Fabrication method of superjunction device

A manufacturing method and super junction technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the increase in the concentration of the P region, the smaller the N-type column, and the reduction of source-drain conductance. The effect of on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

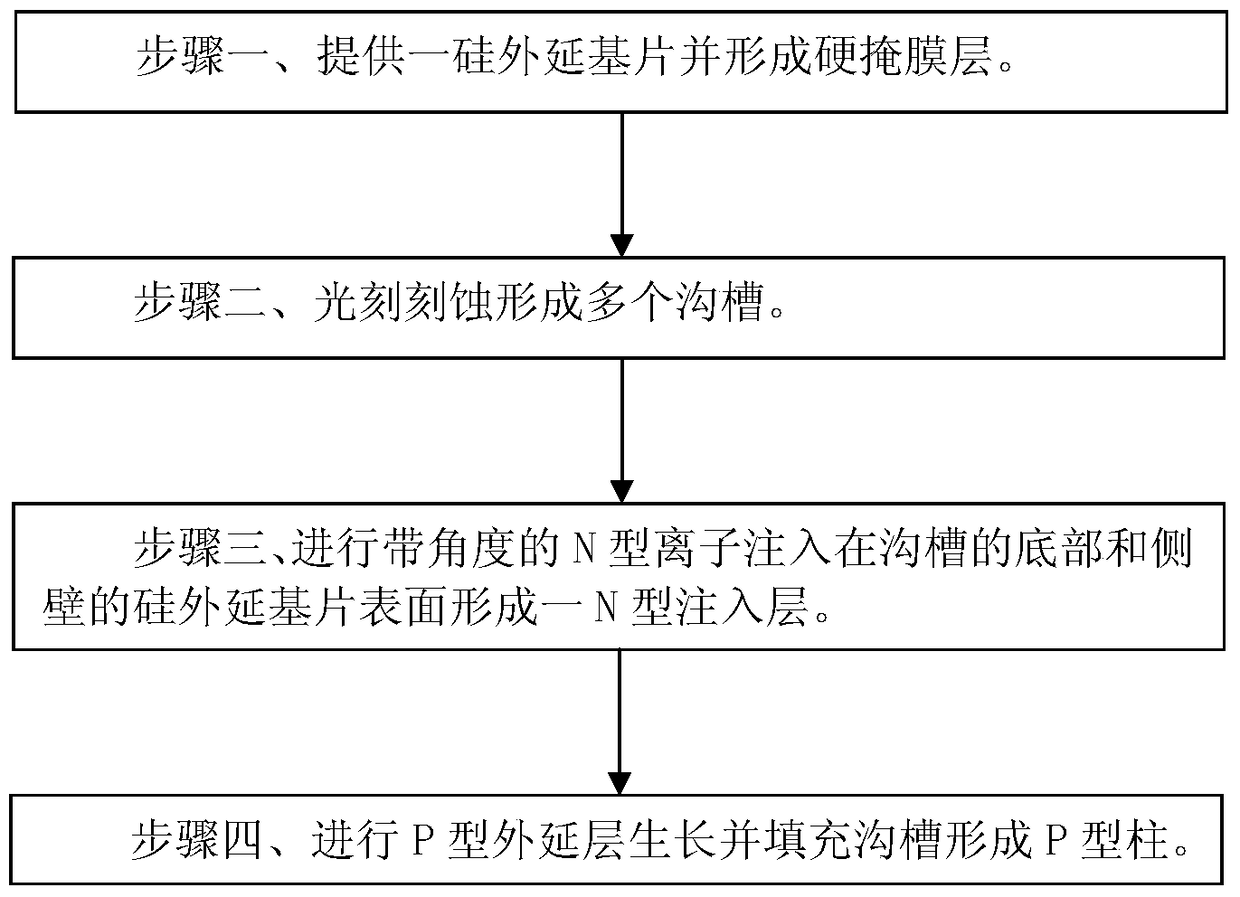

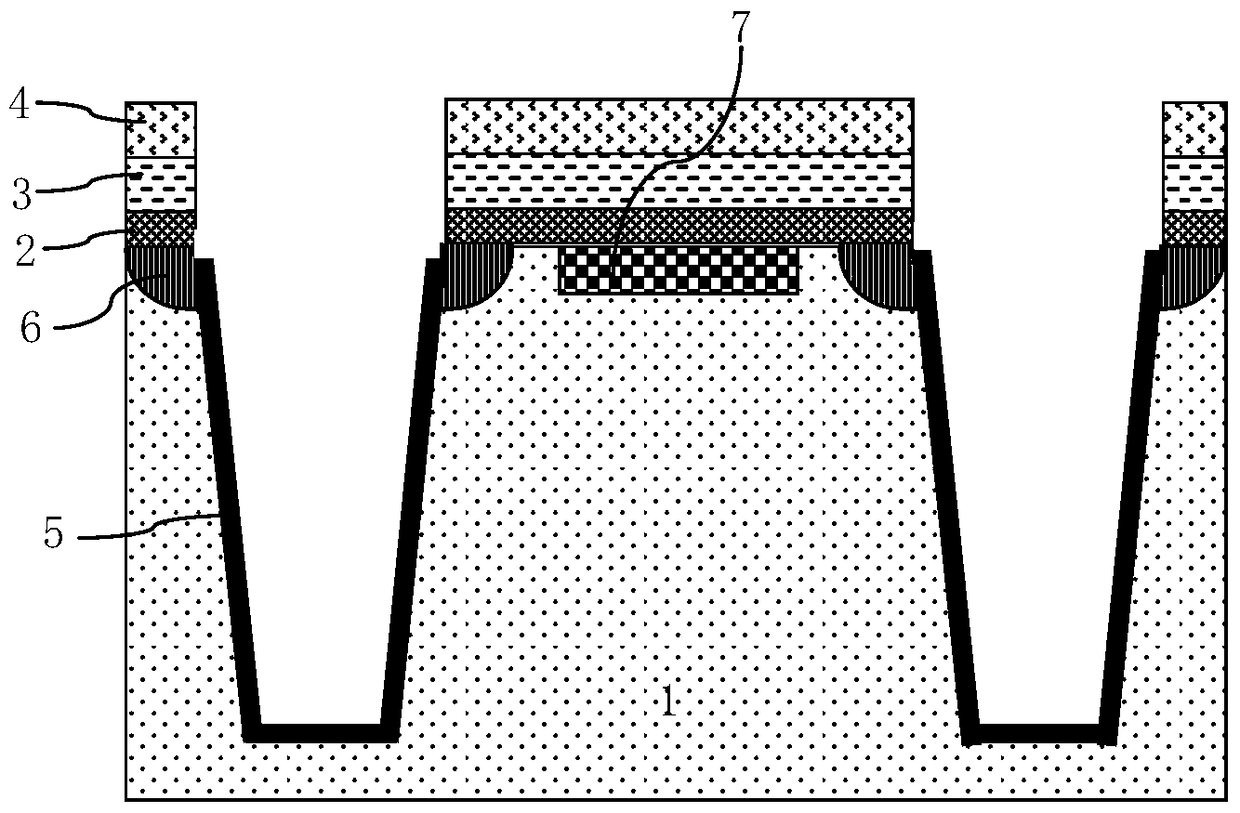

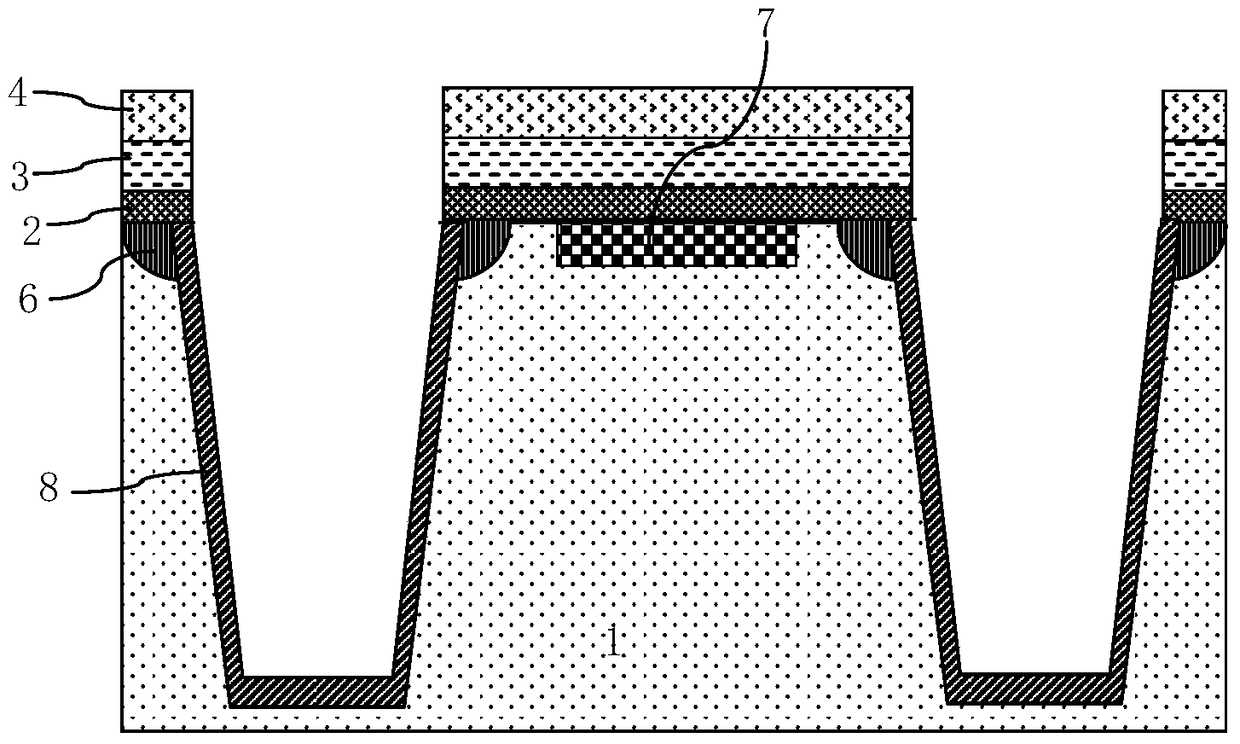

[0039] Such as figure 1 Shown is the flow chart of the method of the embodiment of the present invention; Figure 2A to Figure 2C As shown, it is a device structure diagram in each step of the method of the embodiment of the present invention; the super junction device in the embodiment of the present invention is illustrated by taking a super junction N-type MOSFET device with a working voltage of 600V and a current of 5 amps as an example, and the implementation of the present invention The manufacturing method of example superjunction device comprises following manufacturing steps:

[0040] Step 1, such as Figure 2A As shown, an N-type lightly doped silicon epitaxial substrate 1 is provided. In the embodiment of the present invention, the silicon epitaxial substrate 1 is a zone-melted silicon epitaxial substrate. The silicon epitaxial substrate 1 has a resistivity of 1 ohm·cm to 30 ohm·cm, and a thickness of more than 700 microns.

[0041] A JFET implantation process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com