Light aluminum alloy cable chain tightener

An aluminum alloy and wire tensioner technology, which is applied to portable lifting devices, hoisting devices, etc., can solve problems such as being unfavorable for maintenance, adjusting the working position of the tail ring restricting device, and having a large impact, so as to avoid the phenomenon of chain wrapping and chain overturning. , The effect of reducing the number of hoisting chains and facilitating climbing at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

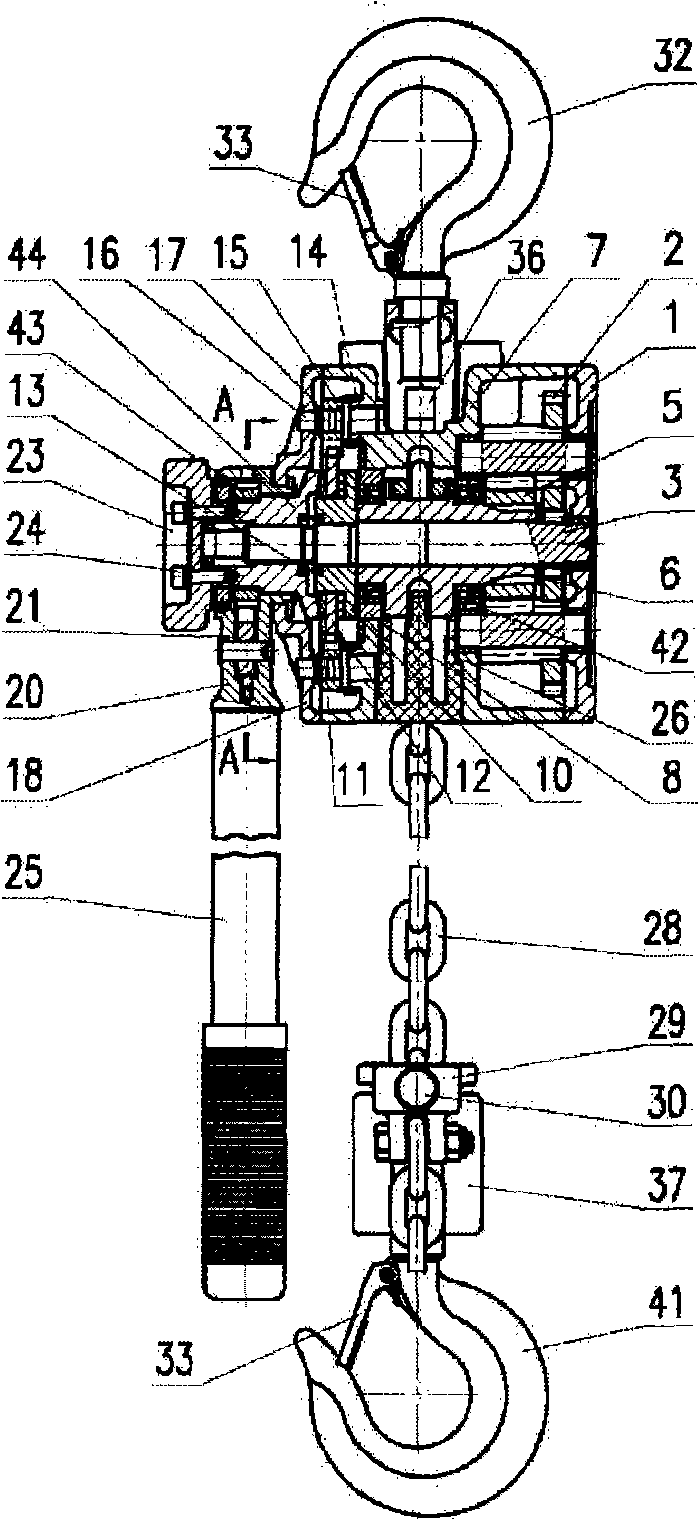

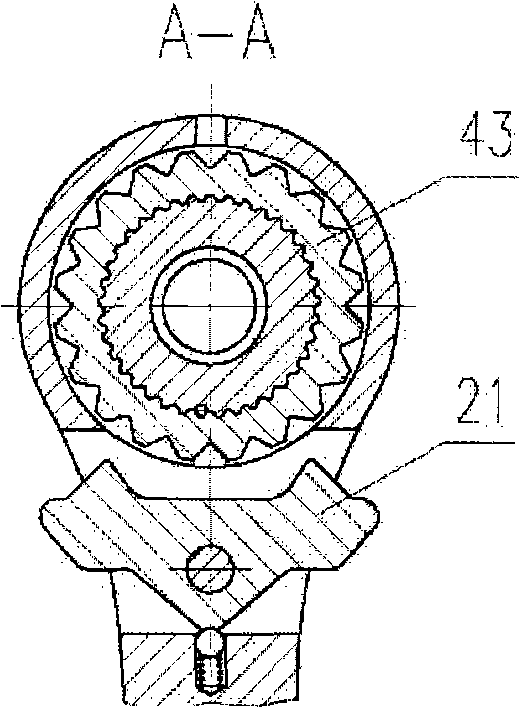

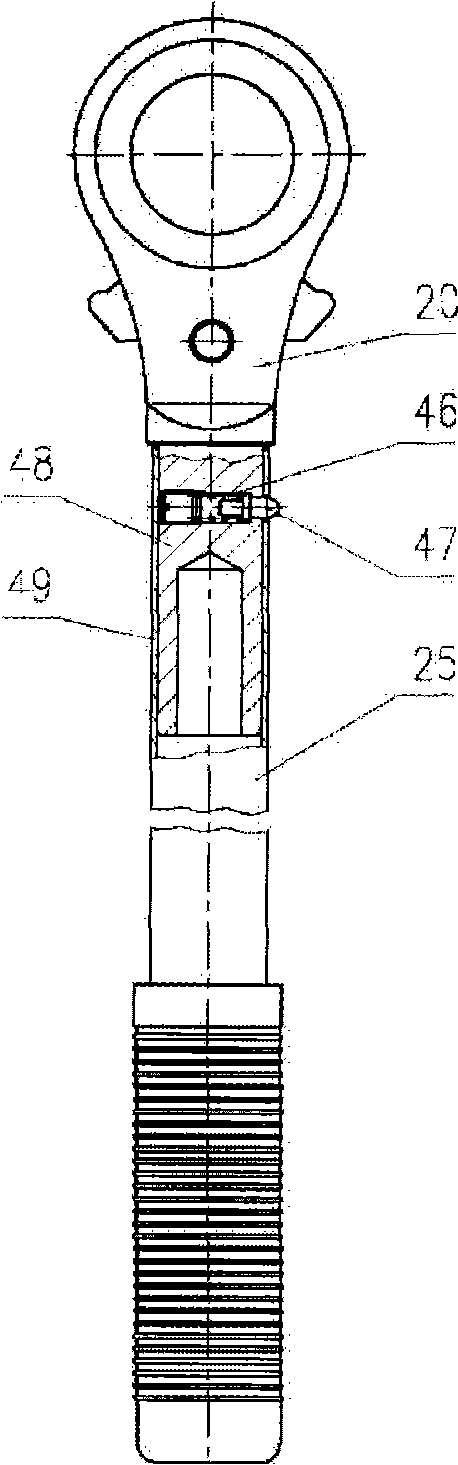

[0014] Embodiment 1: with reference to attached Figure 1-7 . Lightweight aluminum alloy ring chain tensioner, which includes a body, a transmission mechanism, a drag chain mechanism, an operating mechanism, a hanging connection device, a tail ring limiting device and a chain guide. Described body is made of exterior wall panel 1, frame 7, ratchet cover 18 and guide chain block 26, and exterior wall panel 1 and ratchet cover 18 refer to attached figure 1 and 7 Process and manufacture by prior art and be respectively positioned at frame 7 both sides, frame 7 refers to attached figure 1 and 7 According to prior art die-casting molding or pouring molding, guide chain block 26 with reference to attached figure 1 and 7 Injection molding according to the prior art (the chain guide block 26 of the chain guide part is made of engineering plastics or reinforced nylon) and is positioned at the bottom of the frame 7, and the top of the frame 7 has a concave groove (designed in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com