Gas-filled type dielectric elastomer hemi-spherical driver

A dielectric elastomer, hemispherical technology, applied in the direction of generator/motor, electrostatic generator/motor, electrical components, etc., can solve the problems of complex mechanical structure, long response time, poor bionic performance, etc., and achieve simple mechanical structure , short response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

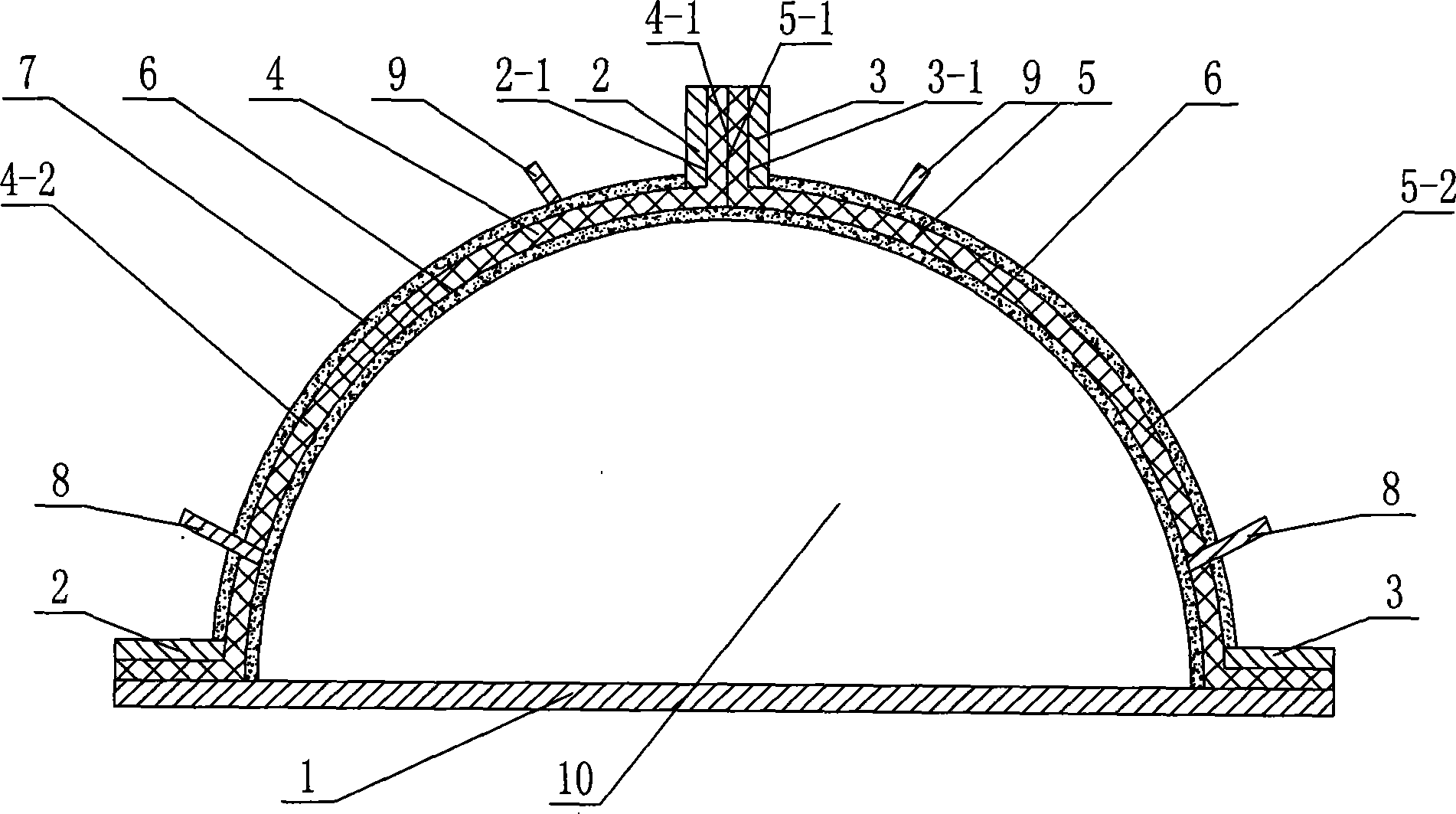

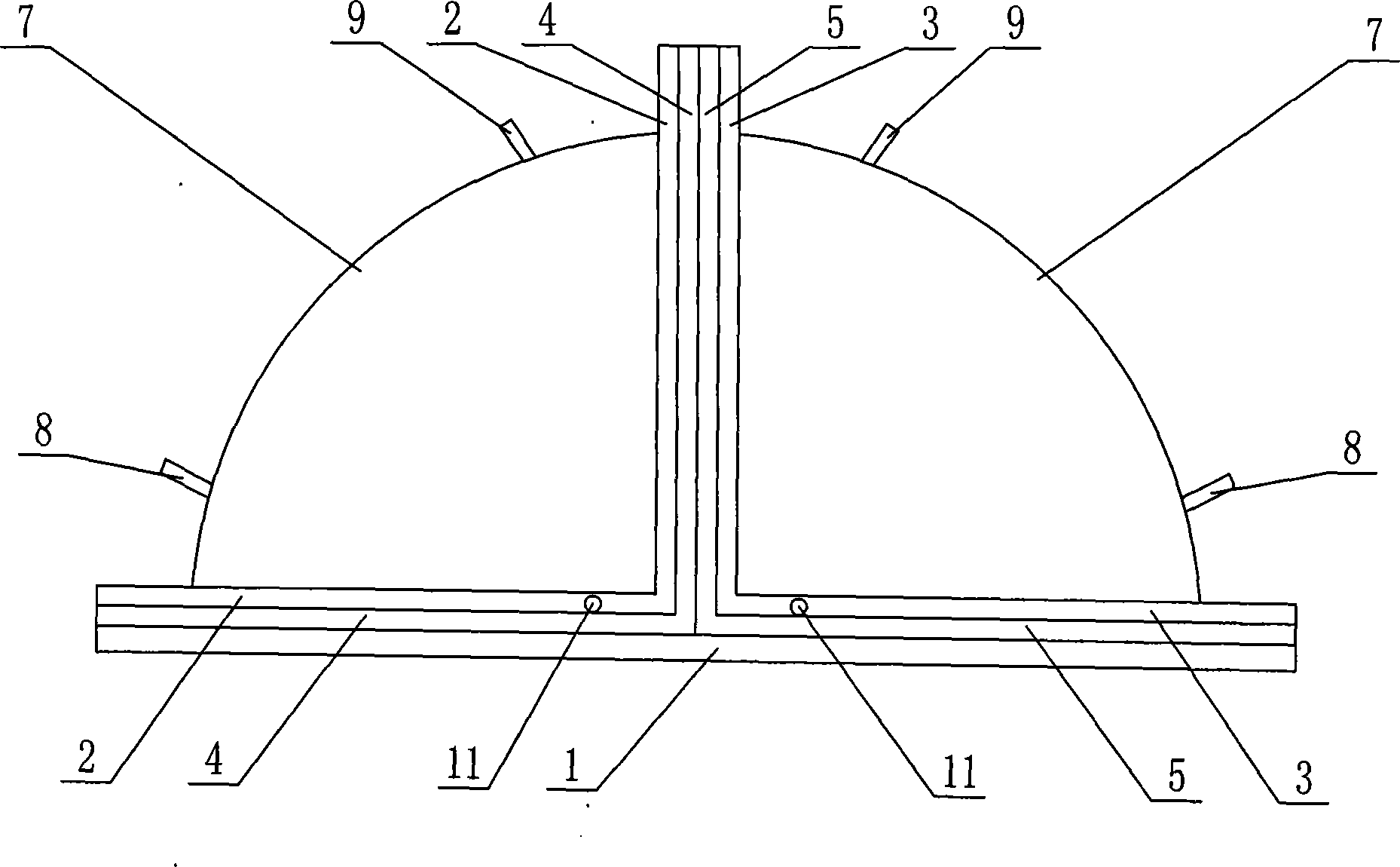

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 2 This embodiment is described. This embodiment consists of a substrate 1, a first film 2, a second film 3, a first pre-stretched dielectric elastomer film 4, a second pre-stretched dielectric elastomer film 5, and a first electrode 6. , the second electrode 7, the first aluminum foil 8 and the second aluminum foil 9, the inner surface 2-1 of the first film 2 is covered with a first pre-stretched dielectric elastomer film 4, and the second film The inner surface 3-1 of 3 is covered with a second pre-stretched dielectric elastomer film 5, the bottom end surface of the first pre-stretched dielectric elastomer film 4 and the second pre-stretched dielectric elastomer film The bottom end surface of 5 is attached to the upper end surface of substrate 1, and the inner facade 4-1 of the upper end of the first pre-stretched dielectric elastomer film 4 and the inner vertical surface 4-1 of the upper end of the second pr...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described. The thicknesses of the first pre-stretched dielectric elastomer film 4 and the second pre-stretched dielectric elastomer film 5 of the present embodiment are both 0.1 mm to 1 mm. With such a setting, the flexibility is better, the required driving voltage is lower, and the bionic performance is better. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The thicknesses of the first electrode 6 and the second electrode 7 in the present embodiment are both 0.0005 mm to 0.005 mm. With such a setting, the flexibility is better, the deformation is larger, the driving force is larger, and the bionic performance is better. Other compositions and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com