Combined steel plate shearing force wall with large aspect ratio

A steel plate shear wall, aspect ratio technology, applied in the direction of walls, building components, shockproof, etc., to achieve the effect of flexible layout, full hysteresis curve, and stable hysteresis curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

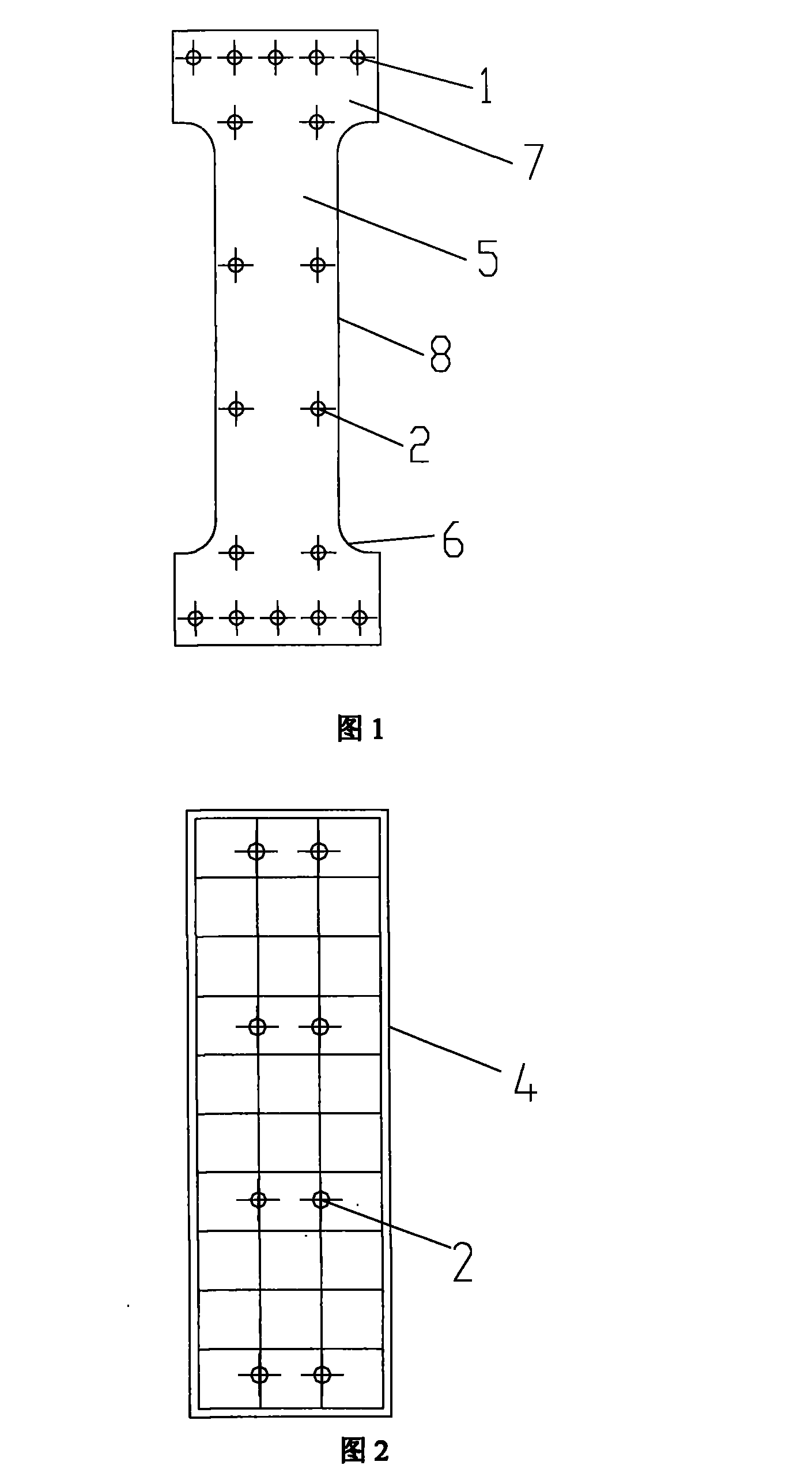

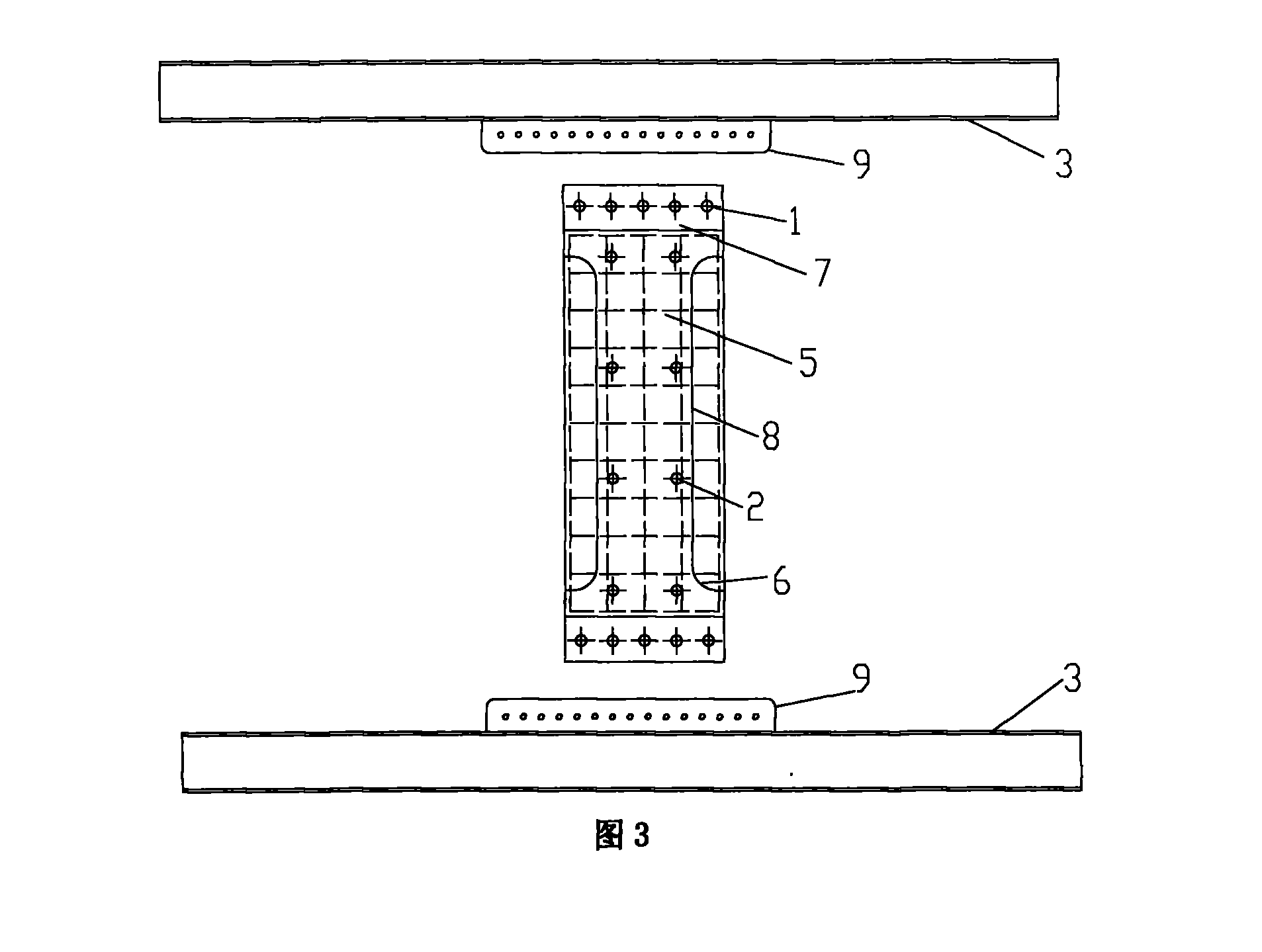

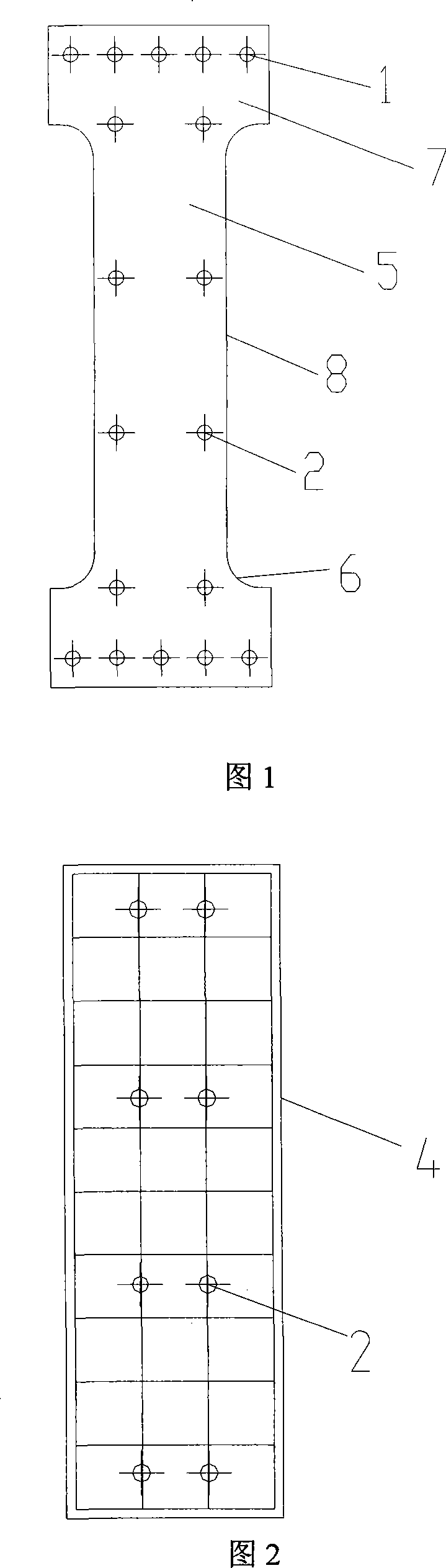

[0019] Embodiment 1: The high aspect ratio combined steel plate shear wall of the present invention is composed of steel plate 5 and concrete plate 4; the high aspect ratio steel plate 5 adopts ordinary structural steel, and the concrete plate 4 adopts prefabricated concrete plate, and the high aspect ratio The steel plate 5 is connected to the frame beam 3 through high-strength friction bolts 1, and the concrete slab 4 is connected to the steel plate 5 with a large aspect ratio through ordinary bolts 2. By weakening the middle part of the steel plate 5 with a large aspect ratio, the yield section is moved down to ensure the It has good ductility, and prevents stress concentration of components through the arc transition zone 6.

[0020] In order to verify the performance of this product, a test piece was made for research, mainly to investigate the performance of the steel plate wall with large aspect ratio.

[0021] The high aspect ratio steel plate 5 of the test piece is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com