Backlight module, LCD device and method for improving brightness of backlight source

A technology for the brightness of liquid crystal display devices and backlight sources, which is applied in the fields of optics, nonlinear optics, instruments, etc., can solve the problems of poor uniformity of surface light sources and light leakage, and achieve the effect of increasing brightness and improving display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

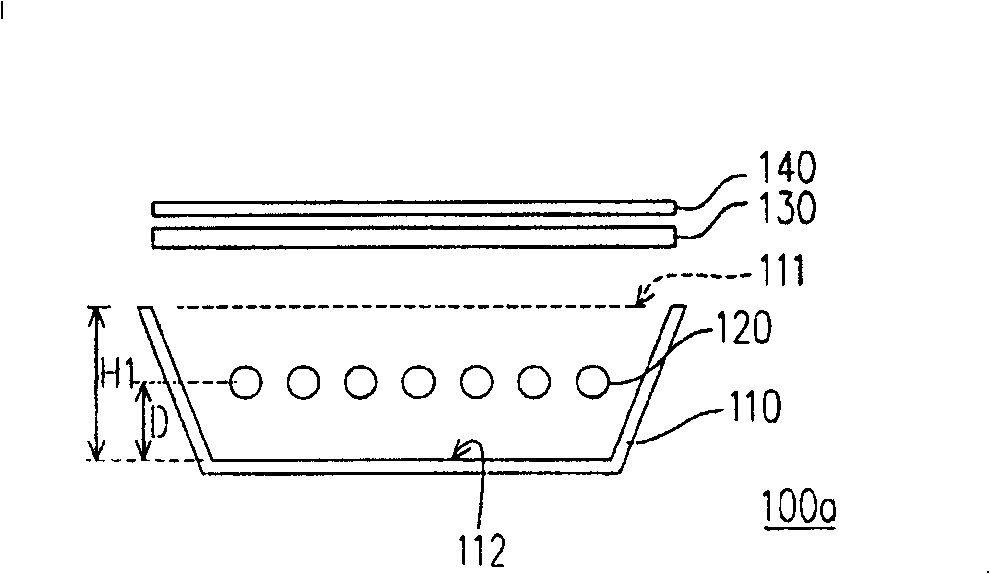

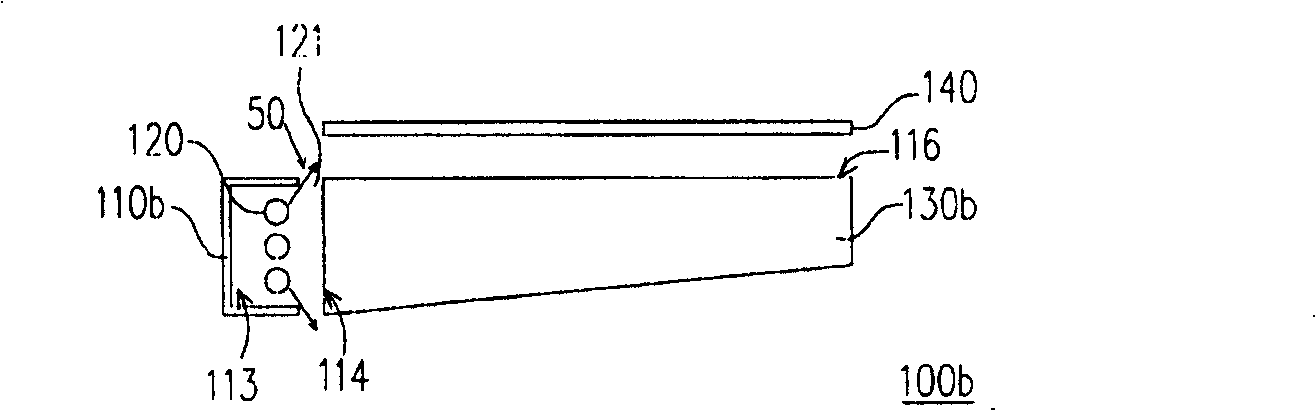

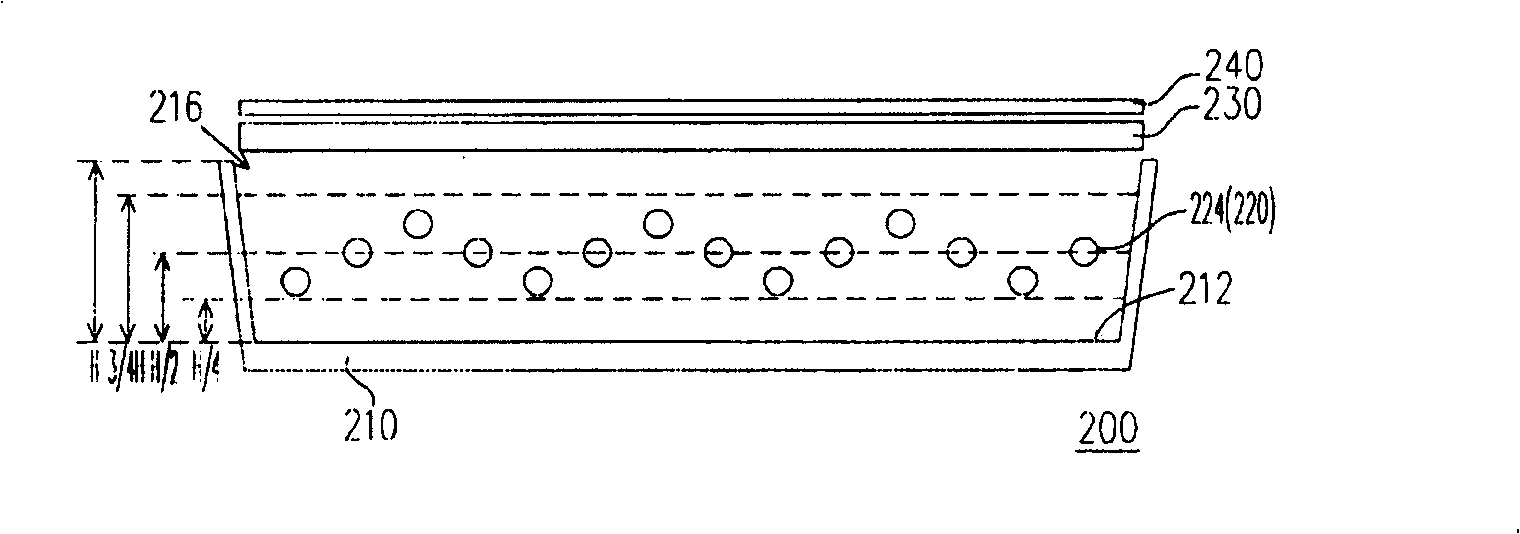

[0079] figure 2 It is a schematic cross-sectional view of a backlight module according to the first embodiment of the present invention, image 3 yes figure 2 A schematic diagram of the connection between a light source and the inverter, and Figure 4 yes figure 2 Schematic diagram of the first light source and the bottom of the light box. Please refer to Figure 2 to Figure 4 , the backlight module 200 of this embodiment is a direct type backlight module, which includes a light box 210 , a plurality of light sources 220 and a diffuser plate 230 . Wherein, the light box 210 has a bottom 212 and a light exit section 216 opposite to each other, and the distance between the bottom 212 of the light box 210 and the light exit section 216 is H. In addition, the light source 220 is disposed in the light box 210 , and the diffusion plate 230 is disposed above the light emitting section 216 of the light box 210 . Each light source 220 has a first end 224 and a second end 226 ....

no. 2 example

