Secondary hole sealing method capable of improving coal bed drilling firedamp sucking concentration

A technology for gas drainage and secondary hole sealing, which is used in gas drainage, earthwork drilling, safety devices, etc., can solve the problem of shortening the effective drainage period of drainage holes, affecting the safety of the gas drainage system and the concentration of gas drainage. It can reduce the problems such as decline, and achieve the effect of extending the effective drainage period, improving the gas drainage effect, and increasing the gas drainage concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

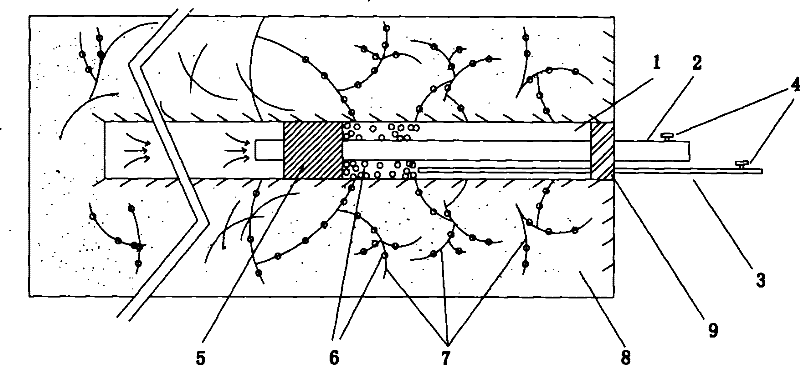

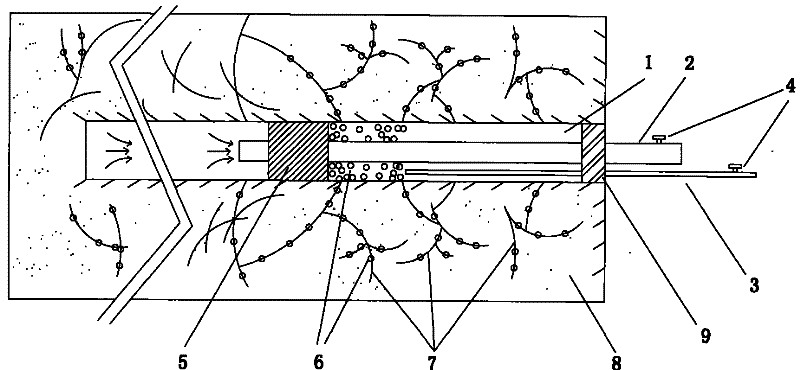

[0013] An example of the present invention will be further described below in conjunction with accompanying drawing:

[0014] As shown in the accompanying drawings, the first hole sealing is to drill holes into the coal seam on the coal body 8 of the working face until the design depth requirement is reached, then insert the drain pipe 2, apply the polyurethane 5 evenly on the sack, and quickly put the The sack is wrapped around the hole sealer, and then sent into the coal seam borehole 1 about 10m away. At this time, the polyurethane 5 undergoes a chemical reaction and expands to seal the borehole. At this time, open the valve 4 on the drainage pipe 2. Implement gas drainage. After a certain period of gas drainage, due to the deformation and displacement of the coal seam, the pores (cracks) in the coal seam around the borehole expand and develop, and the outside air easily enters the bottom of the hole through the crack channel, so that the gas drainage concentration drops si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com