Bearing sealing device

A bearing sealing and bearing technology, which is used in the sealing of engines, components of pumping devices for elastic fluids, and non-variable-capacity pumps, can solve problems such as expensive users, and achieve lubricant leakage control and performance. The effect of stability and pollution source control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

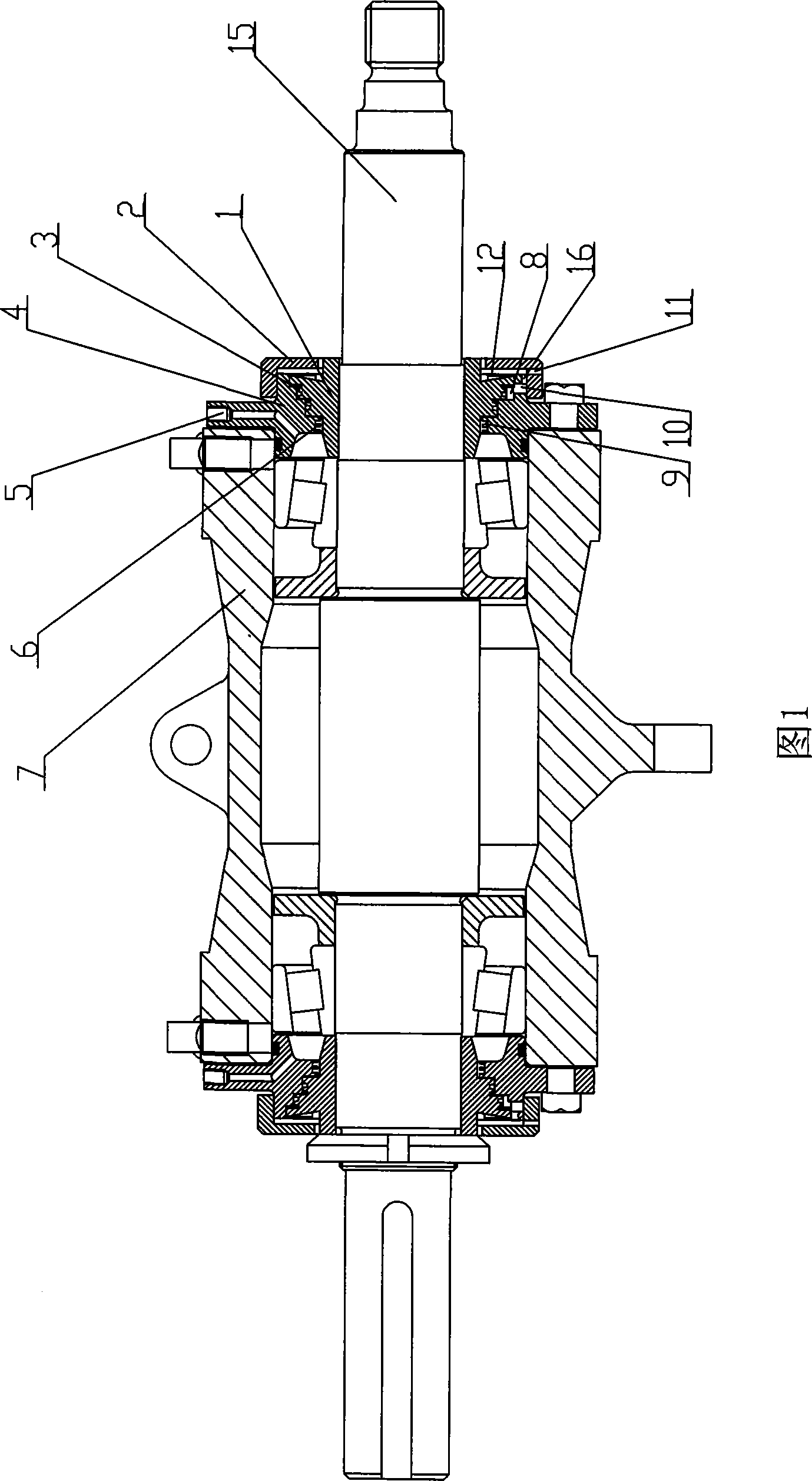

[0020] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