[0086] Figure 7 is a schematic cross-sectional view of a backlight module according to the second embodiment of the present invention, and Figure 8 yes Figure 7 A schematic diagram of the connection between a light source and an inverter. Please refer to Figure 7 and Figure 8 , the backlight module 300 of this embodiment is a side-illuminated backlight module, which includes a lampshade 310 , a plurality of light sources 320 and a light guide plate 330 . Wherein, the lampshade 310 has a bottom 312 and a light emitting section 316 opposite to each other, and the distance between the bottom 312 of the lampshade 310 and the light emitting section 316 is H. The light guide plate 330 is arranged beside the light emitting section 316 of the lampshade 310 , and the light source 320 is arranged inside the lampshade 310 . In addition, each light source 320 has a first end 324 and a second end 326 . In order to enhance the brightness of the backlight source provided by the ba...

no. 3 example

[0093] Figure 9 It is a schematic diagram of a liquid crystal display device according to the third embodiment of the present invention. Please refer to Figure 9 , the liquid crystal display device 400 of this embodiment includes a backlight module 484 and a liquid crystal display panel 490 . The backlight module 484 is disposed on one side of the liquid crystal display panel 490 to provide the light source required by the liquid crystal display panel 490 . Wherein, the liquid crystal display panel 490 includes an upper substrate 492 , a lower substrate 494 and a liquid crystal layer 496 arranged between the upper substrate 492 and the lower substrate 494 . The upper substrate 492 can be a color filter substrate, and the lower substrate 494 can be a TFT array substrate. In addition, the backlight module 484 is the direct type backlight module described in the first embodiment or the side light type backlight module described in the second embodiment.

[0094] Since the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com