using, and the wide 1.5mm of slit 10 of jetting head 9, box body length depends on cloth surface.

[0010] Put the above-mentioned aqueous solution in the above-mentioned mixing tank 3 during use, the organosilicon surfactant has excellent wettability and defoaming property, and the hydrophobicity of its main component polysil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com