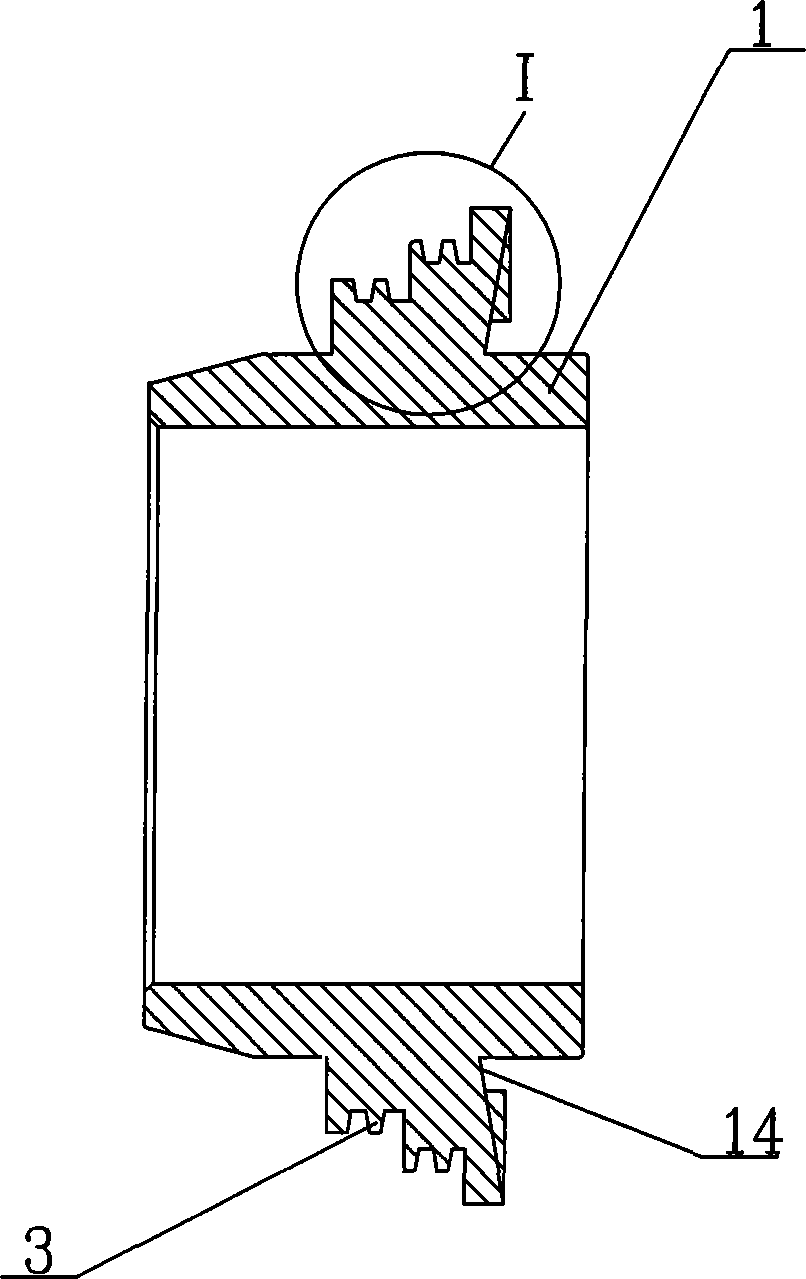

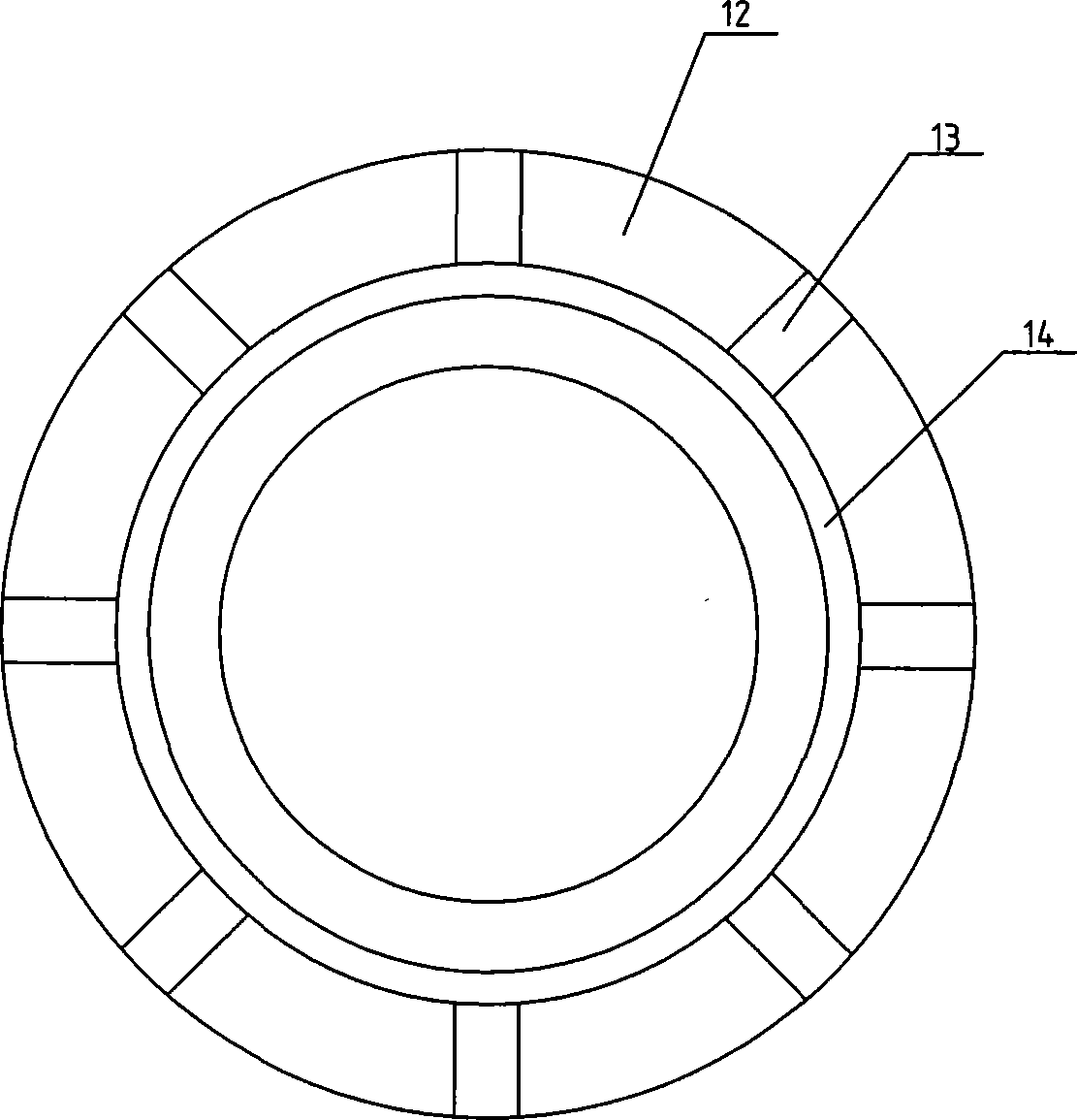

[0021] It can be seen from Figure 1 that the end cover 4 is connected to the bearing body 7 by bolts, the bearing positioning sleeve 1 is sleeved on the shaft 15. The outer cylindrical surface of the bearing positioning sleeve 1 has a stepped concentric cylindrical surface, and a labyrinth ring is provided on the concentric cylindrical surface The groove 3 and the end cover 4 have a stepped concentric inner cylindrical surface matched with the bearing positioning sleeve 1. From Figure 1, Figure 5 with Figure 6 It can be seen that there is a leakage hole I10 on the outer inner cylindrical surface of the end cover 4, which is located directly below the installation position of the end cover 4. The inner cylindrical surface and the outer cylindrical surface of this cylinder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com