Packaging conductive structure and its forming method

A conductive structure and conductive layer technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as open circuit, difficult deposition, semiconductor chip failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

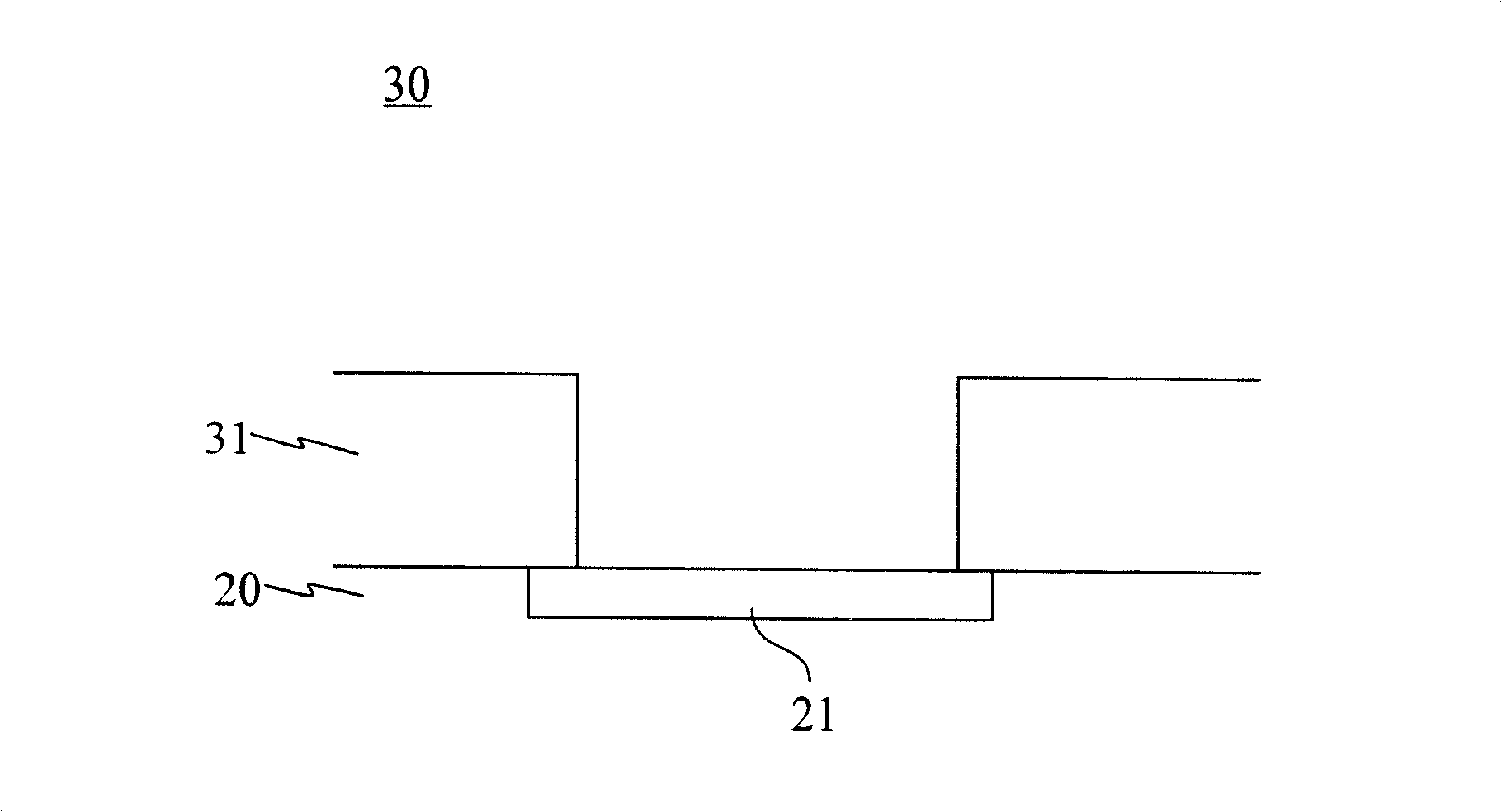

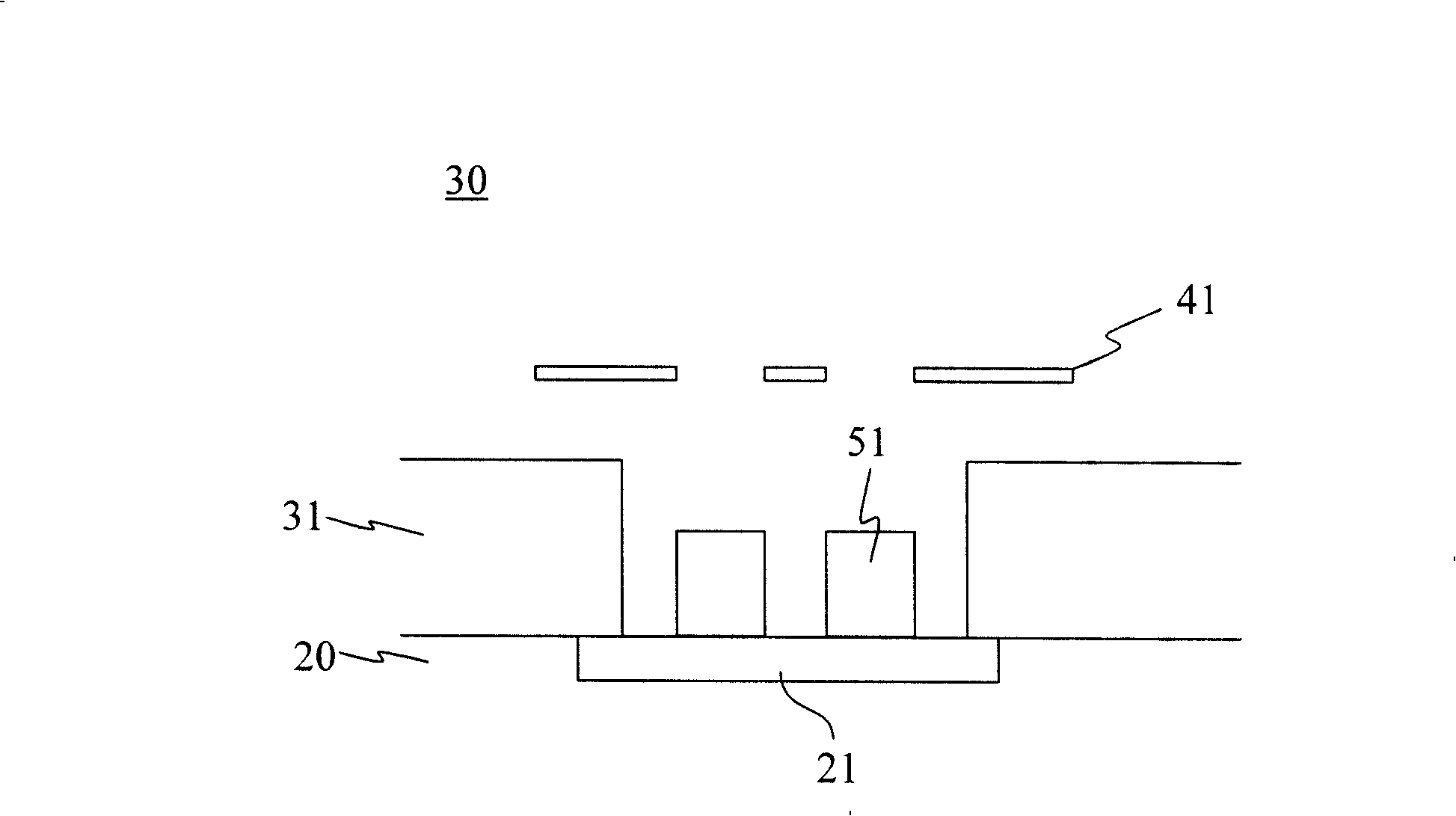

[0023] Please see first Figure 2A , the packaging conductive structure 30 of the present invention is applied to the semiconductor substrate 20, and the semiconductor substrate 20 usually has a metal layer 21, that is, a pad, as a contact for electrical connection. Generally speaking, the metal layer 21 is usually made of aluminum, and after being combined with the packaging conductive structure 30 of the present invention, subsequent electrical connection with other external components can be performed.

[0024] Firstly, a dielectric layer 31 is formed on the semiconductor substrate 20, which partially covers the metal layer 21 and defines an accommodating space so that the metal layer 21 can be partially exposed. More specifically, a large area of dielectric material can be formed first, and then a photoresist layer (not shown) is partially formed on it, and then an etching process is performed to remove the part of the dielectric layer not covered by the photoresist laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com