Renewable sources granular fuel making method and ring mould thereof

A pellet fuel and renewable energy technology, which is applied in the direction of manufacturing tools, material molding presses, presses, etc., can solve the problems of low molding rate and production efficiency of pellet fuel, insufficient compression ratio of pellet machine, high manufacturing cost, etc., and achieve effective Conducive to environmental protection, scientific and reasonable design and matching, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

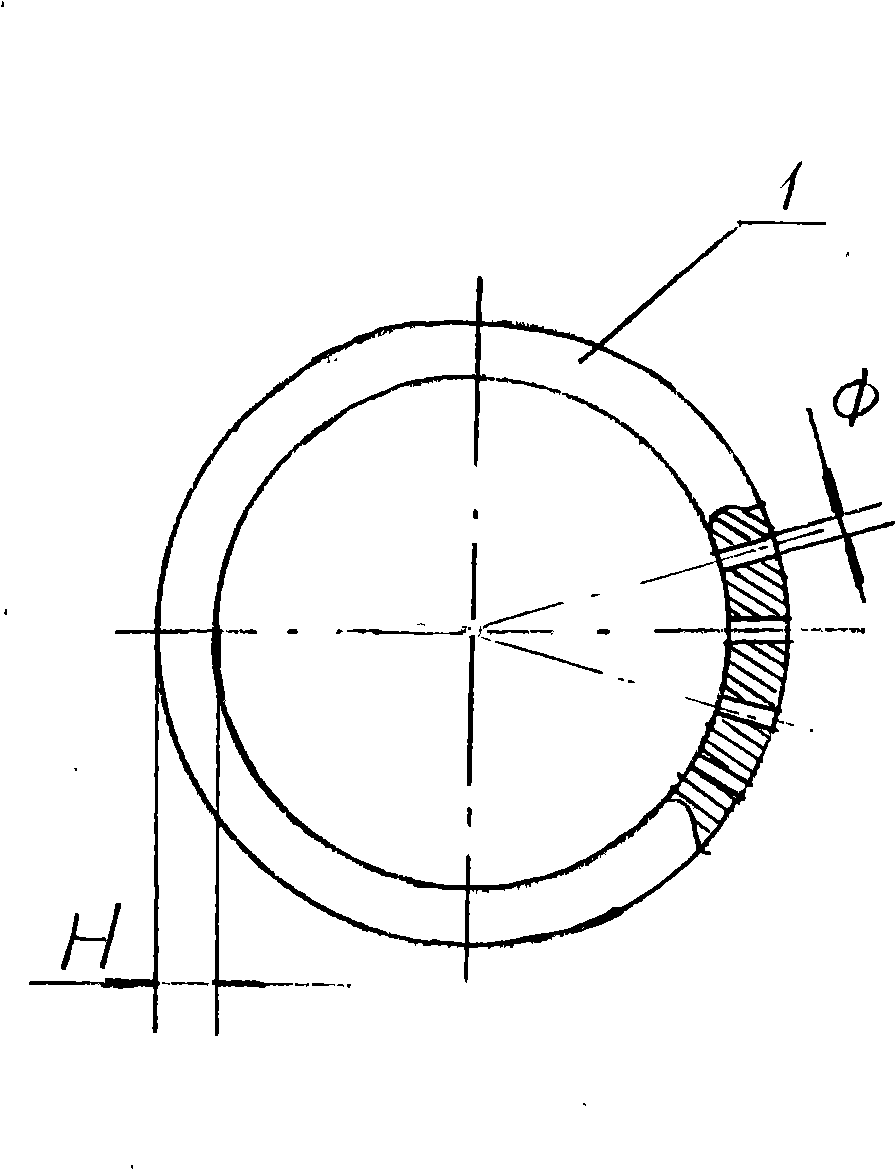

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The manufacturing method of the renewable energy granular fuel is to directly send uncrushed sunflower husks, rice husks, or corn stalks cut to a length of ≤ 1 cm into a granular fuel forming machine for forming and processing to obtain the renewable energy granular fuel. Renewable energy granular fuel is used to make ring dies, on ring die 1: ①, processing uncrushed rice husks or corn stalk sections less than or equal to 1 cm long: when ring die 1 die hole diameter Φ is 6 mm, the ring die The thickness H of the die 1 is 42 mm; when the diameter of the die hole of the ring die 1 is 7 mm, the thickness H of the ring die 1 is 70 mm; when the diameter of the die hole of the ring die 1 is 8 mm, the thickness H of the ring die 1 is 104 mm; ②, processing un-crushed sunflower shells: when the diameter of ring die 1 die hole Φ is 6 mm, the thickness H of ring di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com