Preparation of maleated rosin polyethenoxy ether diester carboxyl acid natrium surfactant

The technology of rosin polyoxyethylene ether and rosin octylphenol polyoxyethylene ether is applied in the field of preparation of polyoxyethylene ether diester sodium carboxylate surfactant, and can solve the problems of poor water solubility, corrosion in production, low emulsifying ability, etc. problem, to achieve the effect of good water-soluble stability, strong degreasing power and moderate foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

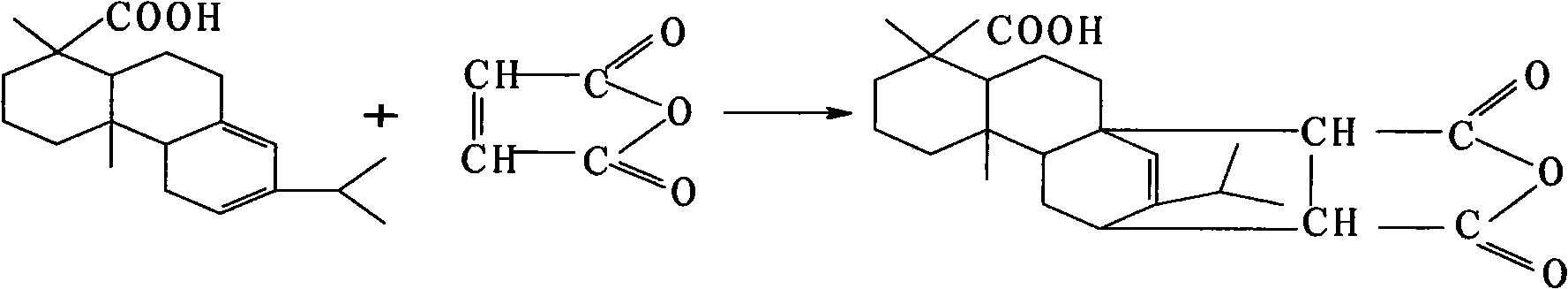

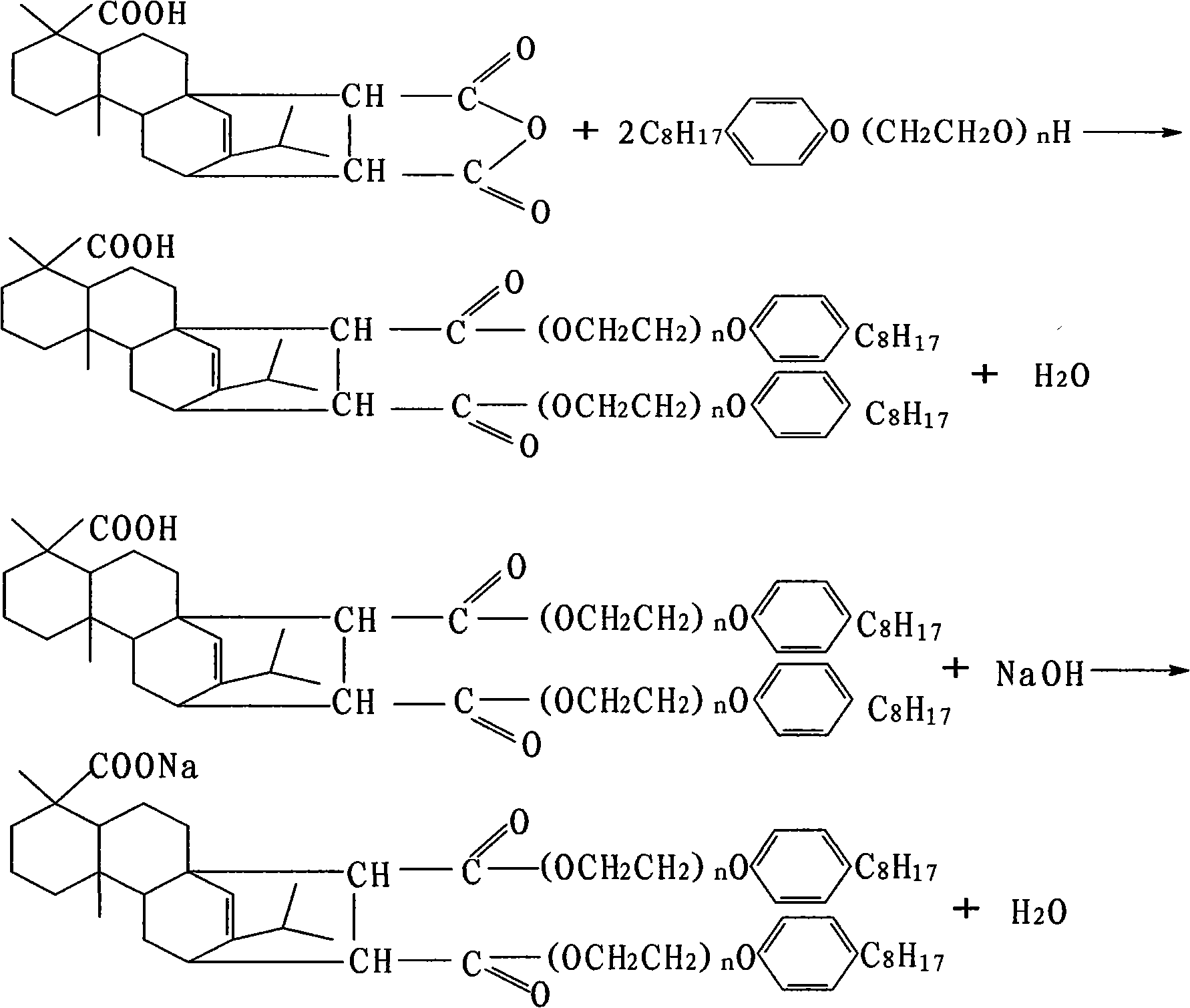

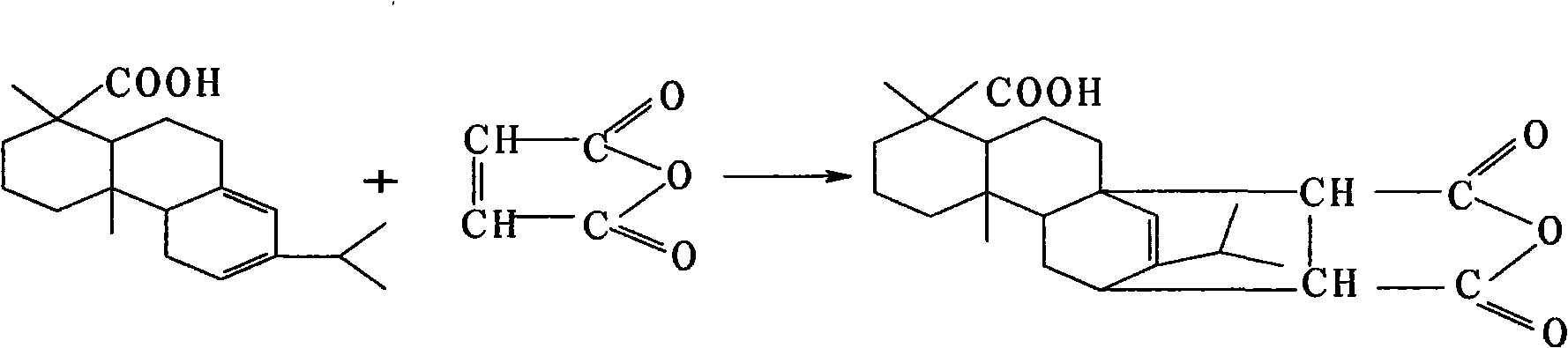

[0020] (1) Synthesis of Maleic Rosin

[0021] Accurately weigh 681g of super-grade rosin and crush it. First, put 1 / 4 of the total amount of crushed rosin into a container equipped with electric stirring, condenser, thermometer, and N 2 Into a 1000ml four-necked reaction bottle heated by a protective device and an electric heating mantle, heat and stir intermittently. After the material is melted, continue to stir, and add the remaining rosin in batches. Block, prolong the time of compounding in due time, 120~130℃ for compounding, in order to prevent the high temperature from oxidizing the rosin and deepening the color of the resin, the kettle should be filled with N 2 Protect. After the rosin is completely melted, slowly add 102g of maleic anhydride in four times, the addition reaction is an exothermic reaction, and the temperature will rise automatically. Do not add maleic anhydride too fast, otherwise, it will cause overflowing the pot and spray the maleic anhydride. Afte...

Embodiment 2

[0025] (1) Synthesis of Maleic Rosin

