Nitrogen-silicon congruent melting alloy, method for manufacturing same and use

A eutectic and alloying technology, applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth, etc., can solve the problems of fluctuation of silicon nitride formation amount, large weighing error, and small amount of doping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a quartz crucible with a diameter of 356 mm, 1 gram of silicon nitride and 45,000 grams of polysilicon were respectively added. After the melting was completed, the polysilicon was cooled, and the nitrogen concentration in the polysilicon was measured by sampling to be 7E17 atoms / cm3.

Embodiment 2

[0022] In a quartz crucible with a diameter of 254 mm, 24 mg and 10,000 grams of silicon nitride and polysilicon were added respectively. After melting, the polysilicon was cooled, and the nitrogen concentration in the polysilicon was measured by sampling to be 7E16 atoms / cm3.

Embodiment 3

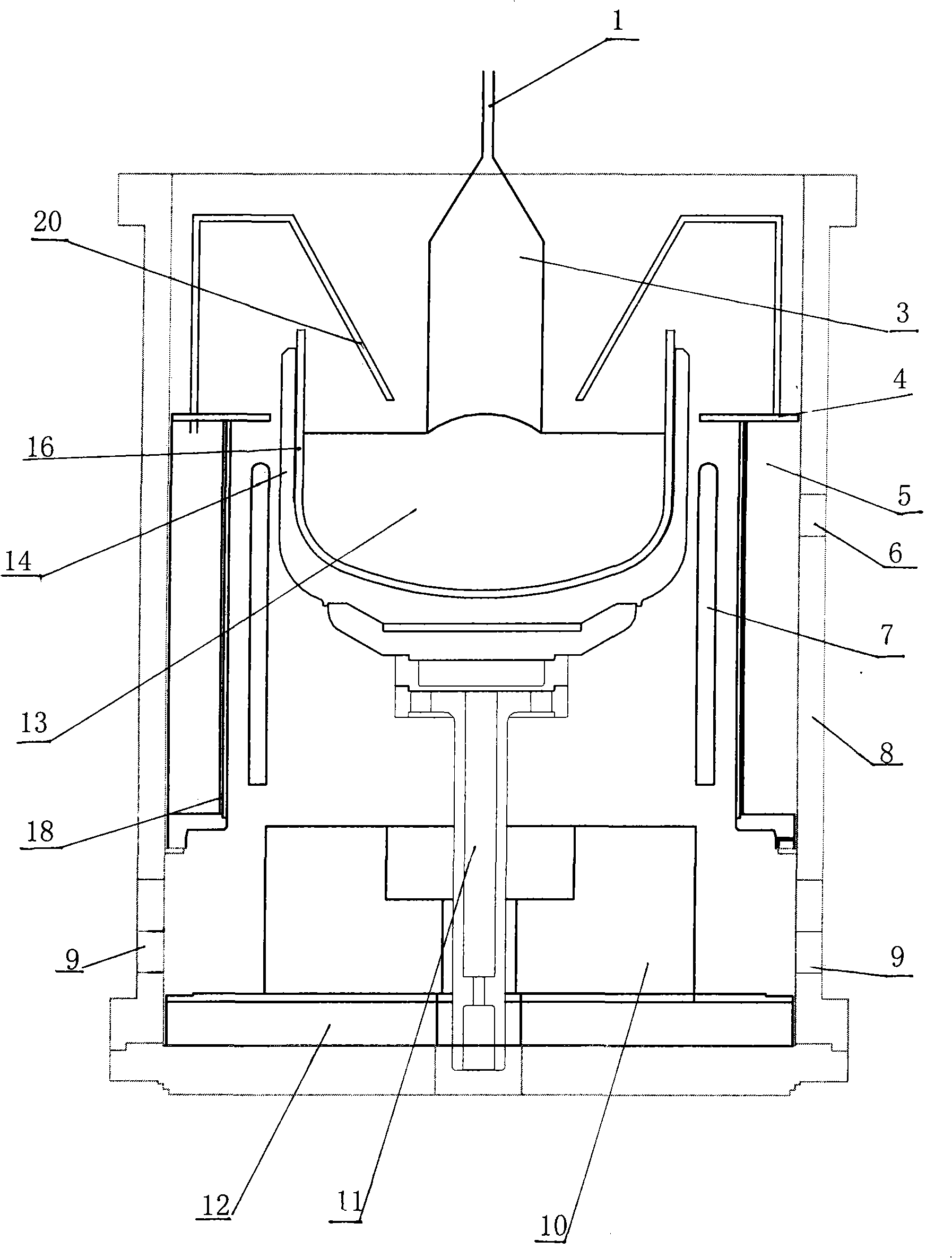

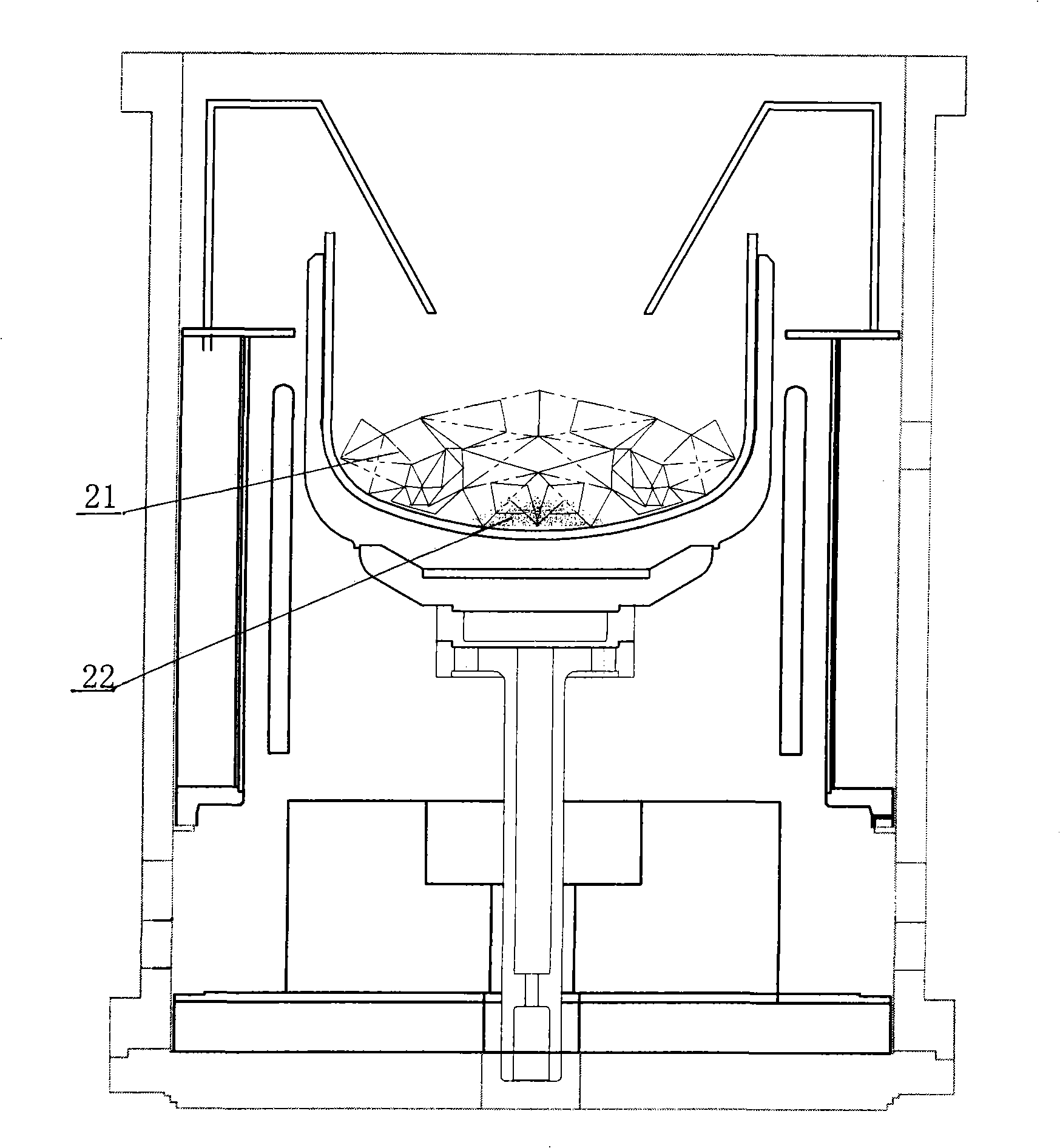

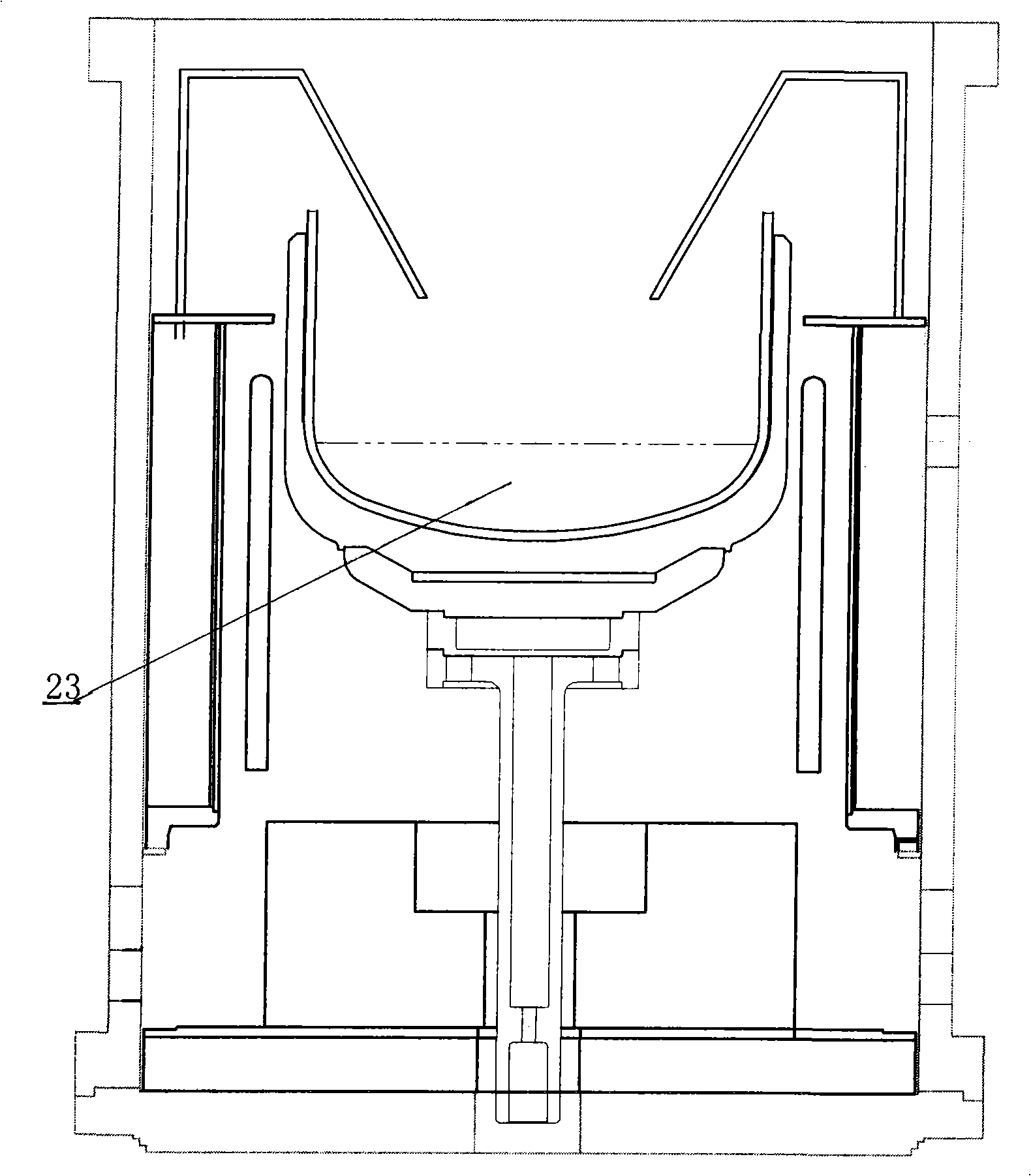

[0024] The specific manufacturing method of silicon nitride eutectic alloy is described as follows: on the thermal field used for crystal pulling, first put the quartz crucible into the graphite crucible, put a certain amount of silicon nitride powder on the bottom of the quartz crucible, and then add For polysilicon, argon gas is introduced, and pumping is used at the same time to keep the pressure inside the furnace at 4-50 torr, and the power is increased to melt the polysilicon until it is completely melted, and the heating power is maintained until the silicon nitride powder is completely melted. Then reduce the heating power to 0 in 1-10 times, and after cooling for several hours, take out the polysilicon at the bottom of the crucible together with the adhered quartz. The quartz is then removed with hydrofluoric acid. Take the polycrystalline block to measure the nitrogen content inside. This polysilicon is then broken and cleaned. This is the nitrogen-containing polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com