Novel pulping method for hyperfine water-coal-slurry

An ultra-fine, coal-water slurry technology, which is applied in the direction of combustion methods, block/powder fuel preparation, combustion equipment, etc., can solve problems such as unreachable, energy waste, application limitations of coal-water slurry, etc., to reduce production costs, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A new ultra-fine coal-water slurry pulping method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

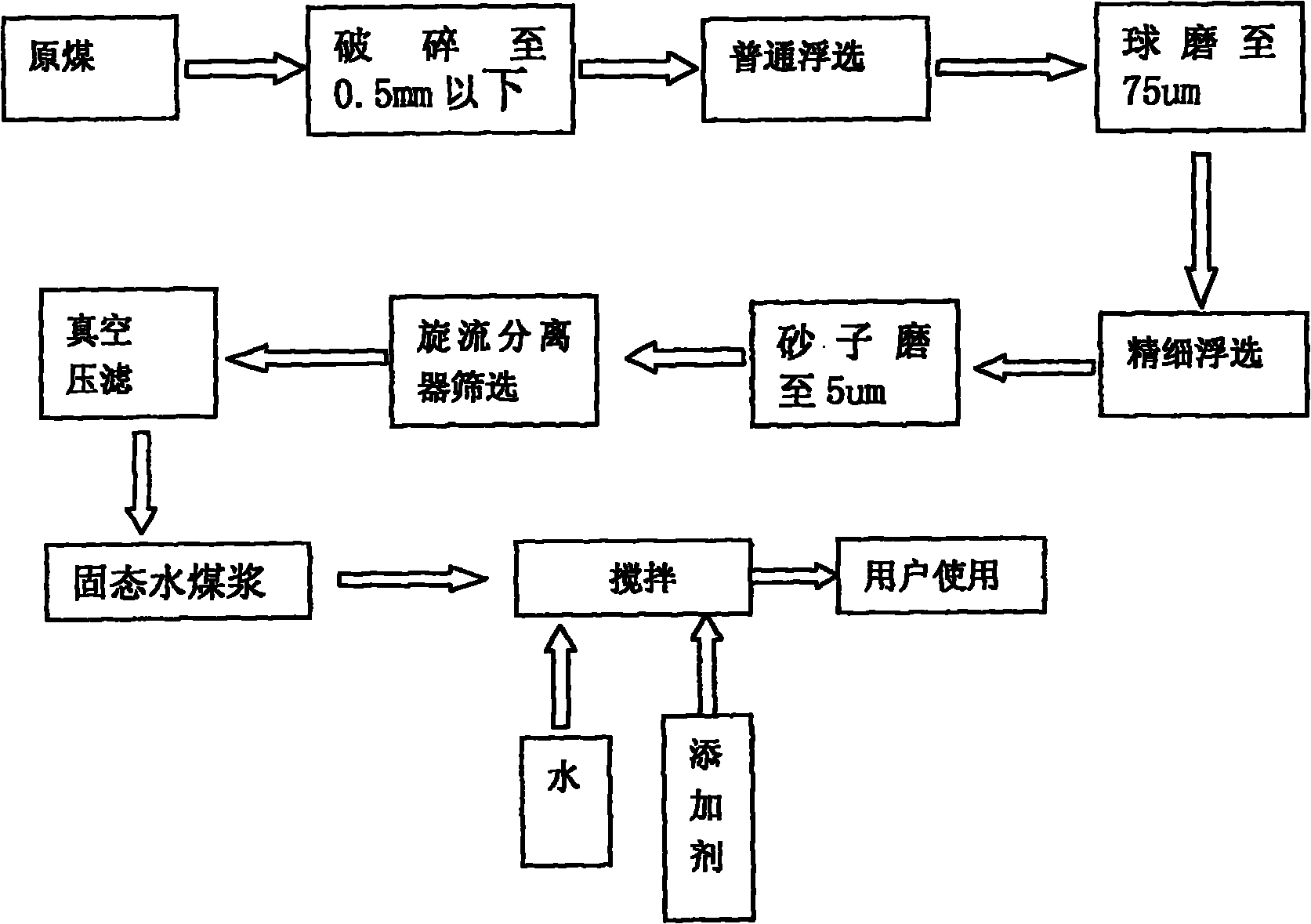

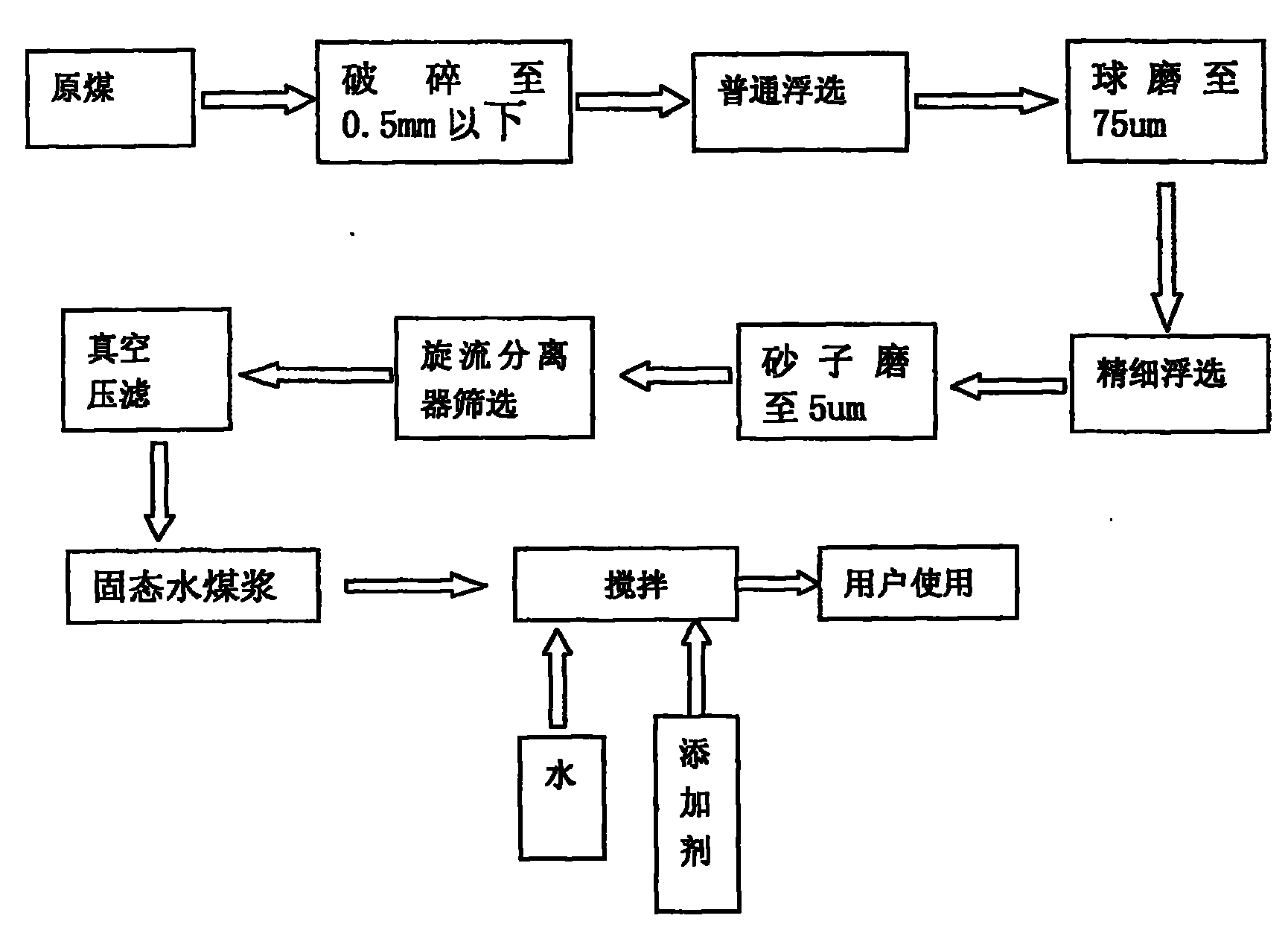

[0017] A kind of slurrying method of novel superfine coal-water slurry, as shown in Figure 1, its manufacture step comprises as follows:

[0018] a. Crushing the raw coal to less than 0.5mm can be carried out with a raw coal crusher. The purpose of crushing to less than 0.5mm is to ensure the effect of ordinary flotation in the next step;

[0019] b. Carry out ordinary flotation treatment on the crushed raw coal powder, and sort out qualified coal particles with ash content less than 10% and sulfur content less than 1%. Ordinary flotation can be carried out in raw coal flotation machines. In order to improve flotation effect, when appropriate, an appropriate amount of flotation agent can be added to it;

[0020] c. Add water to the qualified coal particles from flotation for wet grinding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com