[0026] Accurately weigh 665g of super-grade rosin and crush it. First, put 1 / 4 of the total amount of crushed rosin into a container equipped with electric stirring, condenser, thermometer, and N 2 Into a 1000ml four-necked reaction bottle heated by a protective device and an electric heating mantle, heat and stir intermittently. After the material is melted, continue to stir, and add the remaining rosin in batches. Block, prolong the time of compounding in due time, 120~130℃ for compounding, in order to prevent the high temperature from oxidizing the rosin and deepening the color of the resin, the kettle should be filled with N 2 Protect. After the rosin is completely melted, slowly add 118g of maleic anhydride in four times. The addition reaction is an exothermic reaction, and the temperature will automatically rise. Do not add maleic anhydride too fast, otherwise, it will cause overflowing the pot and spraying the maleic anhydride. A...

Embodiment 3

[0030] (1) Synthesis of Maleic Rosin

[0031] Accurately weigh 697g of super-grade rosin and crush it. First, put 1 / 4 of the total amount of crushed rosin into a container equipped with electric stirring, condenser, thermometer, and N 2 Into a 1000ml four-necked reaction bottle heated by a protective device and an electric heating mantle, heat and stir intermittently. After the material is melted, continue to stir, and add the remaining rosin in batches. Block, prolong the time of compounding in due time, 120~130℃ for compounding, in order to prevent the high temperature from oxidizing the rosin and deepening the color of the resin, the kettle should be filled with N 2 Protect. After the rosin is completely melted, slowly add 86g of maleic anhydride in four times. The addition reaction is an exothermic reaction, and the temperature will rise automatically. Do not add maleic anhydride too fast, otherwise, it will cause overflowing the pot and spray the maleic anhydride. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com