Method for coal-blending coking by using waste plastics

A technology for blending coal for coking and waste plastics, used in coke ovens, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

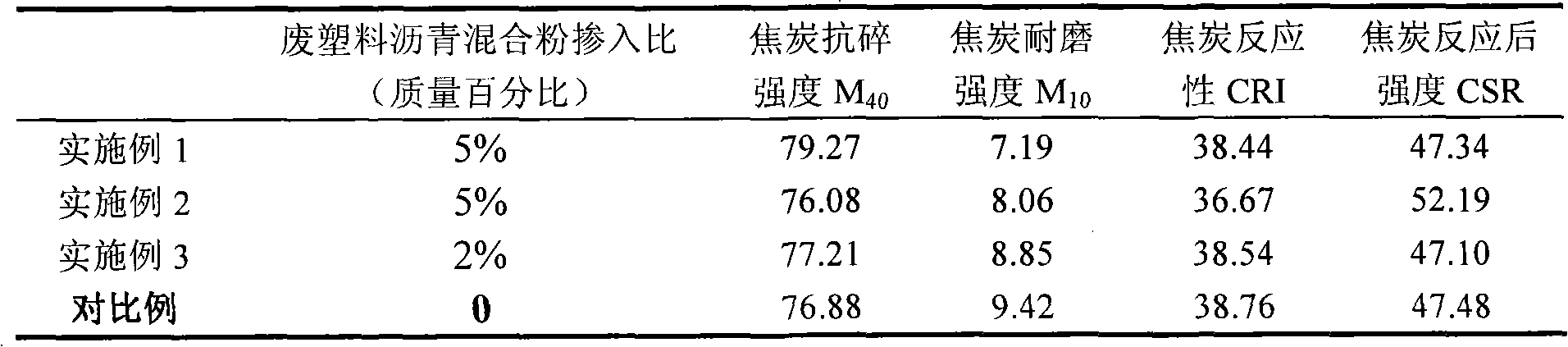

[0019] Embodiment 1: 40Kg test coke oven coking

[0020] (1) Add coal tar medium-temperature asphalt with a temperature of about 380°C from the tar processing workshop of the coking plant into the melting tank, then add waste plastics, and stir at the same time to melt the waste plastics in a liquid state at a temperature of 150-380°C In asphalt, the time is 10-20 minutes; the mass ratio of waste plastics to coal tar asphalt is 1:4;

[0021] (2) After melting, the waste plastic asphalt mixture is cooled to 30°C, and then crushed to a particle size below 3 mm with a pulverizer; the crushed waste plastic asphalt mixture is added to the coal blending chamber of the coking plant in a mass ratio of 5%. It is taken from the blended coal after the pulverizer in the coking plant;

[0022] (3) pulverize and mix the above-mentioned mixed coal blended with the mixture through the pulverizer of the existing coking coal pulverizing process first; then utilize the original transport belt t...

Embodiment 2

[0023] Embodiment 2: As described in Embodiment 1, the difference is that the mass ratio of waste plastics to coal tar pitch is 2:3 in step (1).

Embodiment 3

[0024] Embodiment 3: As described in Embodiment 1, the difference is that in step (2), the waste plastic asphalt mixed powder is added to the blended coal in a mass ratio of 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com