Back board assembly for backlight module

A backlight module and assembly technology, which is applied in optics, nonlinear optics, and damage prevention measures for lighting devices, and can solve problems such as failure to operate normally, affecting performance, and unfavorable thinning of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

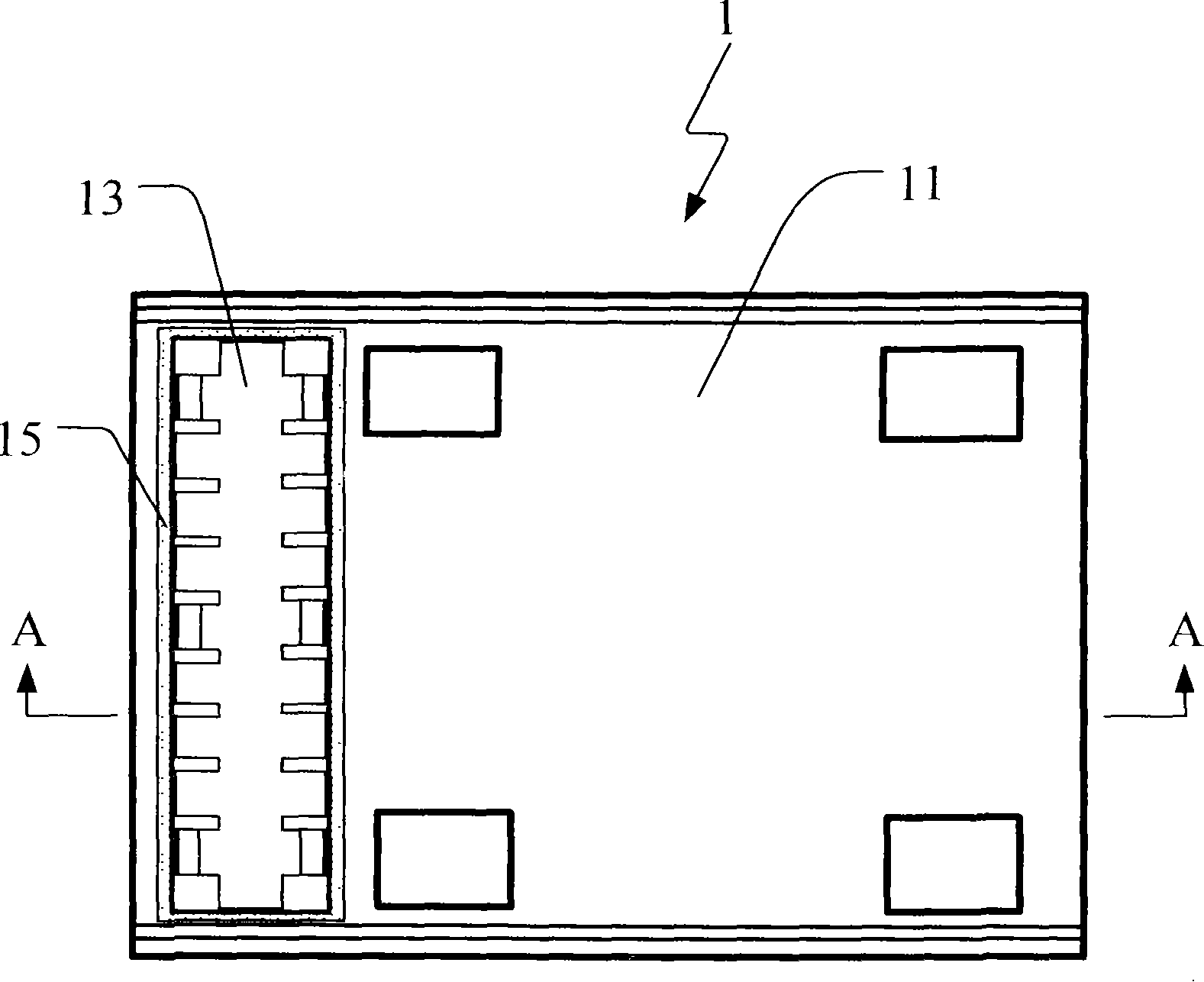

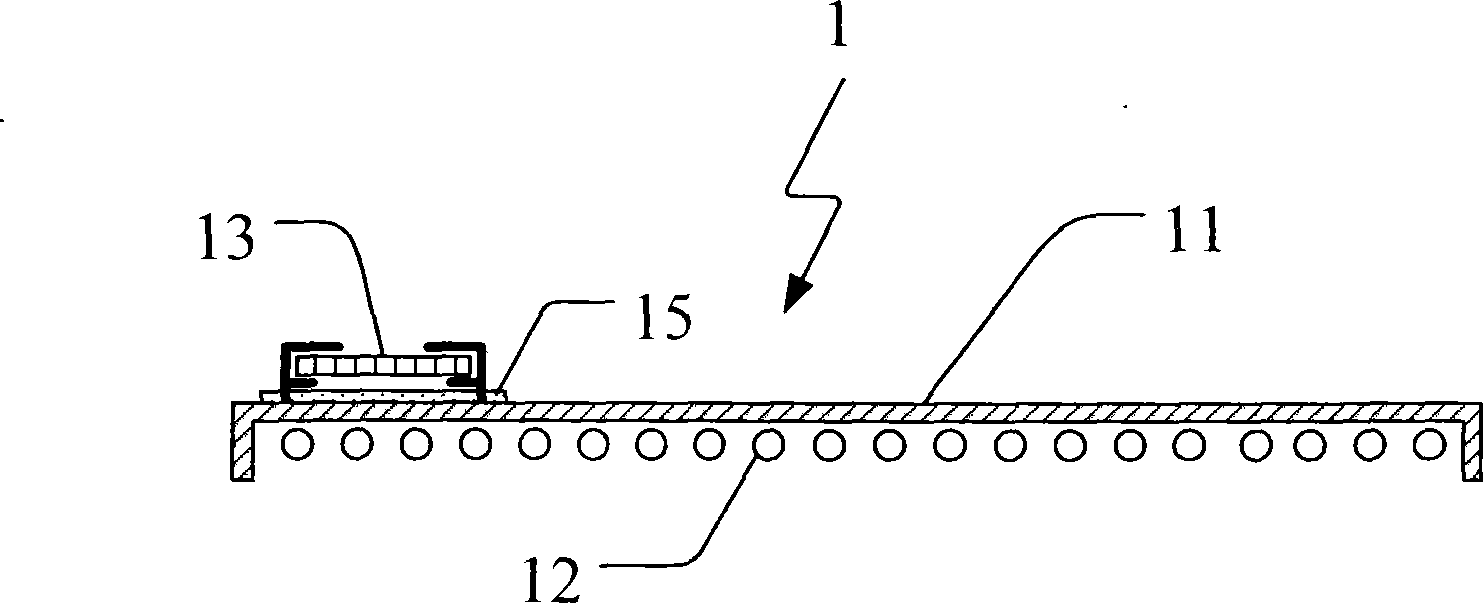

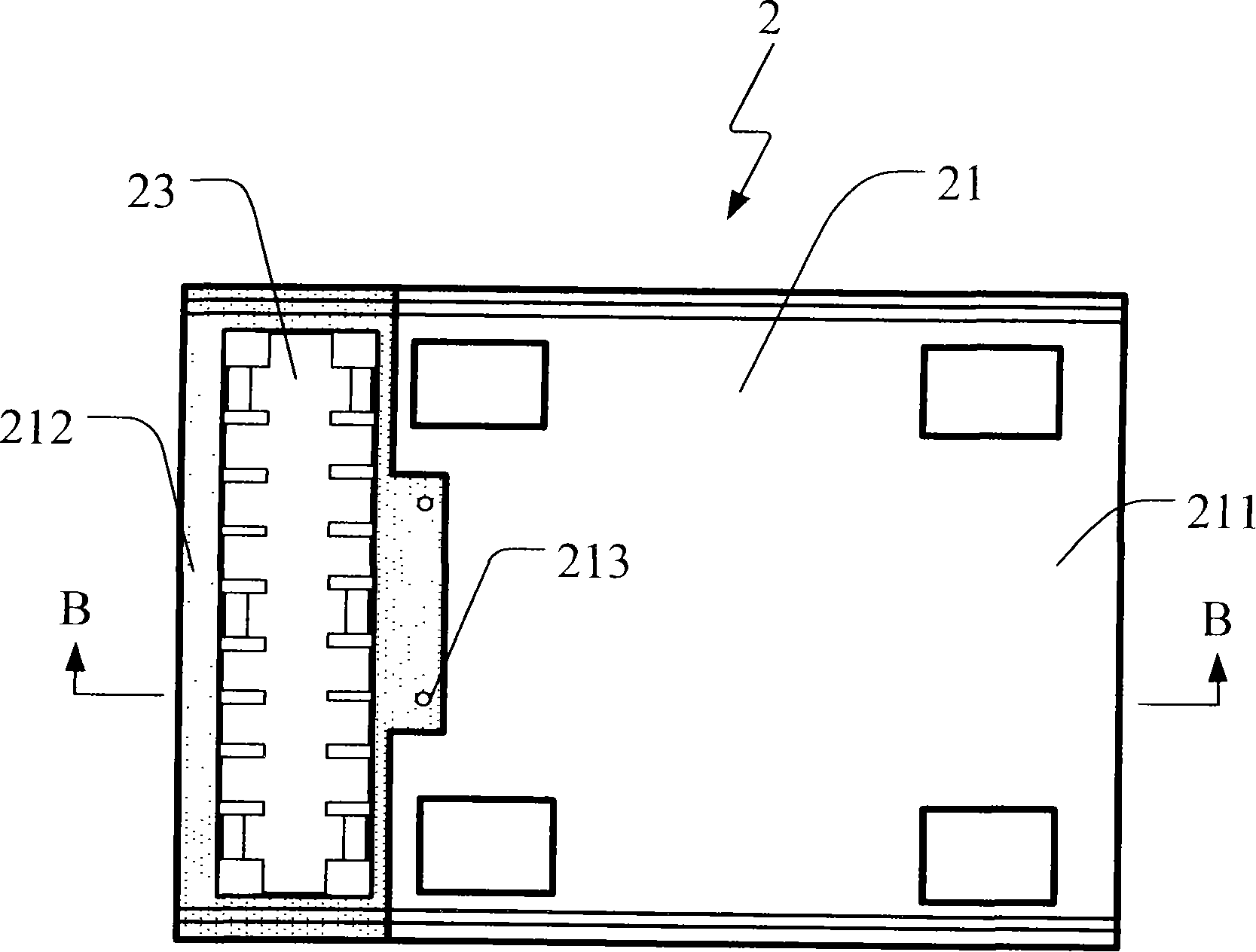

[0022] Please refer to Figure 2A and Figure 2B ,in Figure 2B for along Figure 2A Schematic diagram of the cross-section of the B-B section line. The backlight module 2 of the present invention at least includes a backplane assembly 21 , a light source device 22 and an inverter 23 , wherein the light source device 22 and the inverter 23 are substantially isolated by the backplane assembly 21 . More specifically, in order to improve the shortcomings of existing backlight modules that conduct high heat generated by the light source device to the igniter through the back plate, thereby generating local high temperature and affecting the operation of the igniter, the back plate assembly 21 of the present invention uses different The regions have materials with different thermal conductivity coefficients, so as to isolate the high heat generated by the light source device 22 from being conducted to the lighter 23 and still maintain the heat dissipation of the light source dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com